Table of contents

1Introduction........................................................................................................................... 8

2Intended use.......................................................................................................................... 8

2.1 Limitation of liability.......................................................................................................... 8

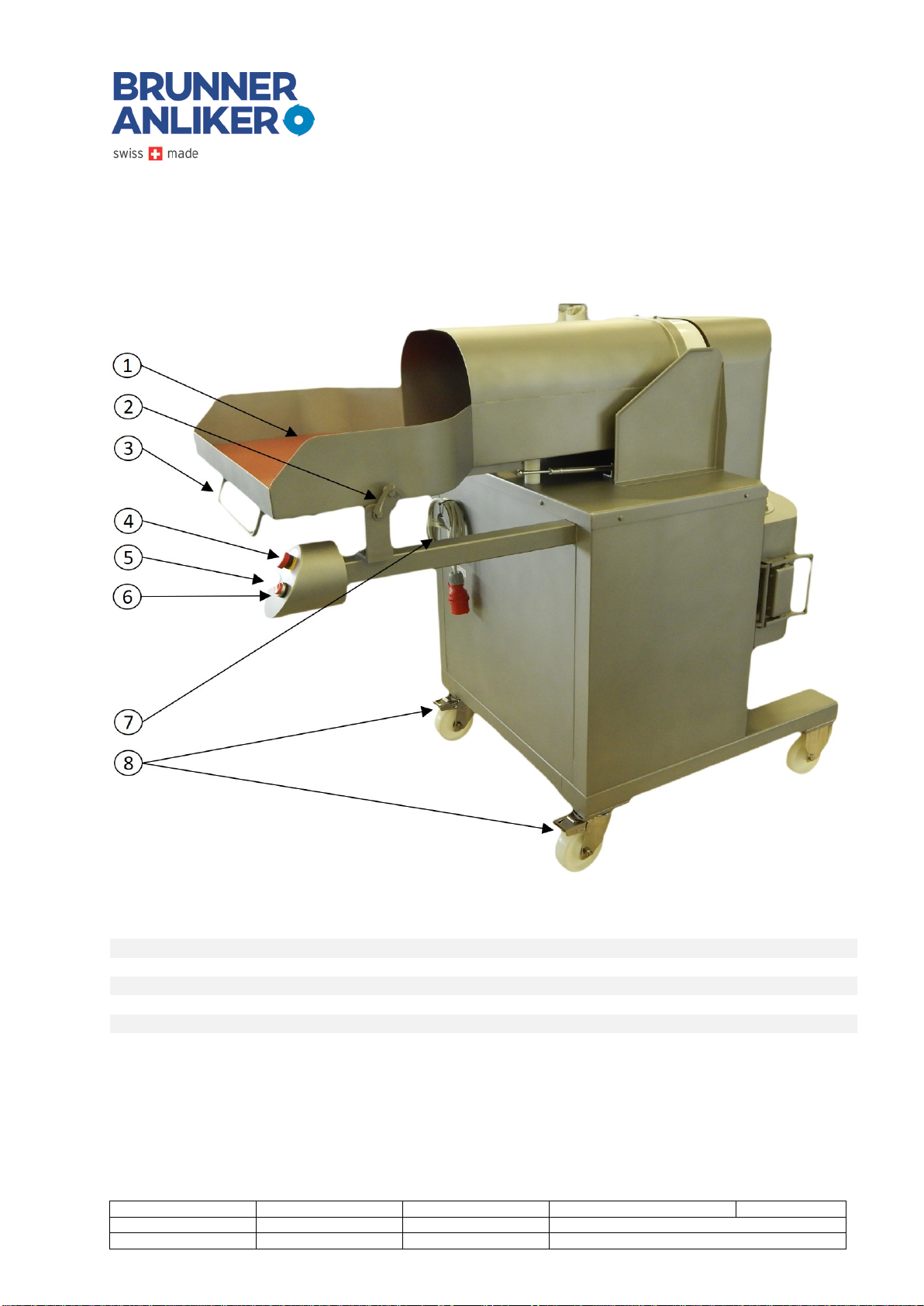

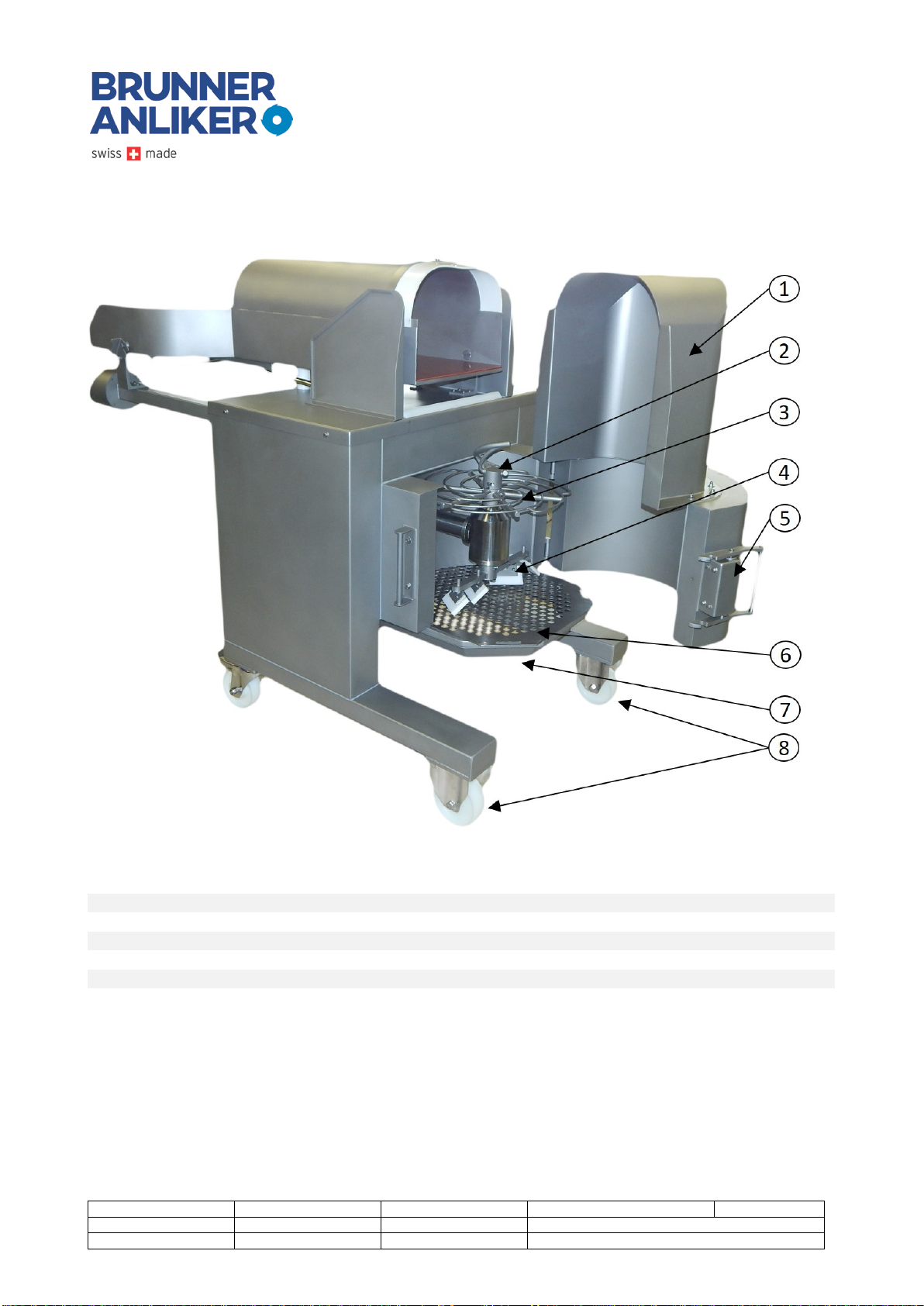

3System components ............................................................................................................... 9

3.1 Front view (operator side).................................................................................................. 9

3.2 Rear view ....................................................................................................................... 10

4Scope of supply .................................................................................................................... 11

4.1 Scope of supply............................................................................................................... 11

4.2 Accessories .................................................................................................................... 12

5Transport and installation instructions ................................................................................... 13

5.1 Consignment .................................................................................................................. 13

5.2 Start-up ......................................................................................................................... 13

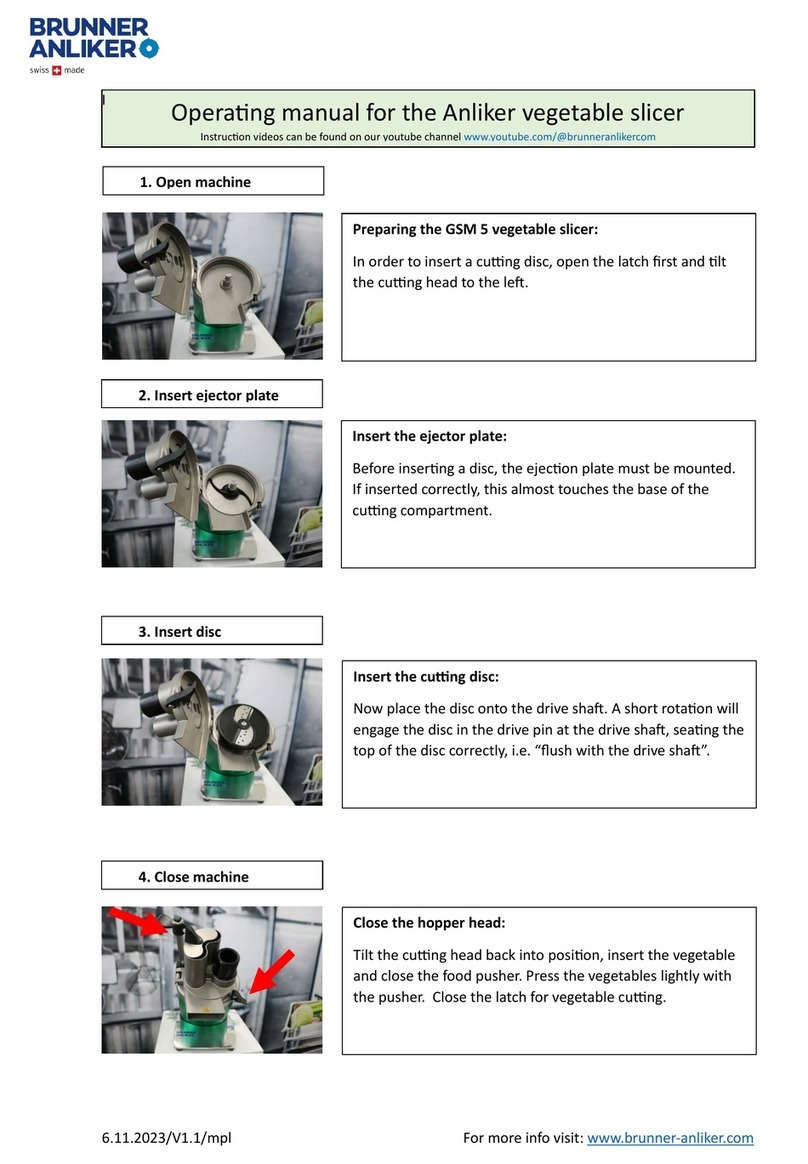

6Operation ............................................................................................................................ 14

6.1 Preparing the machine .................................................................................................... 14

6.2 Fruit processing .............................................................................................................. 18

7System maintenance............................................................................................................. 19

7.1 Cleaning......................................................................................................................... 19

8Troubleshooting ................................................................................................................... 21

8.1 Delivered fruit too big - fruit not completely declumped...................................................... 21

8.2 Delivered fruit too small - fruit crushed or cut. ................................................................... 21

8.3 Obstruction - nothing goes in, nothing goes out.................................................................. 21

8.4 Service line..................................................................................................................... 22

9Spare parts .......................................................................................................................... 22

9.1 Disposal ......................................................................................................................... 22

10 Transfer to third parties ...................................................................................................... 22

11 Technical specifications....................................................................................................... 23

11.1 Dimensional drawing....................................................................................................... 24

12 CE Conformity Declaration................................................................................................... 25

13 Warranty ........................................................................................................................... 26