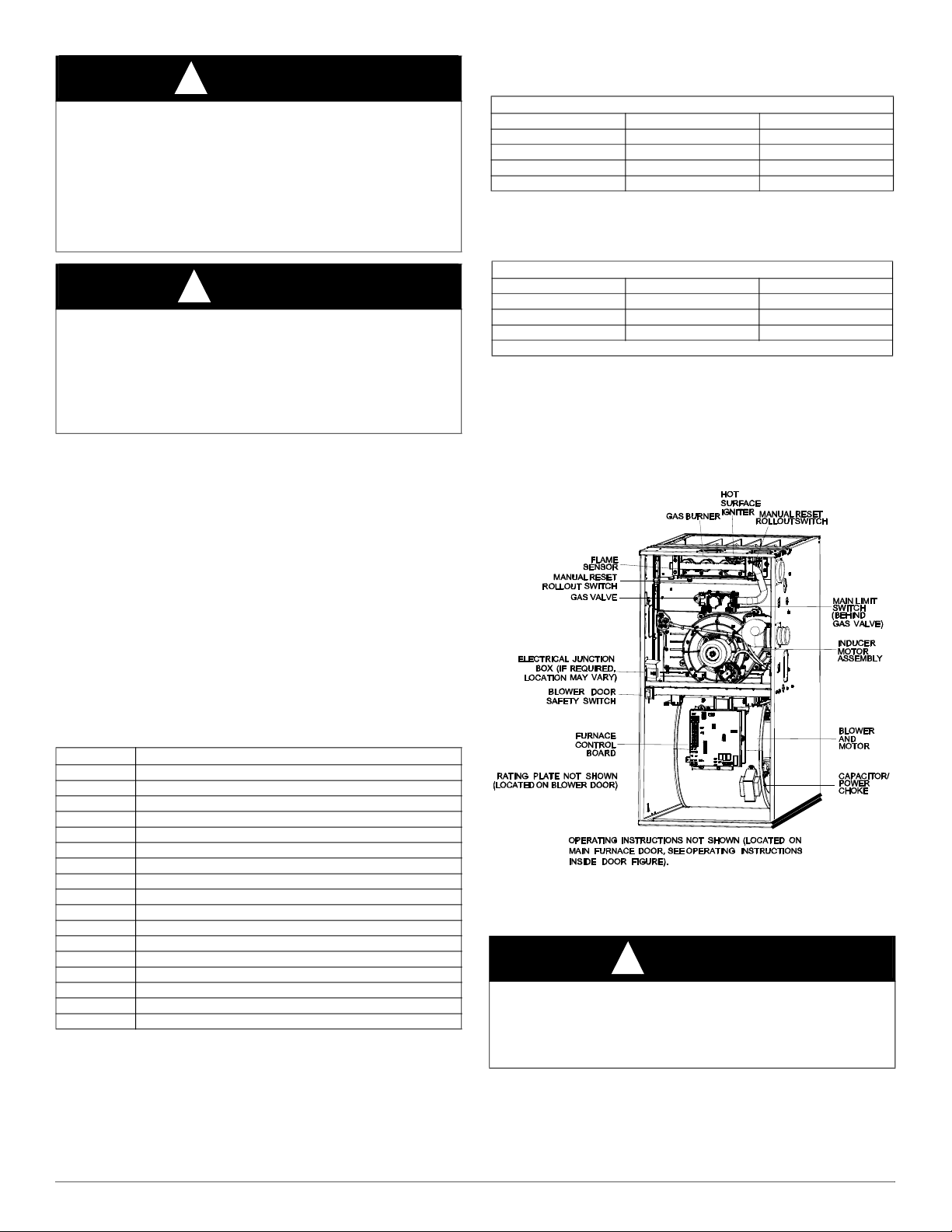

Installation Instructions

NOTE: Read the entire instruction manual before starting the

installation.

A200203

SAFETY CONSIDERATION

Installing and servicing heating equipment can be hazardous due to gas

and electrical components. Only trained and qualified personnel should

install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions such as

cleaning and replacing air filters. Trained service personnel must

perform all other operations. When working on heating equipment,

observe precautions in the literature, on tags, and on labels attached to or

shipped with the unit, and other safety precautions that may apply.

Follow all safety codes. In the United States, follow all safety codes

including the current edition of the National Fuel Gas Code (NFGC)

NFPA No. 54/ANSI Z223.1. In Canada, refer to the current edition of the

National Standard of Canada, Natural Gas and Propane Installation

Codes (NSCNGPIC), CAN/CSA-B149.1 and .2. Wear safety glasses and

work gloves. Have a fire extinguisher available during start-up,

adjustment steps, and service calls.

Recognize safety information. This is the safety-alert symbol . When

you see this symbol on the furnace and in instructions or manuals, be

alert to the potential for personal injury. Understand the signal words

DANGER, WARNING, CAUTION and NOTE. The words DANGER,

WARNING, and CAUTION are used with the safety alert symbol.

DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which could

result in personal injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which will

result in enhanced installation, reliability, or operation.

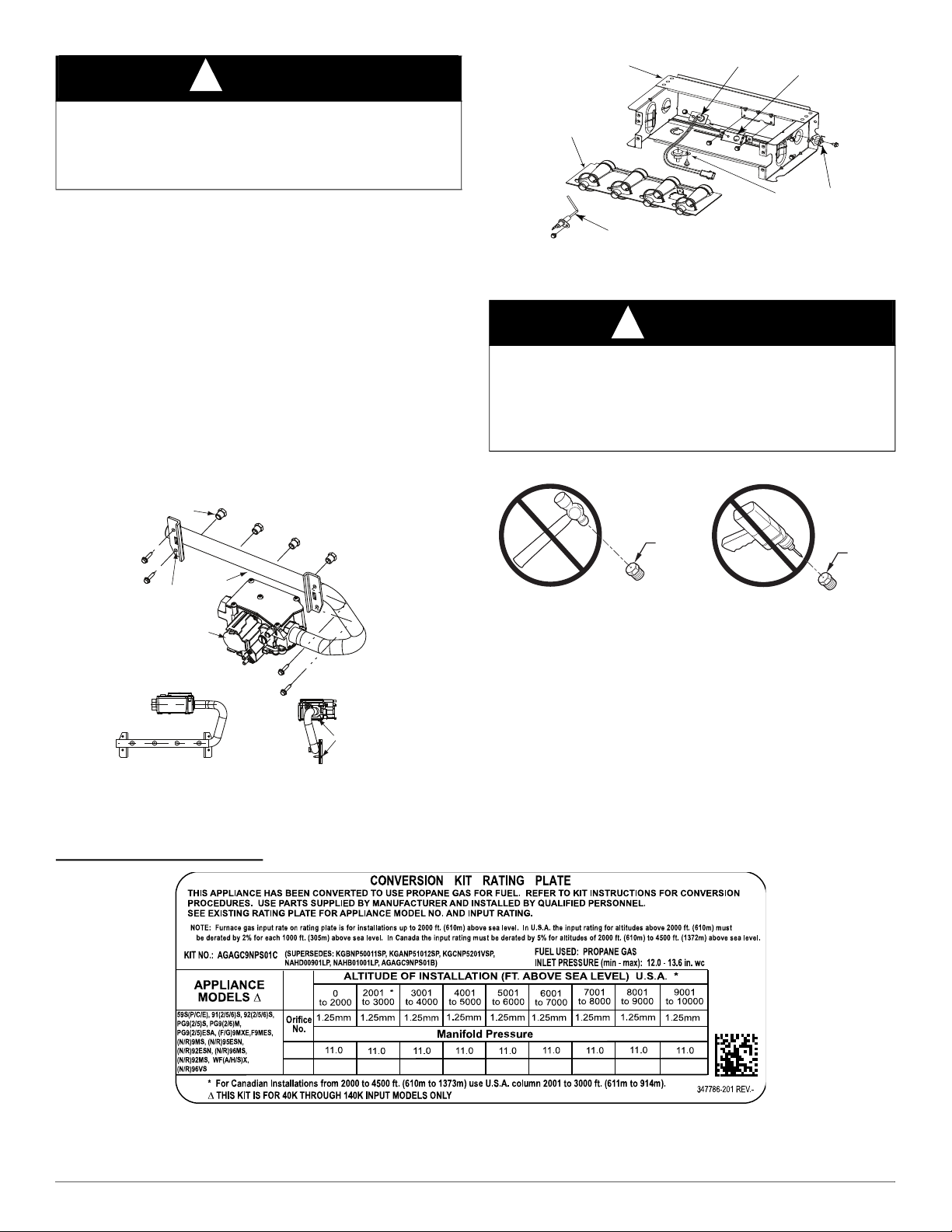

INTRODUCTION

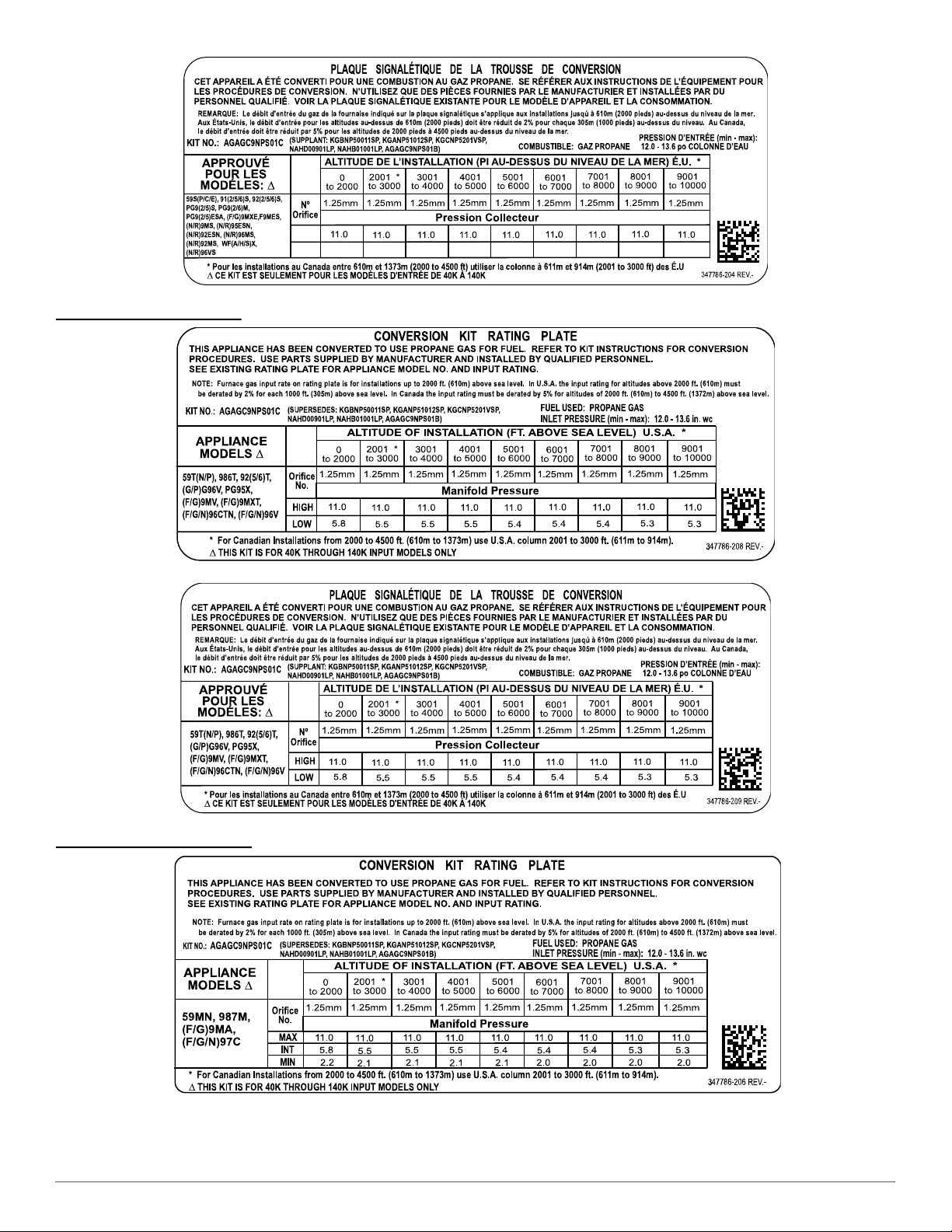

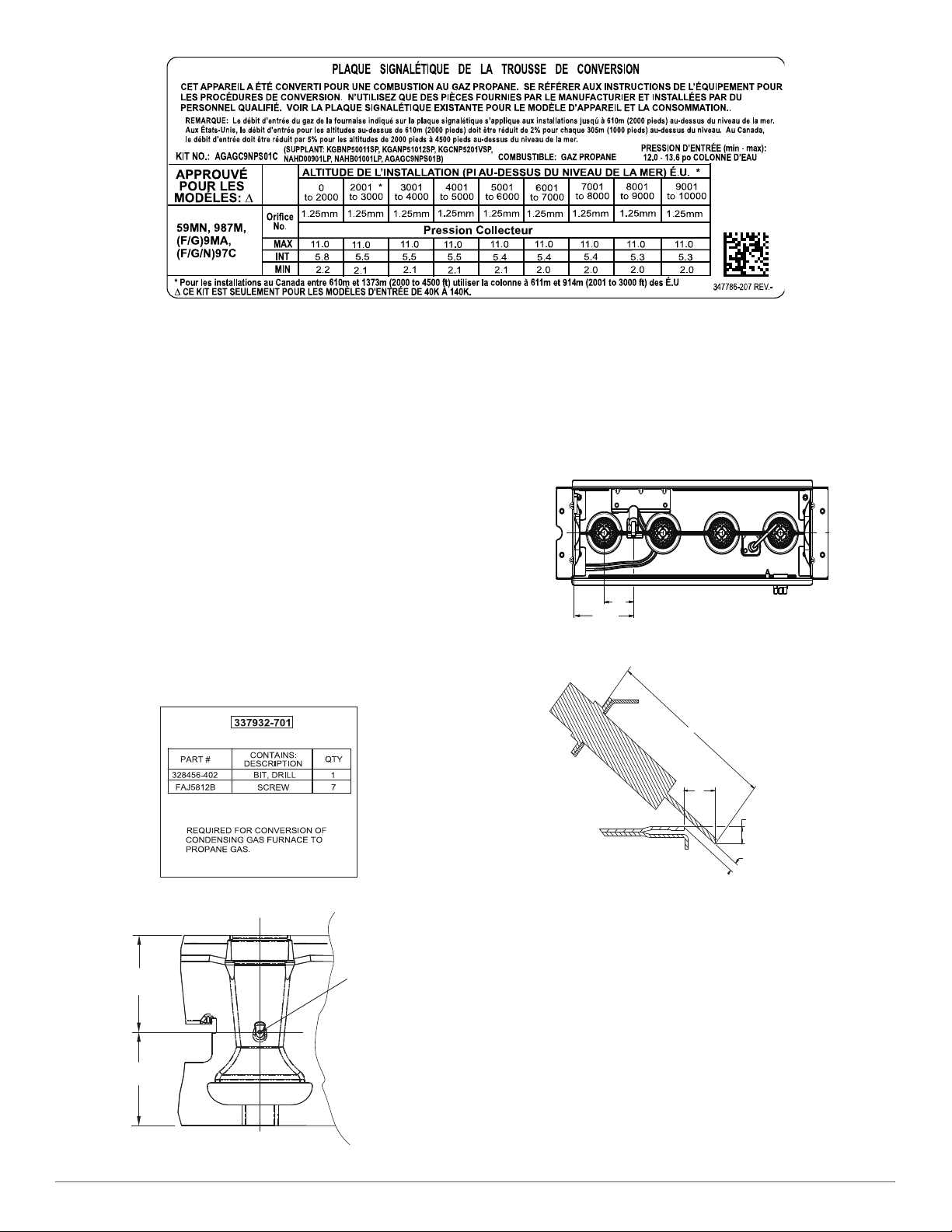

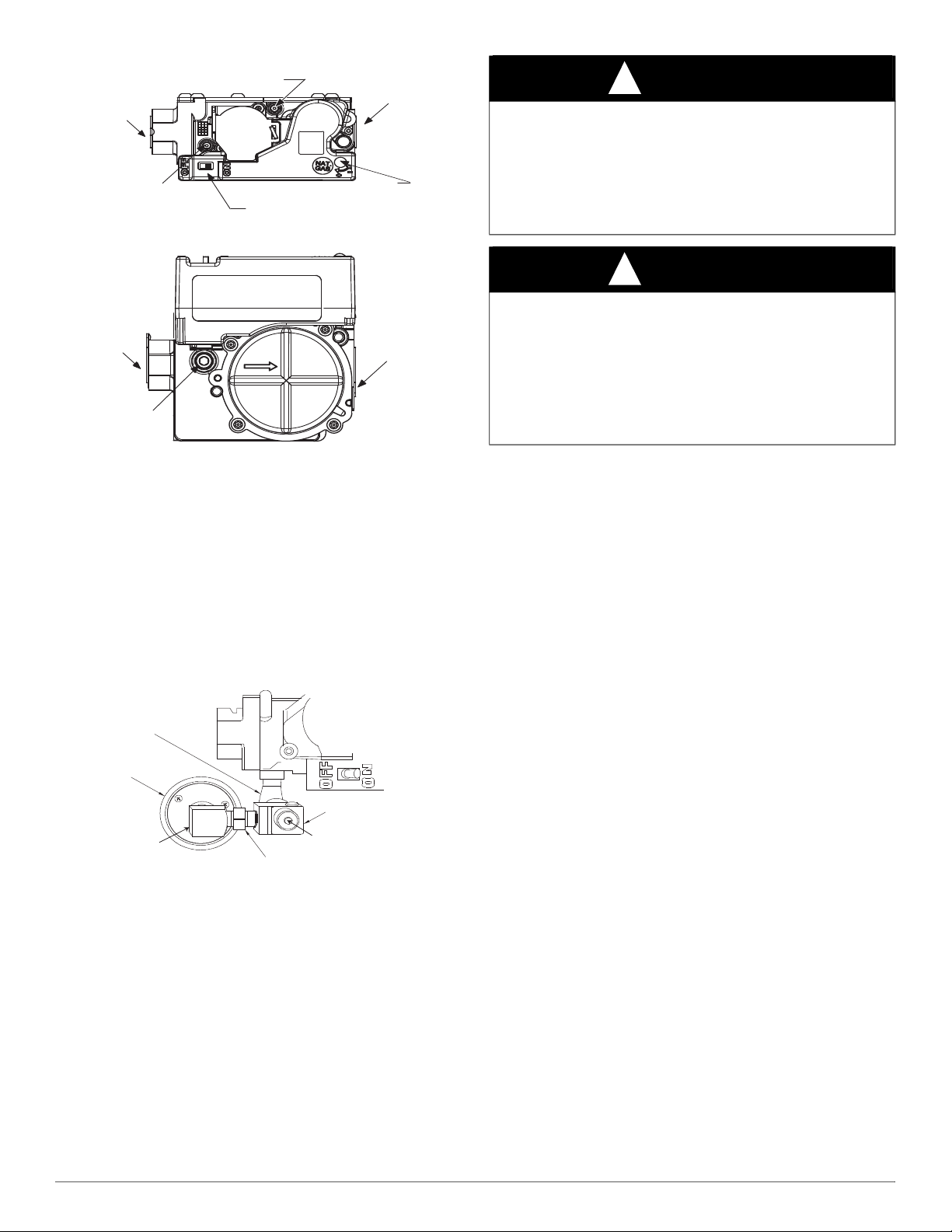

AGAGC9NPS01C

Gas Conversion Kit, Natural to Propane

Condensing (90%+) Furnaces

40,000 BTUH to 140,000 BTUH Models Only

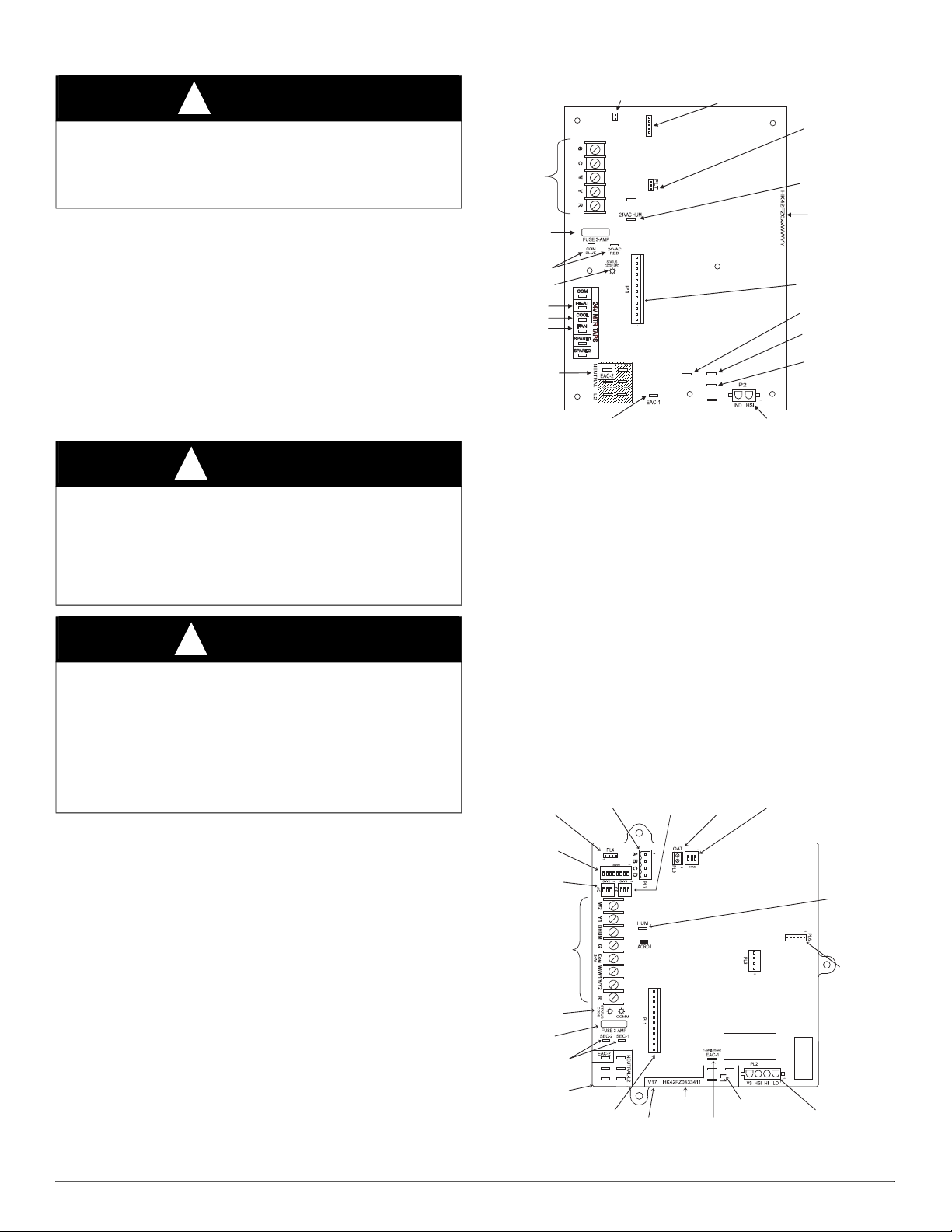

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

This conversion kit shall be installed by a qualified service agency in

accordance with the manufacturer’s instructions and all applicable

codes and requirements of the authority having jurisdiction. If the

information in these instructions is not followed exactly, a fire,

explosion, or production of carbon monoxide could result causing

property damage, personal injury, or loss of life. The qualified service

agency is responsible for the proper installation of this furnace with this

kit. The installation is not proper and complete until the operation of the

converted appliance is checked as specified in the manufacturer’s

instructions supplied with the kit

AVERTISSEMENT

!

LE FEU, L’EXPLOSION, CHOC ELECTRIQUE,

ET MONOXYDE DE CARBONE EMPOISONNER

Cette trousse de conversion doit être installée par un servie d’entretien

qualifié, selon les instructions du fabricant et selon toutes les exigences

et tous les codes pertinents de l’autorité compétente. Assurezvous de

bien suivre les instructions dans cette notice pour réduire au minimum

le risque d’incendie, d’explosion ou la production de monoxyde de

carbone pouvant causer des dommages matériels, de blessure ou la

mort. Le service d’entretien qualifié est responsable de l’installation de

cette trousse. L’installation n’est pas adéquate ni complète tant que le

bon fonctionnement de l’appereil converti n’a pas été vérfié selon les

instructions du fabricant fornies avec la trousse.

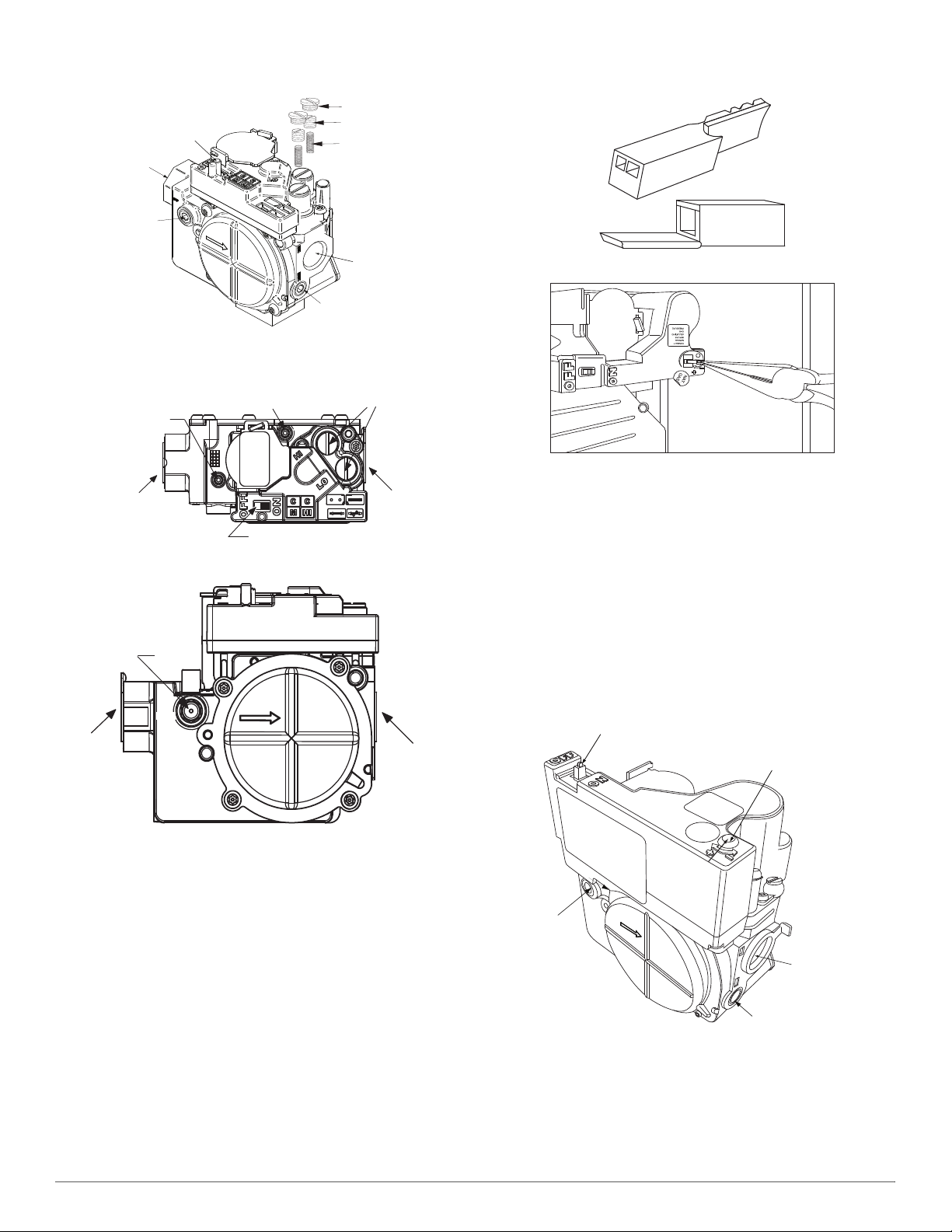

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow instructions could result in personal injury, death or

property damage.

Improper installation, adjustment, alteration, service, maintenance, or

use can cause carbon monoxide poisoning, explosion, fire, electrical

shock, or other conditions, which could result in personal injury or

death. Consult your distributor or branch for information or assistance.

The qualified installer or agency must use only factory-authorized kits

or accessories when servicing this product.

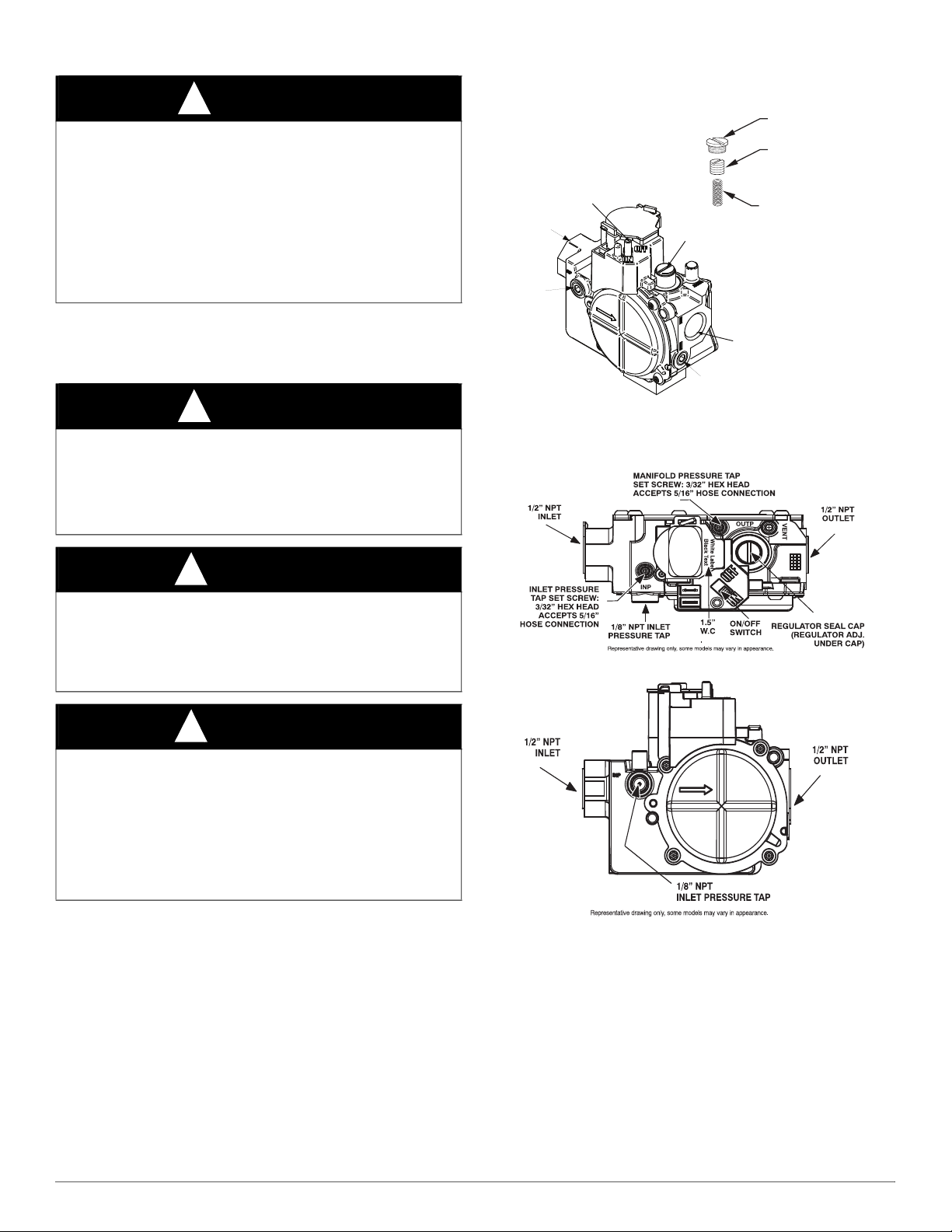

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury, death or

property damage.

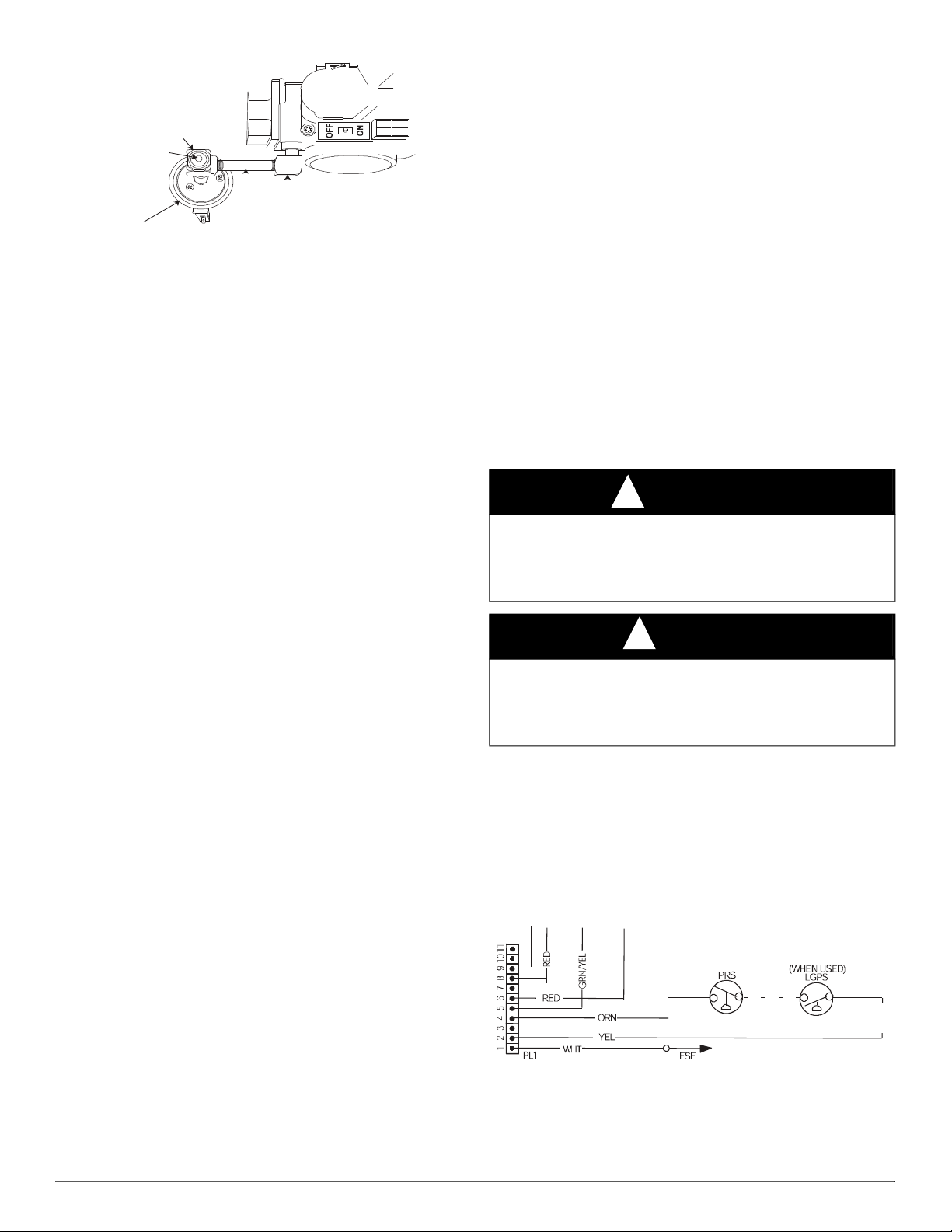

Gas supply MUST be shut off before disconnecting electrical power

and proceeding with conversion.