NOTE: Read the entire instruction manual before starting the installation.

This symbol →indicates a change since the last issue.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS.....................................................................................................................................................................................1

INTRODUCTION..........................................................................................................................................................................................................2

DESCRIPTION AND USAGE .....................................................................................................................................................................................2

ELECTROSTATIC DISCHARGE (ESD) PRECAUTION .........................................................................................................................................4

SECTION I: MULTIPOISE SINGLE-SPEED AND TWO-SPEED NON-CONDENSING HSI FURNACE MODELS ........................................4

Install Furnaces.........................................................................................................................................................................................................4

Upflow/Downflow, Side-by-Side Position .........................................................................................................................................................4

Upflow/Downflow, Back-to-Back Position........................................................................................................................................................7

Horizontal, Back-to-Back Position .....................................................................................................................................................................8

Horizontal, Stacked Together ...........................................................................................................................................................................10

Connect Electrical Components—Heating ............................................................................................................................................................11

All Single-Stage Models: 58STA, 58STX, 58DLA, 58DLX, 310AAV, 310JAV, 311AAV, 311JAV, PG8MAA, AND PG8JAA

Multipoise Single-Speed Non-Condensing HSI Furnaces...............................................................................................................................11

All Two-Stage Models: 58CTA, 58CTX, 312AAV, 312JAV Multipoise Two-Speed Non-Condensing HSI Furnaces with PSC

Motors................................................................................................................................................................................................................15

Connect Electrical Components-Cooling...............................................................................................................................................................17

Venting....................................................................................................................................................................................................................17

Gas Supply Piping..................................................................................................................................................................................................17

Electrical Supply Connections ...............................................................................................................................................................................17

Start-Up and Adjustment........................................................................................................................................................................................19

Sequence of Operation ...........................................................................................................................................................................................21

SECTION II: SINGLE-SPEED AND TWO-SPEED MULTIPOISE CONDENSING HSI FURNACE MODELS...............................................22

Install Furnaces.......................................................................................................................................................................................................22

Upflow, Downflow, Side-By-Side Configuration............................................................................................................................................22

Upflow/Downflow, Back-to-Back Configuration ............................................................................................................................................27

Horizontal, Back-to-Back Configuration..........................................................................................................................................................28

Connect Electrical Components—Heating ............................................................................................................................................................30

Connect Electrical Components—Cooling ............................................................................................................................................................33

Venting....................................................................................................................................................................................................................34

Gas Supply Piping..................................................................................................................................................................................................34

Condensate Drain Connections ..............................................................................................................................................................................34

Electrical Supply Connections ...............................................................................................................................................................................34

Start-Up and Adjustment........................................................................................................................................................................................34

Sequence of Operation ...........................................................................................................................................................................................36

Fixed Capacity Furnaces...................................................................................................................................................................................36

SAFETY CONSIDERATIONS

Installing and servicing of heating equipment can be hazardous due to gas and electrical components. Only trained personnel should install or

service heating equipment.

Untrained personnel can perform basic maintenance such as cleaning and replacing filters. All other operations should be performed by trained

service personnel. When working on heating equipment, observe precautions in the literature, on tags, and on labels attached to the unit.

Follow all safety codes. Wear safety glasses and work gloves. Have a fire extinguisher available.

Recognize safety information. This is the safety-alert symbol . When you see this symbol on the furnace and in instructions or manuals, be

alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used with the safety-alert symbol. DANGER

identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies a hazard which could result in

personal injury or death. CAUTION is used to identify unsafe practices which would result in minor personal injury or product and property

damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

Installation Instructions

KGATW0601HSI

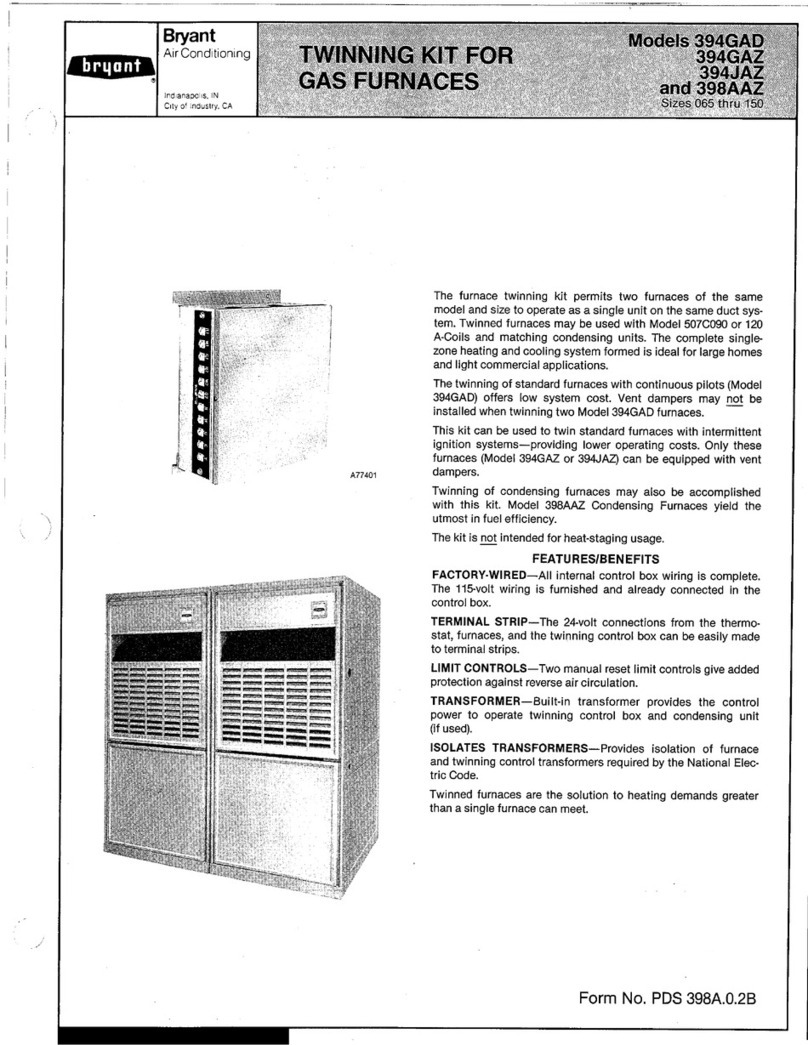

Twinning Kit for HSI Single-and

2-Stage Upflow Condensing and

Non-Condensing Gas Furnaces

Catalog No.: AG-GATW-15 Cancels: AG-GATW-14 Printed in U.S.A. 10-05

→