Introduction

What is a fire damper and why might they be needed?

The SD-C Series Single Blade Circular ire Damper is designed to

stop the spread of fire through ducts passing through walls and

floors.

The product range has many features and options to meet the

requirements of specifiers, contractors, local and national authorities.

Dampers are available to suit both low/medium and high velocity

applications.

What are the ‘E’ and ‘ES’ classifications?

To achieve the classifications to EN13501-3, fire dampers and fire

and smoke dampers shall be tested to EN1366-2 and a 300Pa

pressure difference is applied across the damper. During the fire

test period, the integrity of the seal between the damper and the

structure shall not have any gaps larger than 150mm x 6mm. There

shall not be any sustained flaming. The largest size of damper to be

manufactured for sale as a single section shall be fire tested.

E = Integrity

The maximum leakage permissible at 300Pa corrected to 20°C is

360m3/hr/m2(100 l/s/m2) throughout the fire test period.

ES = Integrity with Smoke Leakage Performance

The maximum leakage permissible at 300Pa corrected to 20°C is

200m3/hr/m2(55.5 l/s/m2) at ambient prior to the fire test and

throughout the fire test period. In addition, for the ES classification to

be attained, the smallest damper must also meet the 200m3/hr/m2

maximum leakage with a 300Pa pressure across the damper. (This is

equivalent to just 0.55 l/s on a 100x100 damper)

ire dampers should be installed as tested.

Some applications (fan off) allow the use of tests undertaken to BS

476-20/22 and this is also allowed worldwide in areas outside of the

EU. Test reports showing testing to EN 1366-2 should be acceptable

to meet the requirements of BS 476-20/22, but the reverse is

definitely not the case and no classifications are available.

However, as a word of caution, in whichever case, the correct model

must be selected, to match fire resistance time with installation

method and with the supporting construction (wall or floor).

To ensure that all testing and assessments are traceable back to

initial fire test reports, the BSB SD-C series is product certificated by

the Loss Prevention Certification Board (LPCB). This means that in

addition to normal BS EN ISO 9001 compliance, the product is also

checked to ensure that same product is being manufactured that has

been tested or assessed.

BSB have a policy of continued testing and product certification to try

and provide as broad a number of installation methods as possible.

BSB also follow regulation and standards development very carefully

to provide input on changes and to be able to pass on relevant

information to designers, specifiers, building control authorities

(BCA's) and installers.

Introduction

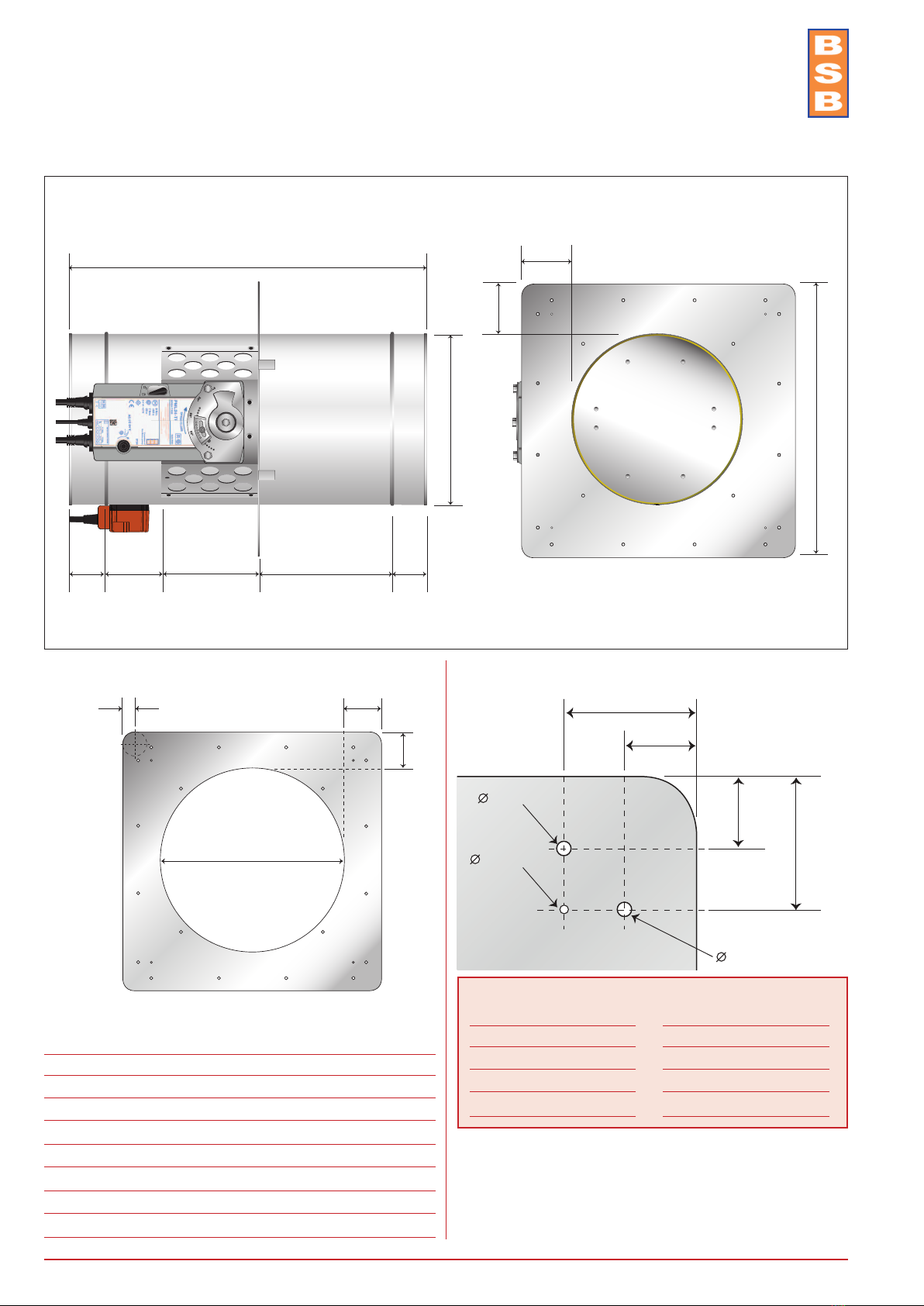

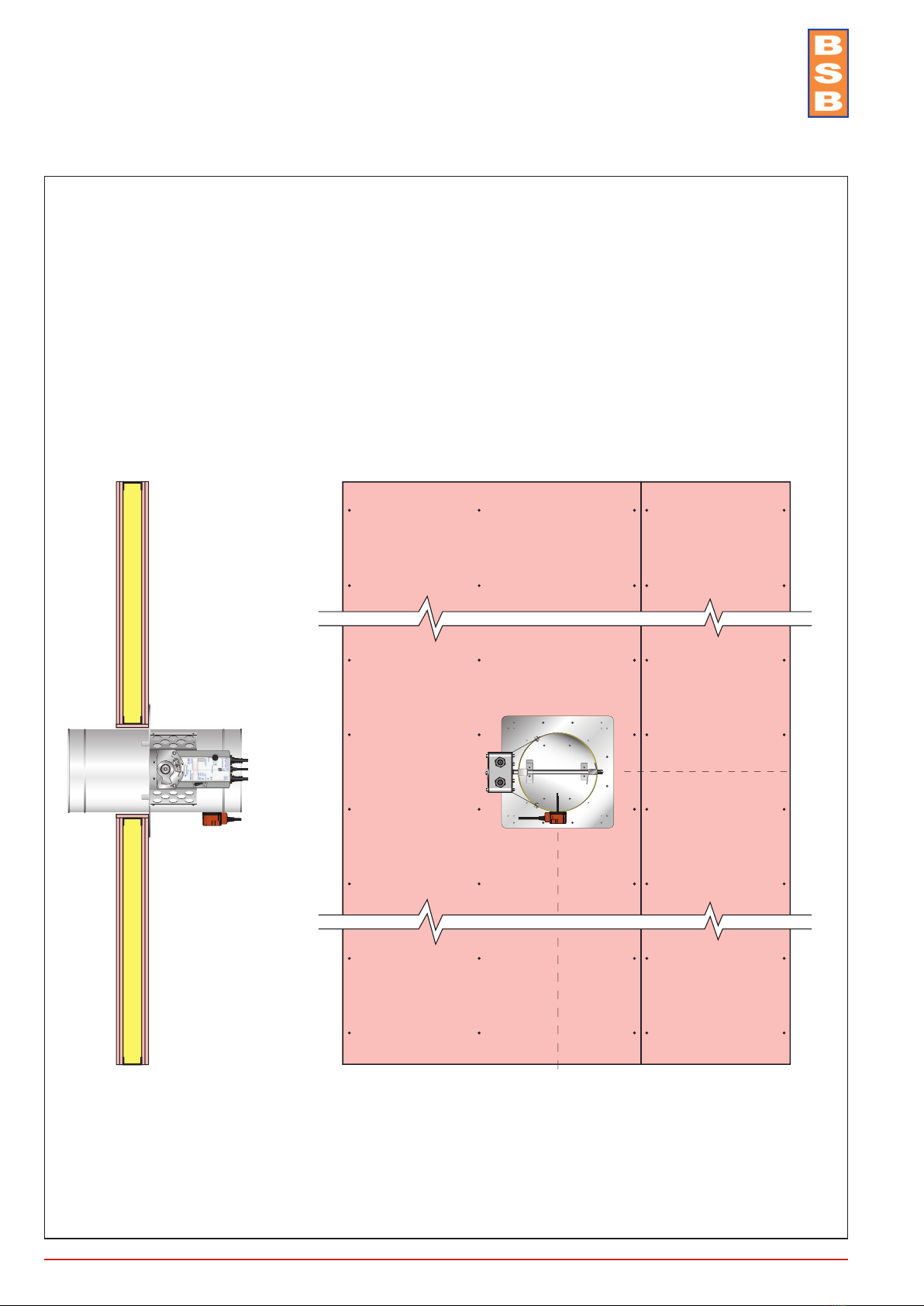

The SD-C Motorised ailsafe Single Blade combination ire

and Smoke Damper has been designed specifically for

installations where space is at a premium and installation within

the fire separation is not feasible.

The SD-C Single Blade ire/Smoke Damper provides greater

free area than comparable sized conventional multi blade

fire/smoke dampers.

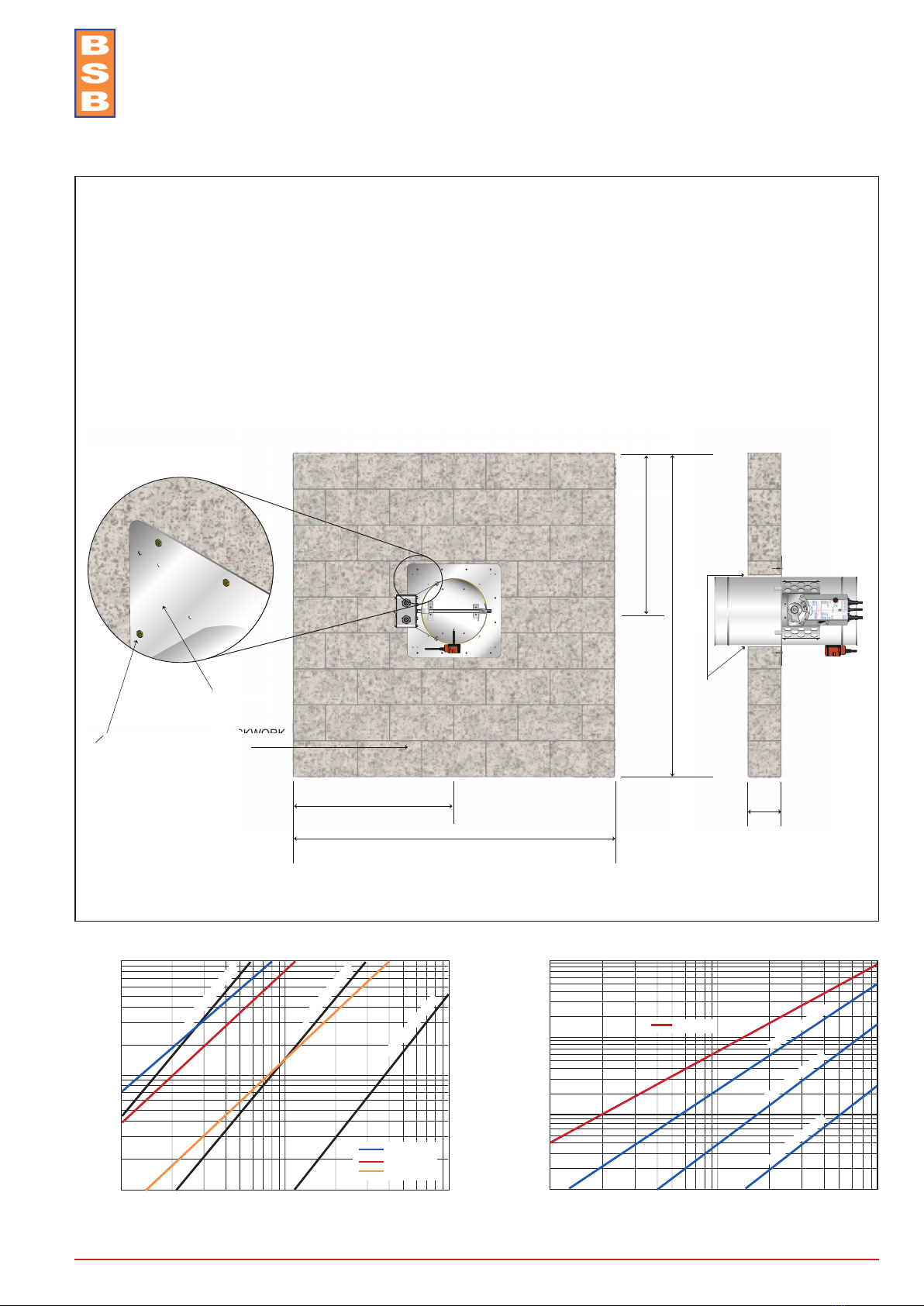

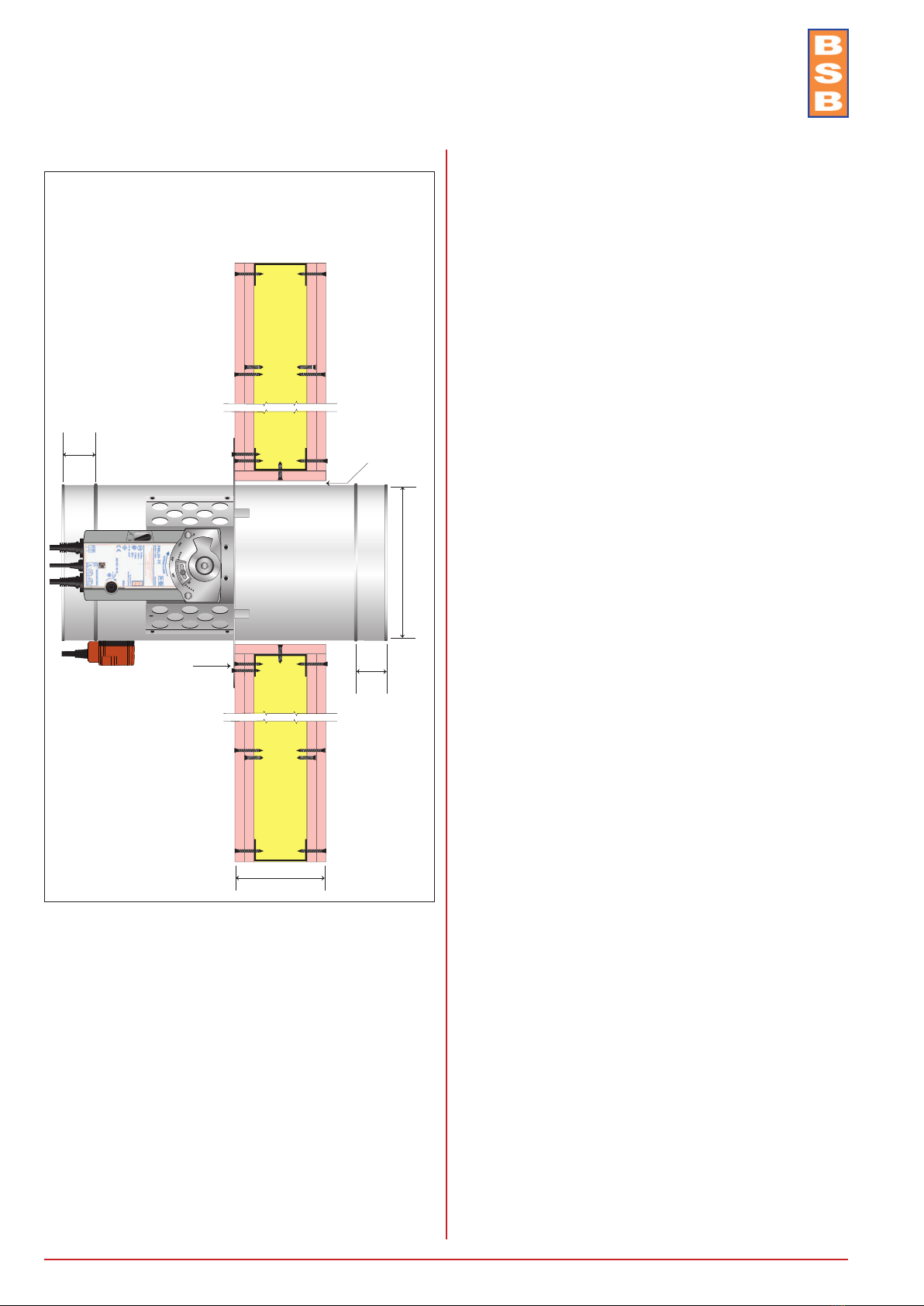

The installation plate, with its engineered installation

perforations, acts as a template to allow the marking of the fixing

positions on the surface structure to which the plate will be

affixed, allowing for a quick and efficient install.

Testing and Conformities

Tested to EN1366-2. See installation details for full details.

Damper casings conform to BS EN 1506

Tested/assessed and achieved equivalent classification to:

ES Classification (BS EN 1366-2/BS EN 13501-3)

•BSB SD-C fitted with Installation Plate

E180 - Blockwork/Masonry wall

ES120 - Blockwork/Masonry wall

ES90 - Concrete floor

ES120 - Horizontal application

(please refer to BSB sales office)

ES90 - Horizontal application

(please refer to BSB sales office)

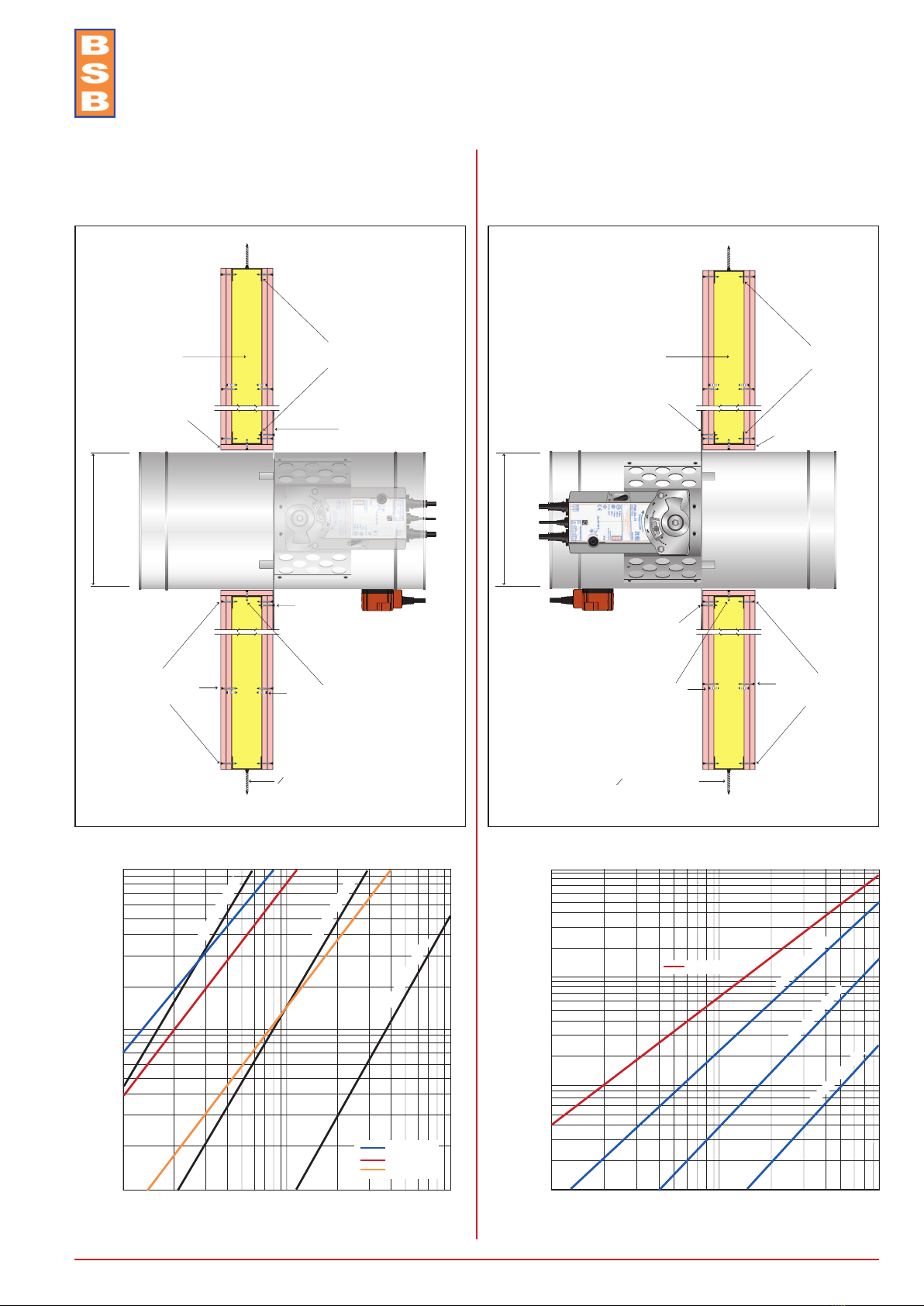

E120 - Dry Partition wall

ES120 - Dry Partition wall

Integrity only (BS 476-20/22 - ADB)

Meets the requirements of BS 476-20/22 -

Refer to BS 476-10.6.6.3

SD-C Blade leakage (BS EN 1751)

•Class 2

Corrosion Testing

BBA test report 50447 issue 2 refers

•Tested to BS EN 60068-2-11:1999

SD-C Series

Single Blade Combination ire and Smoke Dampers – Introduction

www.bsb-dampers.co.uk

2

SD-C eatures and Benefits

•Tested and certified installation variants of the SD-C are

available for both blockwork and stud partitions.

•All BSB tested installation methods give at least a E90

classification.

•Unique blade construction.

•Halogen free LS cable

•Exceeds the requirements of EN1366-2

•Reduced commissioning time

•Thermal fuse replaceable external to the duct.

•Test switch integral to the thermal fuse allowing the damper

to be tested locally and individually.

•LED indication that power is available to the actuator and the

thermal fuse is intact.

•Installation plate with template location holes to allow easy

installation.