443 06 2403 01 6/12/2018

NAHA00601WK

INSTALLATION INSTRUCTIONS

TWINNING KIT

Please read these instructions completely before starting the

installation.

SAFETY CONSIDERATIONS

!WARNING

FIRE, EXPLOSION, ELECTRICAL SHOCK AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause carbon monoxide poisoning,

explosion, fire, electrical shock, other conditions, which could

result in personal injury or death. Consult a qualified service

agency, local gas supplier, or your distributor or branch for

information or assistance. The qualified service agency must

use only factory−authorized kits or accessories when

modifying this product.

WARNING

!

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON

MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous

operation, personal injury, death, or property damage.

Furnaces shall NOT be twinned (i.e. tandem or staged

operation) unless approved in factory technical specifications

literature for the furnace. A factory authorized, field−supplied

Twinning Kit MUST be used. Consult furnace pre−sale

literature for specific models approved for twinning and the

correct twinning kit. Twinned furnaces must be installed on

both a common supply AND a common return duct system

as shown in the Twinning Kit Installation Instructions. Only

two furnaces can be twinned on a common supply and

return duct system using a factory authorized twinning kit.

Installing and servicing heating equipment can be hazardous

due to gas and electrical components. Only trained and

qualified personnel should install, repair, or service

heating equipment. Untrained personnel can perform basic

maintenance functions such as cleaning and replacing air

filters. All other operations must be performed by trained

service personnel. When working on heating equipment,

observe precautions in literature, on tags, and on labels

attached to or shipped with unit and other safety precautions

that may apply.

These instructions cover the minimum requirements and

conform to existing national standards and safety codes. In

some instances, these instructions exceed certain local codes

and ordinances, especially those that may not have kept up

with changing residential construction practices. We require

these instructions as a minimum for a safe installation.

Follow all safety codes. In the United States, follow all safety

codes including the current edition of the National Fuel Gas

Code (NFGC) NFPA No. 54/ANSI Z223.1. In Canada, refer to

the current edition of the National Standard of Canada, Natural

Gas and Propane Installation Codes (NSCNGPIC),

CAN/CSA−B149.1 and .2. Wear safety glasses and work

gloves. Have a fire extinguisher available during start−up,

adjustment steps, and service calls.

Recognize safety information. This is the safety−alert symbol

. When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and

CAUTION. These words are used with the safety−alert symbol.

DANGER identifies the most serious hazards which will result

in severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is

used to identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is used

to highlight suggestions which will result in enhanced

installation, reliability, or operation.

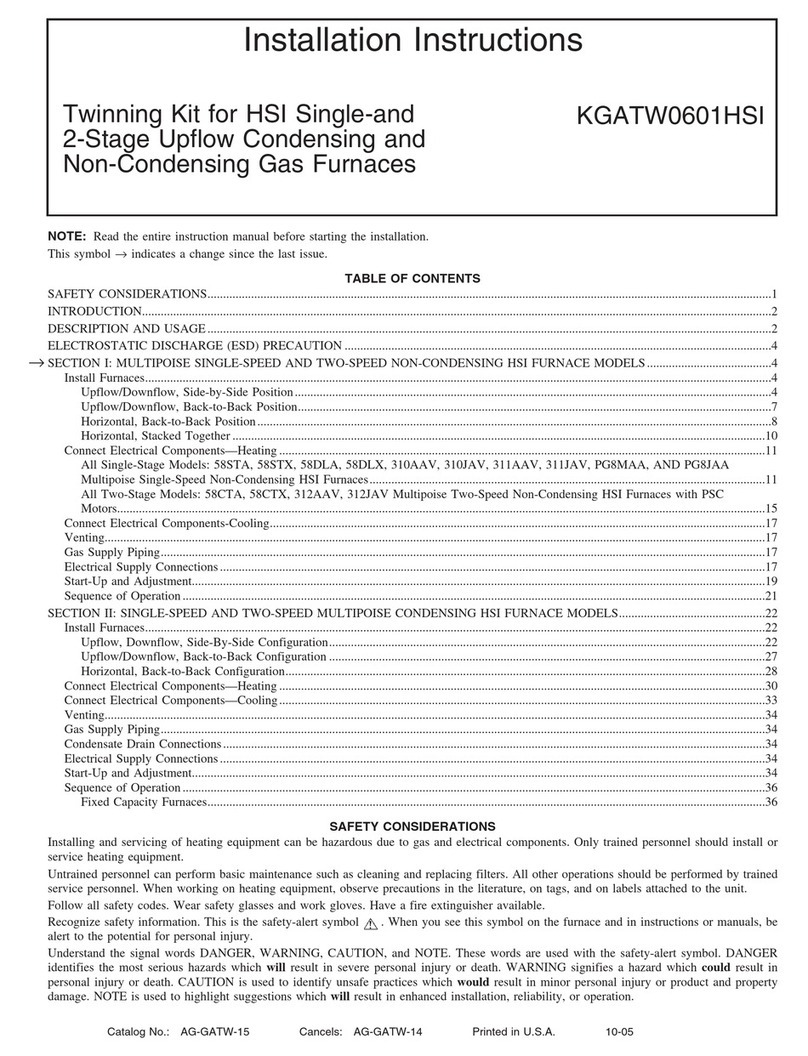

TABLE OF CONTENTS

SAFETY CONSIDERATIONS 1................................

TABLE OF CONTENTS 1.....................................

INTRODUCTION 2..........................................

DESCRIPTION AND USAGE 2................................

ELECTROSTATIC DISCHARGE (ESD) PRECAUTION 4..........

MULTIPOISE SINGLE−SPEED AND TWO−SPEED

NON−CONDENSING HSI FURNACE MODELS 4................

INSTALL FURNACES 5......................................

DIMENSIONS 5.............................................

CONNECT ELECTRICAL COMPONENTS—HEATING 11..........

CONNECT ELECTRICAL COMPONENTS−COOLING 15..........

VENTING 15................................................

GAS SUPPLY PIPING 15......................................

ELECTRICAL SUPPLY CONNECTIONS 15......................

START−UP AND ADJUSTMENT 16.............................

SEQUENCE OF OPERATION 19...............................

!WARNING

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Turn off the gas and electrical supplies to the furnace and

install lockout tag before performing any installation or

modification. Follow the operating instructions on the label

attached to the furnace.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing and gloves

when handling parts.

CAUTION

!