13 Actuator General Information

13.1 Actuators are fitted to the 12mm A/F square shaft on the Transfer Drive (TD) box.

13.2 Check that the actuator, thermal fuses (where present) and wires are undamaged.

13.3 Check the actuator label to for correct voltage and operation as below:

•24V AC/DC OR 230V AC

•Spring Closed OR Spring Open

•With thermal fuse (TF) or without thermal fuse (NTF).

14 Instructions for fitting Thermal Fuse (TF)

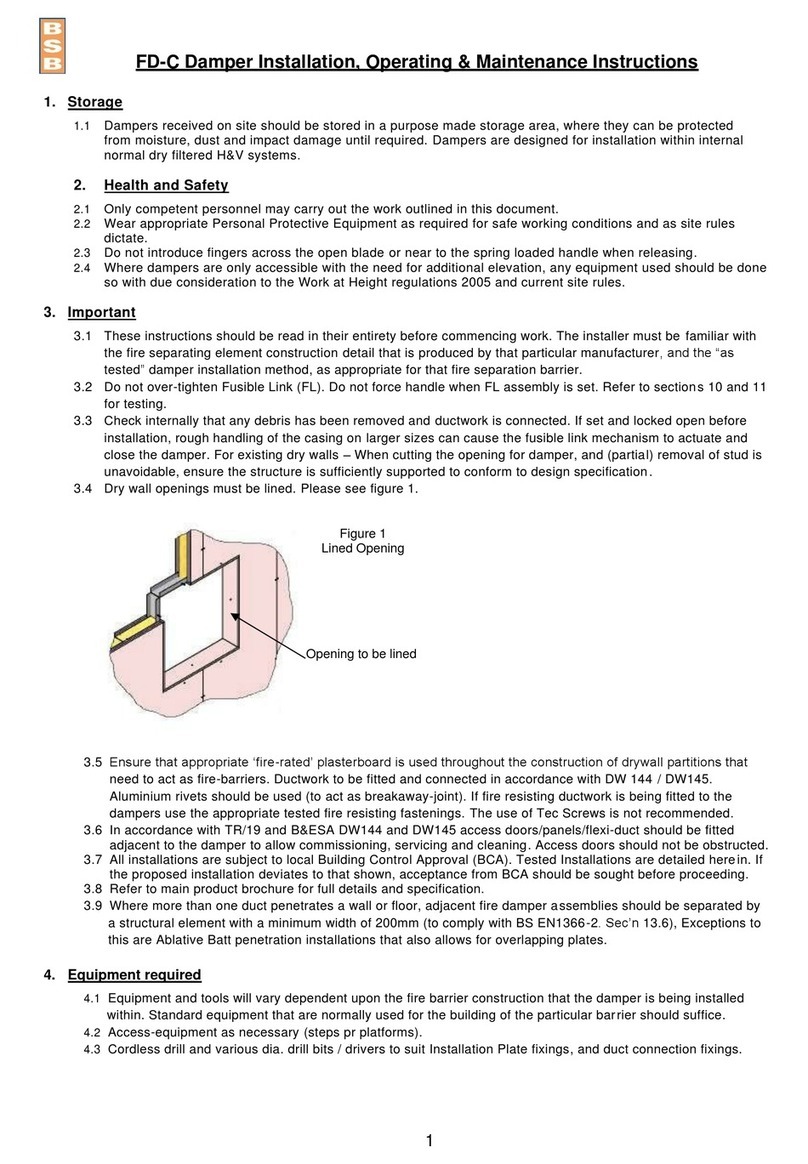

14.1 For dampers fitted with TF actuators - Fix self-adhesive TF template (supplied)

onto the duct. This should typically be above the actuator. For round ducts, the

three drilled holes must be in-line with the duct axis. (For ductless installations, a

TF bracket is available from BSB and can be fixed to the damper casing).

14.2 Drill holes in duct (sizes/positions are detailed on template label –see fig. 13).

Remove burrs.

14.3 Fit the TF to the duct with the two screws provided using Philips №2

screwdriver/bit.

15 Instructions for Fitting the FSD-TD actuator (fail-safe closed) –Fig. 1

15.1 Actuators are normally factory fitted, but optionally may be assembled on site.

15.2 When fitting the actuator for the first time, check the actuator voltage is correct

and the required motor spring-return travel direction is known. Refer to the

actuator label for spring/drive directions.

15.3 Ensure actuator is in ‘released’ state by inserting crank handle (provided) as

shown on label and ‘unlocking’ the mechanism. Then, manually wind and lock the

actuator with the crank handle, 1.5 turns only to relieve the pre-set tension.

15.4 Damper must be in closed position

15.5 Fit actuator cradle in desired orientation and then slide actuator into position. Fit

indication pointer, large washer and 8mm A/F screw (all provided) and tighten to

5Nm max torque

16 Instructions for Fitting the SEVAC actuator (fail-safe Open) –ref fig. 1

16.1 Actuators are normally factory fitted, but optionally may be assembled on site.

16.2 When fitting the actuator for the first time, check the actuator voltage is correct

and the required motor spring-return travel direction is known. Refer to the

actuator label for spring/drive directions.

16.3 Manually wind the actuator, using the crank handle (provided) fully to the ‘reset’

position, and lock into position. (Due care should be taken to stop winding

when slight resistance is encountered –over-winding can result in

permanent damage to the damper/actuator which may invalidate the

warranty)

16.4 Damper must be in closed position

16.5 Fit actuator cradle in desired orientation and then slide actuator into position. Fit

indication pointer, large washer and 8mm A/F screw (all provided) and tighten to

5Nm max torque

17 Instruction for mechanically testing Damper/Actuator assembly

17.1 Test manually using the crank handle provided. (Due care should be taken to stop

winding when slight resistance is encountered –over-winding can result in

permanent damage to the damper/actuator which may invalidate the warranty).

Check damper blades move to same position as the actuator is indication. Ensure

fail-safe position of damper blades.

18 Instructions for Wiring the FSD-TD actuator

18.1 Terminate wires within a junction box (supplied by others) compliant with site rules

and Electrical Installation Regulations (BS7671) in close proximity to actuator,

also referring to wiring diagram on actuator label.

18.2 As a pre-check BEFORE power is established, the actuator should be wound

manually using the crank handle provided. (Due care should be taken to stop

winding when slight resistance is encountered –over-winding can result in

permanent damage to the damper/actuator which may invalidate the

warranty)

18.3 Test the unit (see section 20)

19 Removing/replacing or repositioning the FSD-TD actuator –Fig. 1

19.1 Ensure that the power has been isolated from the actuator and that the damper is

now in the failsafe position, this would normally be with the blades in the closed

position.

19.2 Using the 8mm spanner, undo the centre-bolt anti-clockwise and remove along

with the washer keeping safe and close to hand.

19.3 Lift the actuator and cradle and place in a safe secure place within the limitations

of the attached wiring. Ensure that the actuator is not supported/left hanging solely

by the connected wiring.

19.4 For repositioning, turn cradle through 90° to the desired position, and then

relocated actuator, pointer, washer 8mm A/F screw into position and tighten to

5Nm max torque.