2

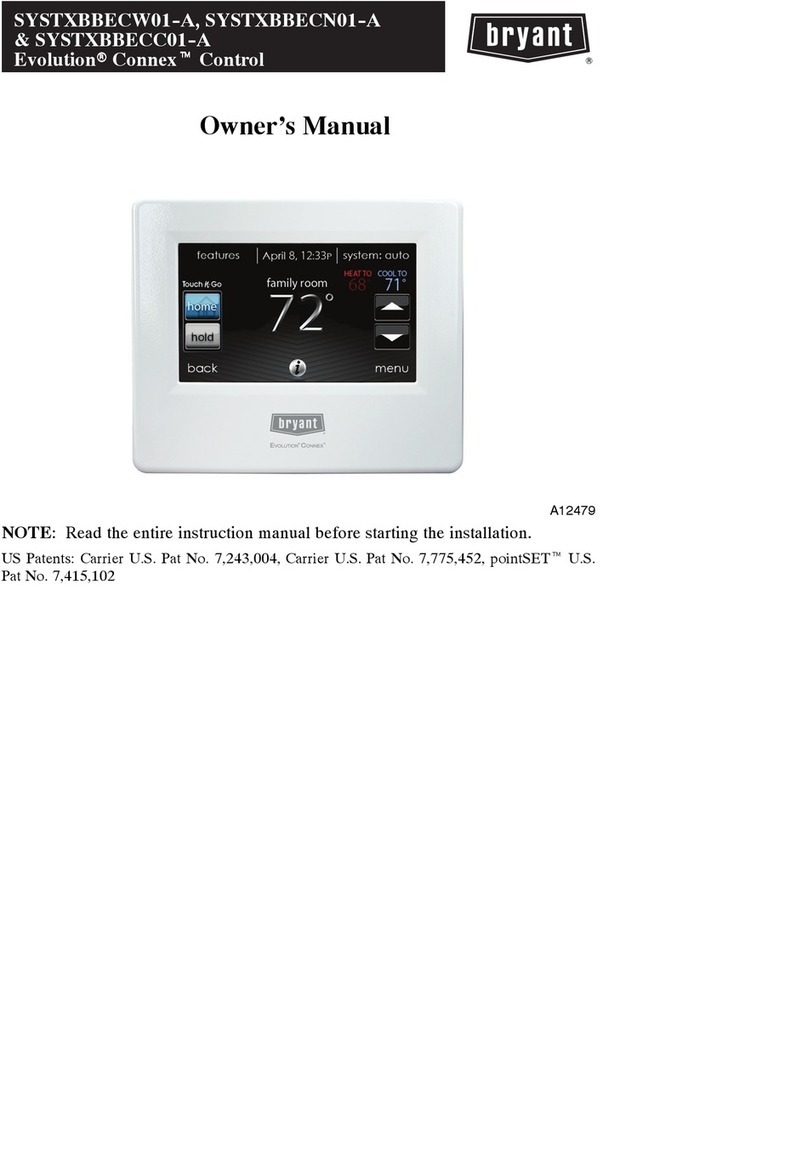

SEvolutionrConnextWall Control (p/n SYSTXCBBECC01,

SYSTXBBECW01, or SYSTXBBECN01) — Each installation

has only one Master wall/zoning control. This is the command

center for the entire system. It will typically be located in Zone 1

to sense and control the temperature in this zone. If desired, a

Remote Room Sensor or a Smart Sensor may be used to sense the

Zone 1 temperature. This can give the installer some flexibility in

locating the Master EvolutionrConnextwall control to another

area.

SRemote Room Sensor (p/n SYSTXBBRRS01) — Any zone may

use a Remote Room Sensor (including Zone 1). This is a

temperature sensor only, having no additional user inputs. In

applications where zone temperature averaging may be desired,

this may be done using 4 Remote Room Sensors in a series /

parallel wiring configuration (See Fig. 11 for Remote Room

Sensor Averaging).

SSmart Sensor (p/n SYSTXBBSMS01) — Any zone may use a

Smart Sensor (including Zone 1). It provides a temperature

display and buttons to adjust the desired temperature in that zone

only. It also displays the outdoor temperature and indoor

humidity.

Be sure to select the desired sensor type for each zone. Zone sensors

other than the EvolutionrConnextwall control must be purchased

separately. Installation Instructions for these sensors are included

with them.

INSTALLATION

Step 1 — Check Equipment and Job Site

INSPECT EQUIPMENT—File claim with shipping company,

prior to installation, if shipment is damaged or incomplete.

Step 2 — Component Location and Wiring

Considerations

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing sensor, turn off all power to unit. There may

be more than one power disconnect.

!WARNING

NOTE: All wiring must comply with national, local, and state

codes.

LOCATING EvolutionrDAMPER CONTROL

All system wiring is run back to the EvolutionrDamper Control.

Select a location near the Evolutionrfurnace or fan coil where

wiring from the EvolutionrConnextwall control, each Remote

Room Sensor or Smart Sensor, each damper actuator, and the

equipment itself can come together easily.

The EvolutionrDamper Control is approved for indoor use only

and should never be installed with any of its components exposed

to the elements. The EvolutionrDamper Control (and the zone

dampers) may be installed in any area where the temperature

remains between --4F to 158F(--20Cto70C), and where

there is no condensation. The cover must be installed to prevent

damage from other sources. Do not locate where it will be

accessible to children. It may be mounted in either vertical or

horizontal position. Remember that wiring access is likely the most

important consideration.

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

To prevent possible damage to the EvolutionrDamper

Control, do not mount on plenum, ductwork, or flush against

surface.

CAUTION

!

LOCATING MASTER ZONING WALL CONTROL

The EvolutionrConnextwall control is the command center for

the EvolutionrZone System. It should be located where it is easily

accessible and visible to home or business owner. It is also

normally the Zone 1 sensor and as such needs to be located to

properly measure the temperature in Zone 1. If these two

requirements conflict, a separate Remote Room Sensor can be

added for Zone 1.

When a Remote Room Sensor is connected to Zone 1 terminals

(ZS1 and ZS1C) of the EvolutionrDamper Control, the system

automatically switches to using this sensor for Zone 1 and ignores

the sensor within the EvolutionrConnextwall control. This

arrangement allows the EvolutionrConnextwall control to be

located at any convenient place within the home or business. In this

arrangement, only the Zone 1 Remote Room Sensor must be

located in Zone 1.

NOTE: The EvolutionrConnextwall control also controls

humidity functions. If the wall control is not used to control Zone 1

temperature, it must still be located in a suitable area where

humidity control will not be affected.

LOCATING SENSORS

For proper operation, each sensor must accurately measure the

temperature within its zone. For accurate temperature

measurement, the following guidelines should be followed:

Sensor should be mounted:

SApproximately 5 ft. (1.5m) from floor.

SClose to the center of its zone, preferably on an inside wall.

SOn a section of wall without pipes or duct work.

Sensor should NOT be mounted:

SClose to a window, on an outside wall, or next to a door leading to

the outside.

SWhere it will be exposed to direct light and heat from a lamp, sun,

fireplace, or other temperature radiating object which may cause a

false reading.

SClose to or in direct airflow from supply registers.

SIn areas with poor air circulation, such as behind a door or in an

alcove.

WIRING CONSIDERATIONS

Ordinary thermostat wire is ideal when wiring the Evolutionr

Zoning System (shielded cable is not necessary). Use 20 AWG or

larger for typical installations. Lengths over 100 ft. should use 18

AWG or larger wire. Remote Room Sensors require only two

conductors, but it is recommended that at least four conductors be

run. This will allow a Smart Sensor to replace the Remote Room

Sensor with no wiring changes at a later date. The Evolutionr

Connextwall control requires four conductors, each damper

actuator requires three conductors. Cut off or fold back and tape

any unneeded wires. Plan the routing of wiring early to avoid

possible problems later. Remember, all wires converge at the

EvolutionrDamper Control, so its location is important.