NOTE: Read the entire instruction manual before starting the

installation.

This symbol →indicates a change since the last issue.

TABLE OF CONTENTS

SAFETY CONSIDERATIONS .....................................................1

INTRODUCTION ..........................................................................1

INSTALLATION CONSIDERATIONS .......................................1

Inspect Equipment ....................................................................1

Select Location..........................................................................2

COMPONENT DESCRIPTION ....................................................2

INSTALLATION ...........................................................................3

Mount Unit................................................................................3

Independent System Application..............................................3

Forced-Air Application.............................................................3

Connect Ducts to ERV .............................................................3

Locate and Install Exterior Hoods ...........................................3

Condensate Drain......................................................................4

Wall Control..............................................................................4

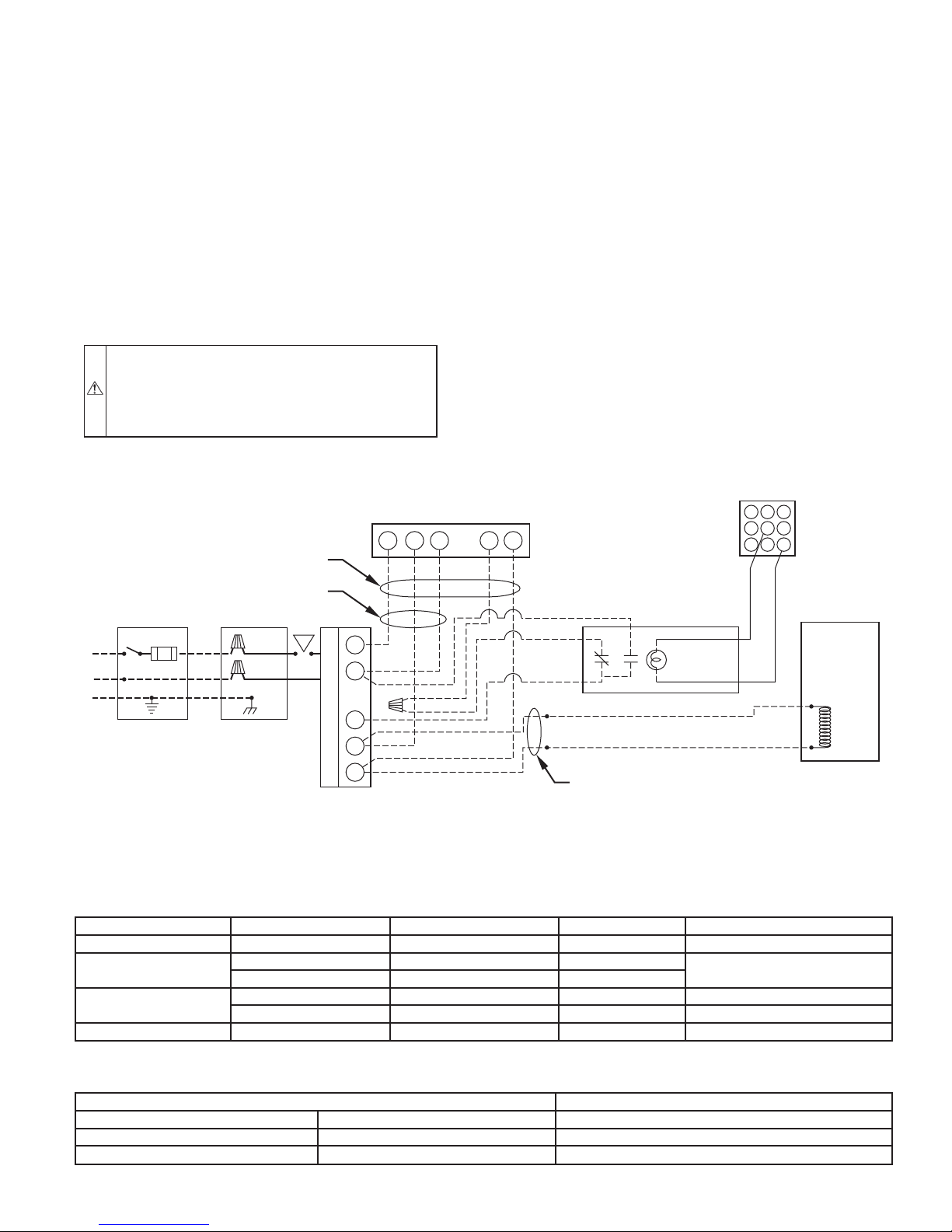

ELECTRICAL CONNECTIONS ..................................................4

115–vac Wiring.........................................................................4

12–vdc Wiring ..........................................................................4

ACCESSORIES..............................................................................4

Interlock Relay..........................................................................4

20 Minute Timer.......................................................................5

60 Minute Adjustable Timer ....................................................5

BALANCING ERV .......................................................................5

Balancing Dampers...................................................................6

Flow Collar ...............................................................................6

CONTROL BOARD OPERATION ..............................................8

Board Function..........................................................................8

Defrost.......................................................................................8

OFF and INTERMITTENT/OFF Mode...................................8

High-Speed Air Exchange ........................................................8

Low-Speed Air Exchange.........................................................9

CARE AND MAINTENANCE.....................................................9

Door.........................................................................................10

Filter ........................................................................................10

Blower Motor and Wheel.......................................................10

Cleaning Core .........................................................................10

TROUBLESHOOTING ...............................................................10

Wall Control............................................................................10

Control Board..........................................................................10

Blower Motor..........................................................................10

Blower Speed Selection..........................................................11

SAFETY CONSIDERATIONS

Installation and servicing of this heating equipment can be

hazardous due to mechanical and electrical components. Only

trained and qualified personnel should install, repair, or service

heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on this

equipment, observe precautions in the literature, on tags, and on

labels attached to or shipped with the unit and other safety

precautions that may apply.

Follow all safety codes. Installation must be in compliance with

local and national building codes. Wear safety glasses and work

gloves. Have a fire extinguisher available during start-up and

adjustment procedures and service calls.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the furnace and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, or CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard that could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in personal injury or product

or property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability or operation.

INTRODUCTION

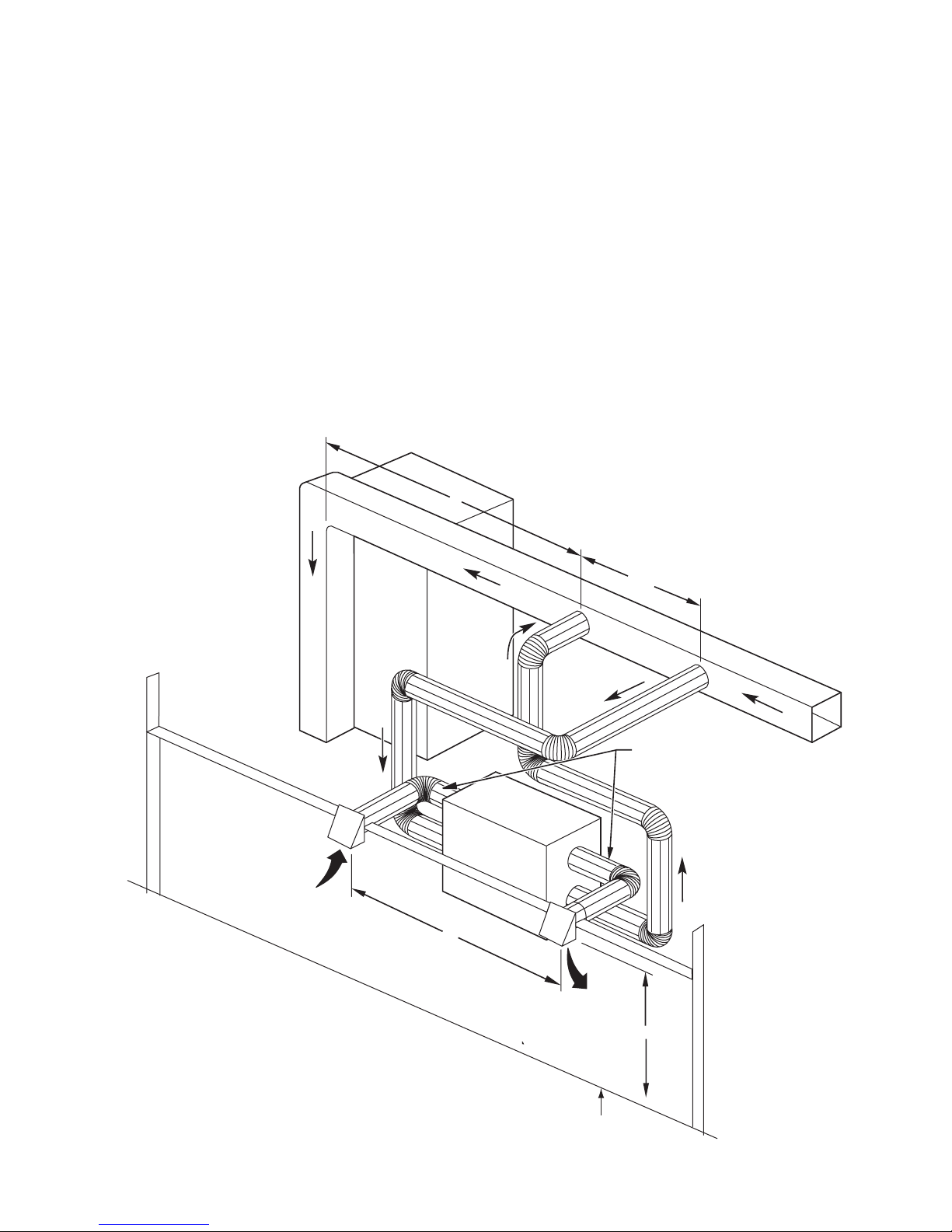

The ERVBBLHU Energy Recovery Ventilator (ERV) is used to

exchange indoor stale air with outside fresh air. The ERV unit is

equipped with a special energy recovery core which transfers both

sensible and latent heat with the fresh incoming air. The cross-flow

design core allows entering and leaving air streams to transfer heat

energy without mixing (See Fig. 14).

The model ERVBBLHU is available in 2 sizes with airflow ranges

of 64–152 CFM, and 117–214 CFM. The design of this unit is

horizontal. Special attention should be given to duct application,

balancing the ERV, and locating unit for easy access and routine

maintenance.

INSTALLATION CONSIDERATIONS

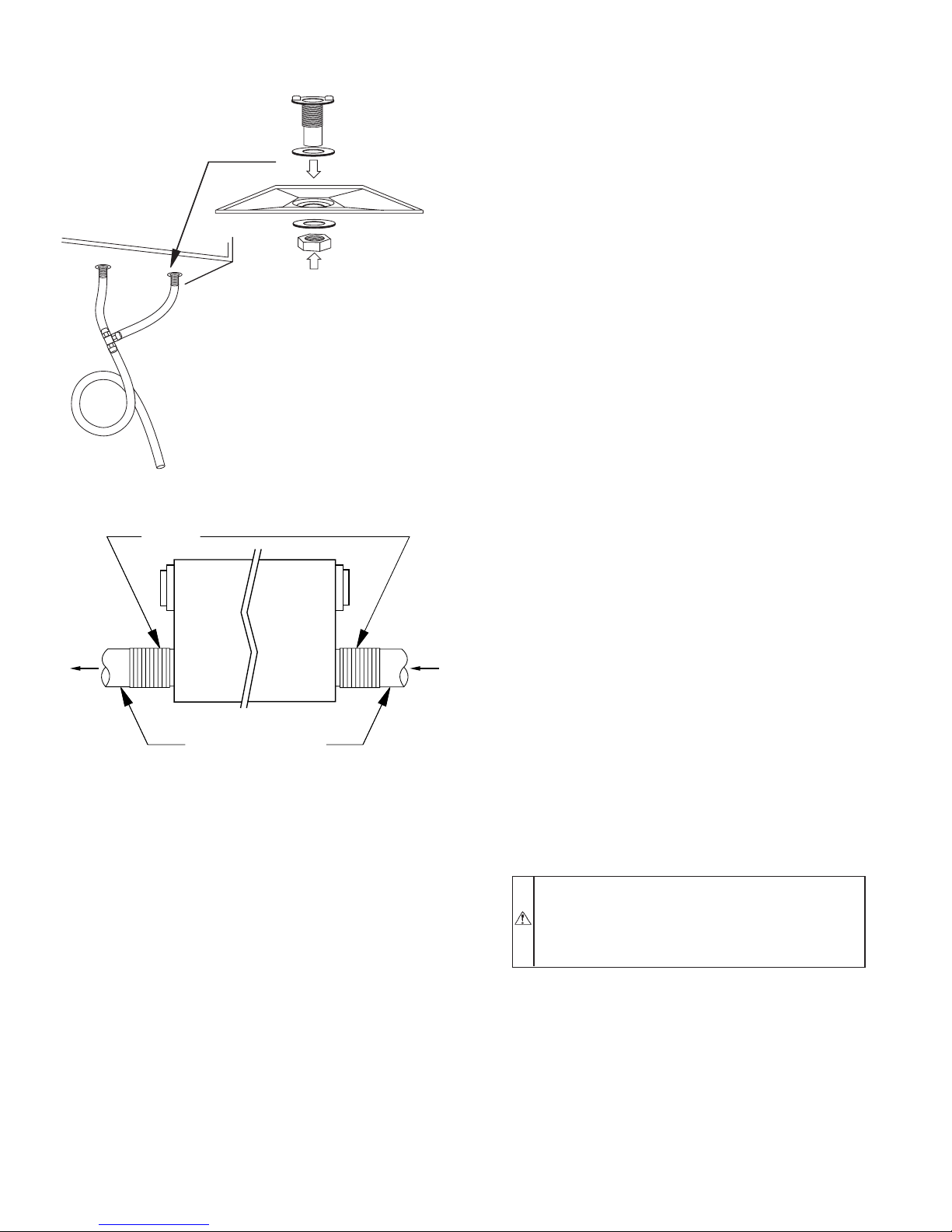

I. INSPECT EQUIPMENT

Move carton to final installation location. Remove ERVBBLHU

from carton taking care not to damage unit. Remove all packaging

and inspect unit for damage. Remove parts bag from inside unit.

File claim with shipping company if shipment is damaged or

incomplete. Check to make sure ERV unit matches Fig. 2.

Fig. 1–ERVBBLHU Energy Recovery Ventilator

A00092

Installation, Start-Up, and

Operating Instructions

ERVBBLHU

ENERGY RECOVERY VENTILATOR

Cancels: II ERV-64–2 II ERV-64–3

4–05

—1—