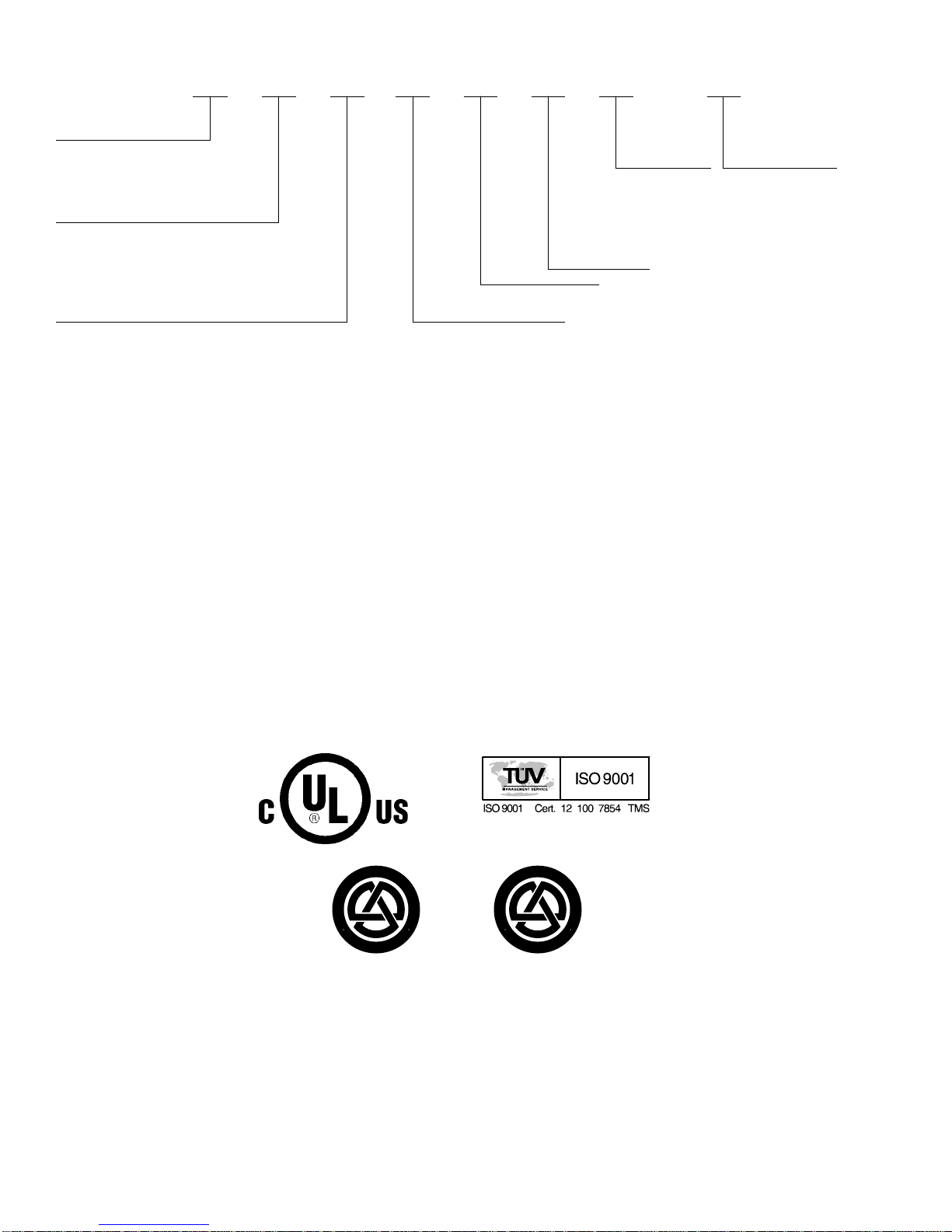

—4—

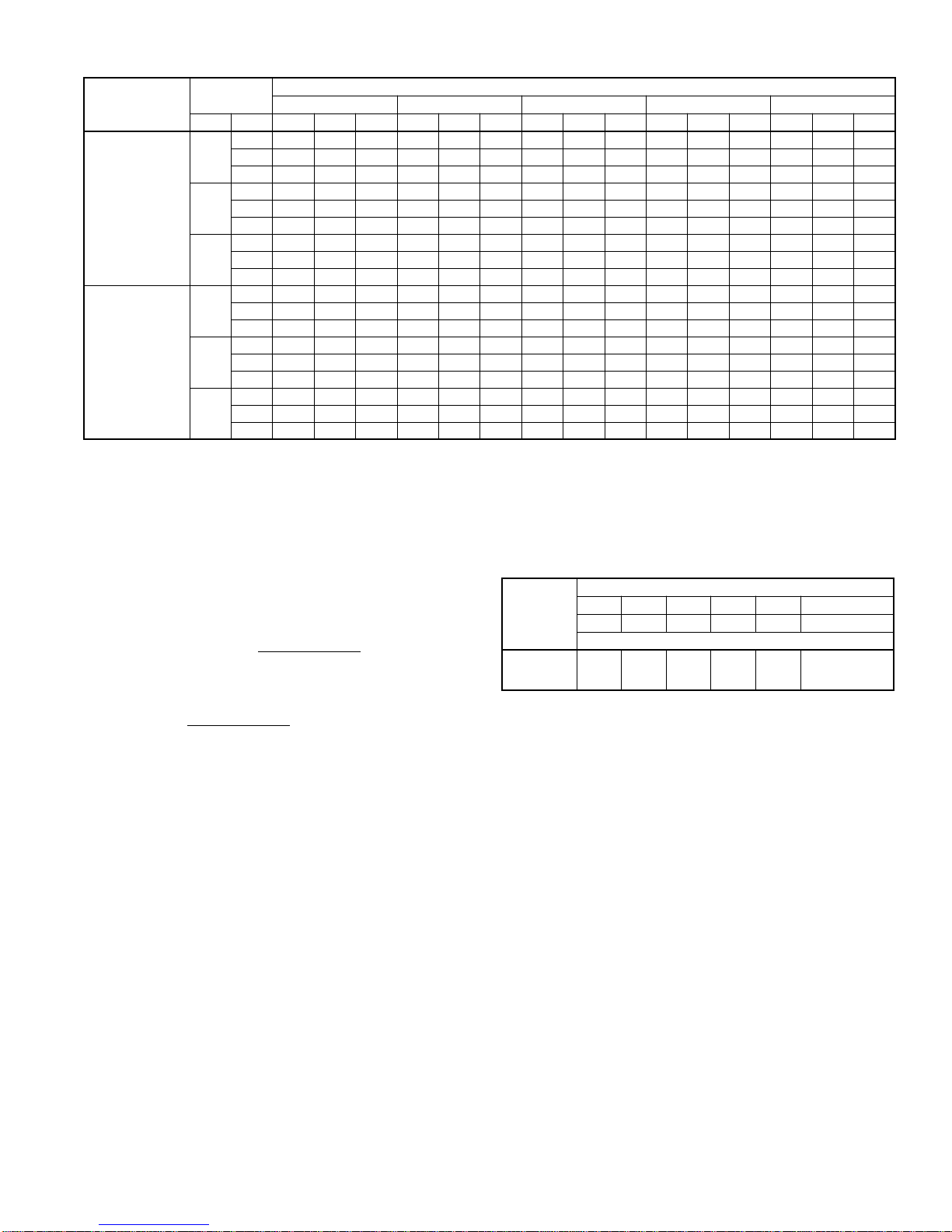

GROSS COOLING CAPACITIES (MBH)

CFM

— Cubic Ft per Minute

EWB

— Entering Wet Bulb (°F)

TC

— Gross Cooling Capacity 1000 Btuh

SHC

— Gross Sensible Capacity 1000 Btuh

BF

— Bypass Factor

MBH

— 1000 Btuh

UNIT

SIZE

INDOOR COIL

AIR SATURATED TEMPERATURE LEAVING EVAPORATOR (°F)

30 35 40 45 50

CFM EWB TC SHC BF TC SHC BF TC SHC BF TC SHC BF TC SHC BF

A018

450 72 31.9 14.8 0.00 28.9 13.4 0.00 26.0 12.1 0.00 22.6 10.7 0.07 18.5 9.04 0.06

67

26.8 15.8 0.07 23.7 14.3 0.06 20.5 12.8 0.05 16.7 11.2 0.04 12.5 9.40 0.05

62

21.8 16.6 0.04 18.6 14.9 0.04 15.4 13.3 0.05 12.3 11.7 0.08 9.95 9.95 0.18

600 72 37.5 17.3 0.00 34.0 15.8 0.00 30.5 14.2 0.16 26.5 12.6 0.11 22.1 10.9 0.09

67

31.3 18.7 0.10 27.8 17.1 0.09 24.3 15.5 0.08 20.1 13.7 0.07 15.2 11.7 0.09

62

25.8 20.1 0.08 22.2 18.4 0.08 18.6 16.6 0.08 15.2 14.7 0.11 12.5 12.5 0.22

750 72 41.7 19.2 0.00 37.9 17.6 0.00 34.0 16.0 0.17 29.6 14.2 0.14 24.7 12.4 0.12

67

35.1 21.2 0.13 31.0 19.5 0.12 26.9 17.7 0.11 22.6 15.9 0.11 17.4 13.7 0.12

62

28.4 22.9 0.10 24.9 21.3 0.10 21.4 19.6 0.11 17.7 17.5 0.14 14.8 14.8 0.26

A024

W024

600 72 38.7 17.9 0.00 35.4 16.4 0.00 32.0 15.0 0.13 28.1 13.3 0.08 23.7 11.6 0.07

67

32.6 19.5 0.07 29.1 17.9 0.06 25.6 16.3 0.06 21.5 14.5 0.05 16.6 12.5 0.06

62

27.0 20.9 0.05 23.4 19.2 0.05 19.8 17.4 0.05 16.2 15.5 0.08 13.3 13.3 0.18

800 72 44.0 20.4 0.21 40.4 18.9 0.17 36.8 17.3 0.13 32.4 15.6 0.11 27.2 13.7 0.10

67

37.4 22.8 0.10 33.5 21.1 0.10 29.5 19.4 0.09 25.0 17.5 0.08 19.7 15.4 0.09

62

30.6 25.0 0.07 27.0 23.2 0.08 23.4 21.4 0.09 19.7 19.3 0.12 16.6 16.6 0.23

1000 72 47.9 22.3 0.18 44.0 20.7 0.17 40.1 19.2 0.16 35.5 17.4 0.14 30.0 15.4 0.13

67

40.7 25.5 0.13 36.6 23.8 0.13 32.4 22.0 0.12 27.3 20.0 0.11 21.9 17.9 0.12

62

33.7 28.6 0.10 30.0 26.7 0.11 26.2 24.9 0.12 22.7 22.5 0.17 19.4 19.4 0.28

A030

W030

750 72 54.4 25.3 0.00 48.7 22.7 0.00 43.1 20.1 0.00 36.6 17.3 0.07 29.3 14.5 0.06

67

45.1 26.5 0.07 39.1 23.7 0.07 33.2 20.9 0.06 26.7 18.1 0.05 20.0 15.2 0.08

62

36.0 27.3 0.05 30.5 24.5 0.06 25.0 21.8 0.07 19.7 19.0 0.09 16.1 16.1 0.21

1000 72 64.1 29.5 0.00 57.7 26.7 0.00 51.2 23.9 0.19 43.9 20.9 0.12 35.2 17.6 0.10

67

53.6 31.8 0.11 46.8 28.7 0.10 40.1 25.6 0.10 32.3 22.3 0.09 24.1 18.8 0.11

62

43.4 33.4 0.10 36.9 30.3 0.10 30.4 27.2 0.10 24.3 24.0 0.12 20.1 20.1 0.26

1250 72 72.1 33.0 0.00 64.7 29.9 0.00 57.3 26.8 0.20 49.4 23.7 0.15 40.1 20.3 0.14

67

59.6 35.8 0.14 52.4 32.7 0.14 45.3 29.5 0.13 36.8 25.9 0.13 27.5 22.0 0.15

62

49.0 38.4 0.14 42.0 35.2 0.13 35.0 32.1 0.13 28.6 28.4 0.16 23.7 23.7 0.30

A036

N036

T036

W036

900 72 63.4 29.6 0.00 57.2 26.8 0.00 50.9 23.9 0.00 44.3 21.0 0.00 36.3 17.9 0.00

67

52.1 31.0 0.00 46.0 28.1 0.00 39.8 25.1 0.00 32.8 22.1 0.00 24.9 18.8 0.01

62

42.8 32.7 0.00 36.7 29.6 0.00 30.5 26.6 0.01 23.9 23.0 0.04 19.2 19.2 0.18

1200 72 75.1 34.7 0.00 67.8 31.6 0.00 60.5 28.5 0.05 52.1 25.1 0.03 43.4 21.8 0.02

67

61.6 37.2 0.02 54.5 34.0 0.02 47.5 30.8 0.02 39.3 27.3 0.02 30.2 23.4 0.04

62

51.1 40.2 0.02 44.0 36.7 0.03 36.9 33.2 0.03 29.3 28.9 0.08 24.2 24.2 0.22

1500 72 83.3 38.5 0.17 75.5 35.3 0.13 67.6 32.1 0.09 58.5 28.5 0.06 48.4 24.8 0.06

67

69.4 42.5 0.06 61.3 38.9 0.06 53.1 35.4 0.05 44.4 31.7 0.05 34.5 27.5 0.07

62

56.6 46.2 0.04 49.3 42.5 0.06 42.0 38.8 0.07 34.3 34.3 0.11 28.8 28.8 0.25

A042

N042

T042

1050 72 75.4 35.0 0.00 68.0 31.8 0.00 60.7 28.6 0.02 52.7 25.3 0.00 43.6 21.7 0.00

67

62.1 37.3 0.00 55.0 34.0 0.00 47.8 30.7 0.00 39.3 26.9 0.01 30.2 23.1 0.03

62

51.5 39.8 0.01 44.2 36.2 0.01 36.9 32.7 0.02 29.1 28.3 0.06 23.7 23.7 0.20

1400 72 87.8 40.6 0.18 79.4 37.1 0.13 71.0 33.6 0.07 61.3 29.8 0.05 51.0 25.9 0.05

67

72.9 44.4 0.05 64.4 40.7 0.04 55.9 36.9 0.04 46.7 33.0 0.04 36.1 28.5 0.06

62

60.0 48.3 0.03 52.0 44.3 0.05 44.0 40.3 0.06 35.5 35.5 0.10 29.7 29.7 0.24

1750 72 96.3 44.6 0.16 87.4 41.1 0.13 78.5 37.5 0.11 67.9 33.5 0.09 55.9 29.1 0.09

67

80.8 50.1 0.08 71.5 46.1 0.08 62.2 42.2 0.08 51.9 37.9 0.08 40.9 33.4 0.10

62

65.7 55.1 0.07 57.6 50.9 0.08 49.5 46.6 0.10 41.7 41.7 0.15 35.0 35.0 0.28

A048

N048

T048

W048

1200 72 79.8 36.9 0.00 72.6 33.7 0.00 65.4 30.6 0.12 57.0 27.1 0.08 47.5 23.4 0.07

67

66.6 39.8 0.07 59.1 36.4 0.06 51.7 33.0 0.06 43.2 29.3 0.05 33.3 25.2 0.07

62

55.2 42.8 0.06 47.6 39.1 0.06 40.0 35.4 0.06 32.2 31.3 0.08 26.7 26.7 0.20

1600 72 91.0 42.1 0.22 83.0 38.7 0.18 75.0 35.4 0.13 65.4 31.7 0.11 54.5 27.6 0.10

67

76.7 46.9 0.10 68.1 43.1 0.10 59.5 39.4 0.09 50.1 35.4 0.09 39.4 31.0 0.11

62

62.7 51.0 0.08 54.9 47.2 0.09 47.1 43.4 0.10 39.3 39.0 0.13 33.1 33.1 0.25

2000 72 99.2 46.1 0.19 90.7 42.7 0.17 82.2 39.4 0.15 72.0 35.5 0.14 60.0 31.2 0.13

67

84.0 52.6 0.13 74.8 48.8 0.13 65.7 44.9 0.12 55.1 40.5 0.12 44.0 36.0 0.13

62

69.0 58.5 0.11 60.8 54.3 0.12 52.6 50.2 0.14 45.4 45.4 0.18 38.5 38.5 0.30