1

337938---782---CBP

337938---784---CBP

337938---785---CBP

337938---786---CBP

337938---787---CBP

337938---790---CBP

Installation Instructions

INDUCER HOUSING KIT

F O R S I N G L E --- S T A G E , T W O --- S T A G E A N D

MODULATING GAS FURNACES

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product. Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes, the current editions of the National Fuel Gas Code

(NFGC) NFPA 54/ANSI Z223.1 and the National Electrical Code

(NEC) NFPA 70.

In Canada, refer to the current editions of the National Standards of

Canada CAN/CSA--B149.1 and .2 Natural Gas and Propane

Installation Codes, and Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety--alert symbol .

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER,WARNING,and

CAUTION. These words are used with the safety--alert symbol.

DANGER identifies the most serious hazards which will result in

severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

FIRE, EXPLOSION, ELECTRICAL SHOCK

HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

The ability to properly perform maintenance on this equipment

requires certain knowledge, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any maintenance on this equipment other than those

procedures recommended in the Owner’s Manual.

!WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow instructions could result in personal injury,

death or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poisoning,

explosion, fire, electrical shock, or other conditions, which

could result in personal injury or death. Consult your

distributor or branch for information or assistance. The

qualified installer or agency must use only factory--authorized

kits or accessories when servicing this product.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag. There may be more than one electrical

supply to the furnace. Check accessories and cooling unit for

additional electrical supplies that must be shut off during

furnace servicing. Lockout and tag switch with a suitable

warning label. Verify proper operation after servicing.

!WARNING

INTRODUCTION

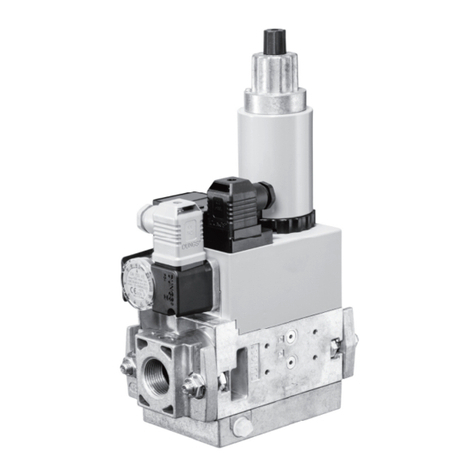

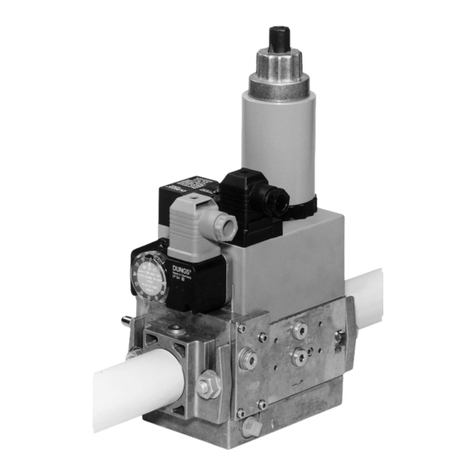

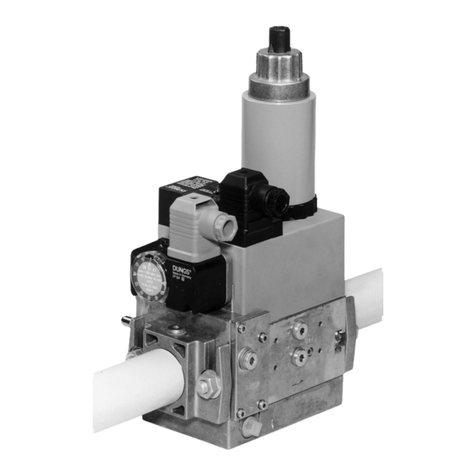

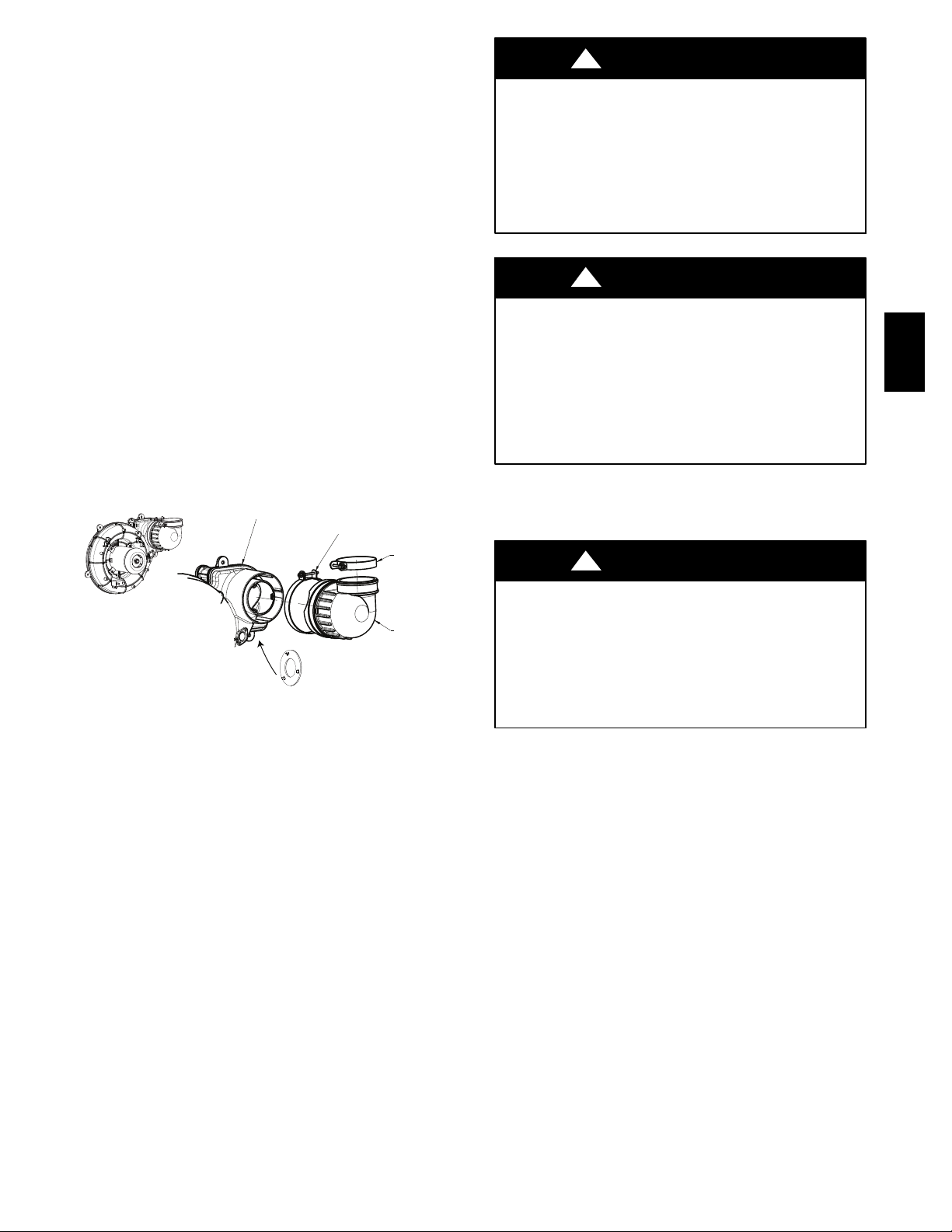

This instruction covers installation of the single--speed, two--speed,

and modulating inducer assemblies on condensing 35--in. (889

mm) tall, high--efficiency units.

The inducer should be replaced when the motor is seized, open,

shorted or grounded. The PSC motor is equipped with an internal

thermal overload. If the overload is open, allow time (several

minutes) for overload to reset.

ECM inducer motors do not have an internal overload and are in-

ternally protected through the electronics in the motor controller.

There are four (4) different PSC inducer assemblies to service all

single--stage and 2-stage furnaces with PSC inducers.

Each of the 4 PSC motors have a different horsepower and/or RPM

range required for the various size furnaces.

The motor supplied in the kit for furnaces with PSC inducers is a

2--speed inducer motor. Single--stage operation is achieved through

the use of an adapter harness included with the kit.

There is one (1) kit for modulating furnaces. The replacement

assembly may look different from the assembly installed on the

furnace, but operates the same as the original motor. The new

modulating furnace inducer kit does not require an adapter harness.

See Fig. 1.

Refer to Table 2 for the correct furnace and kit combination.