03

1

2

3

4

6

7

8

9

18

17

16

15

15

14

13

13

12

11

10

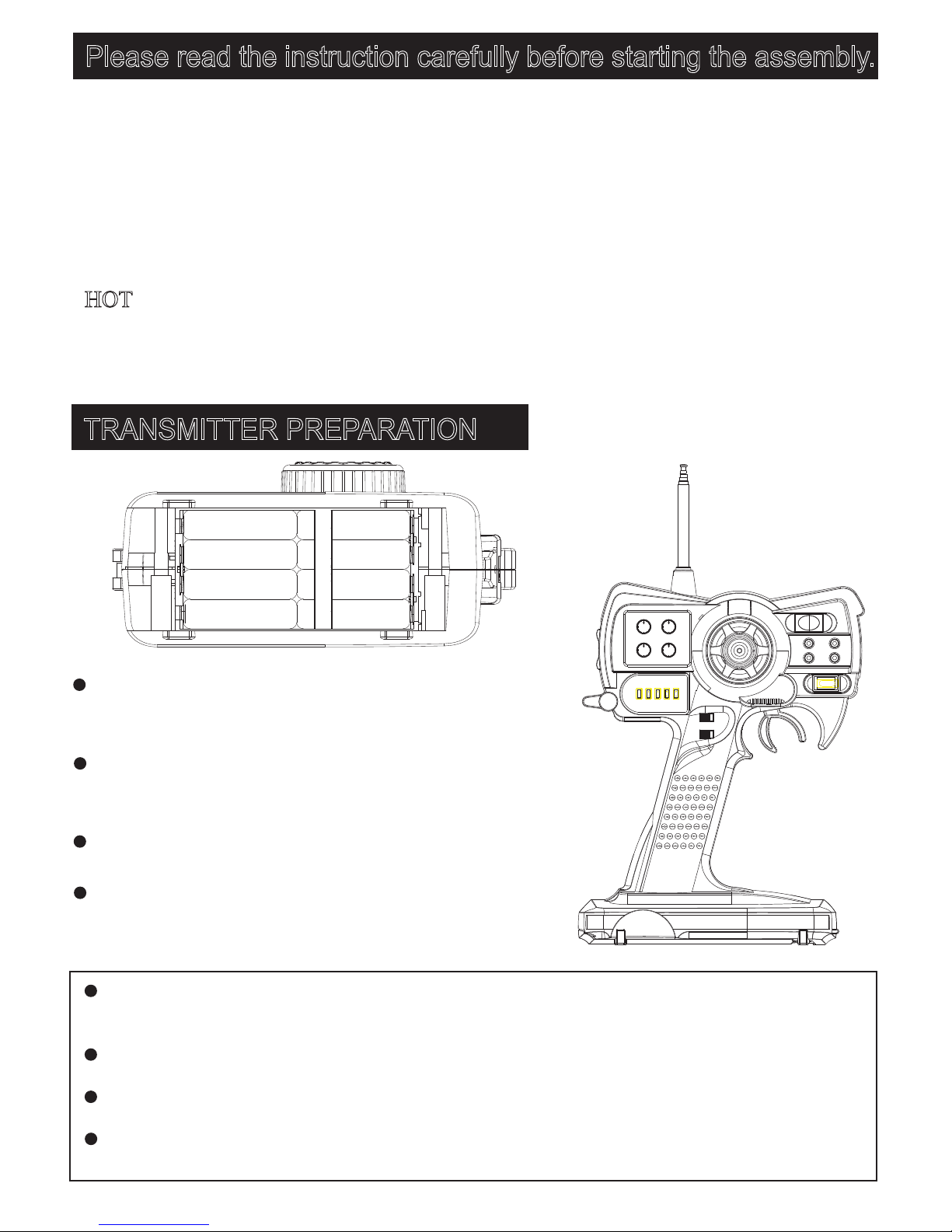

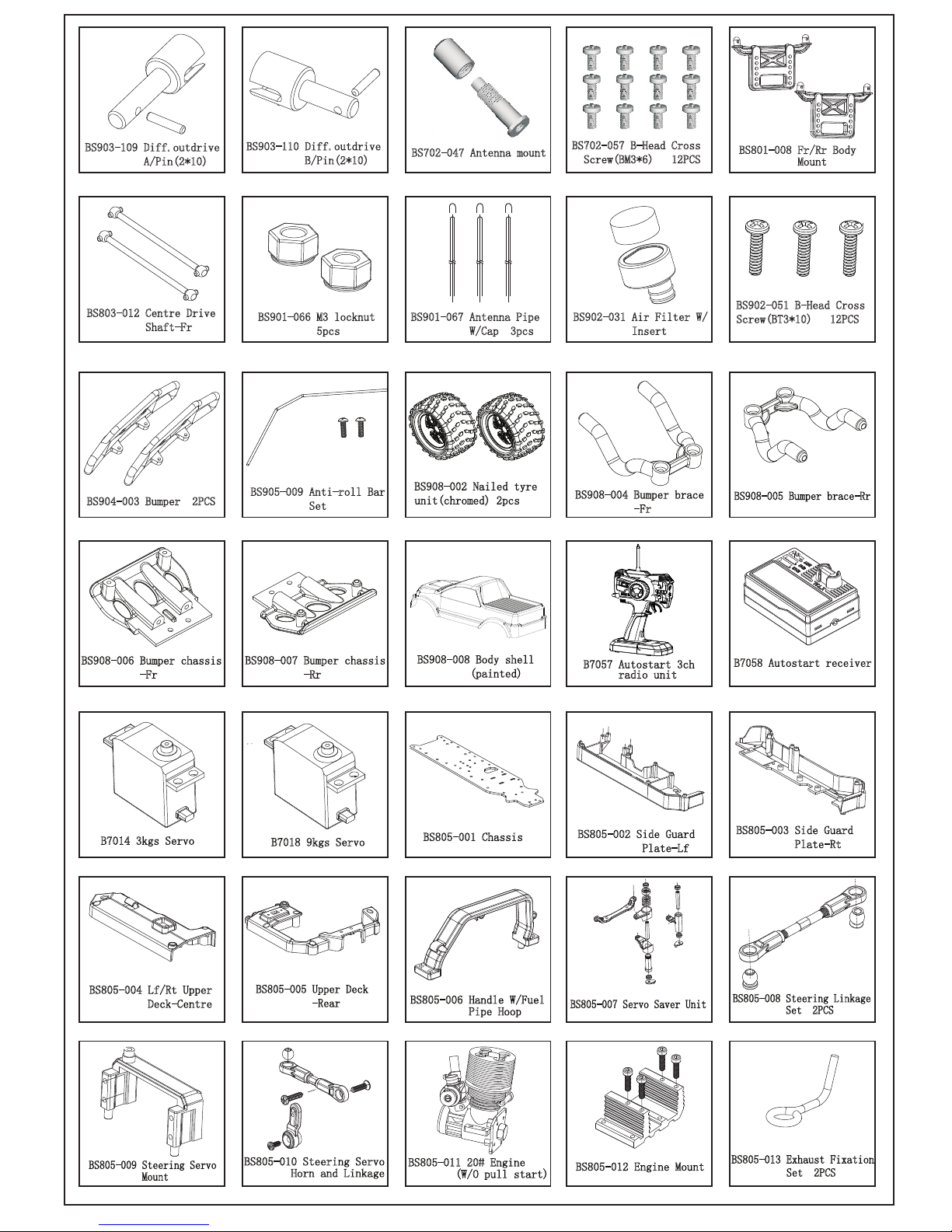

Install the receiver antenna.

Install the transmitter antenna.

Loading the battery on the transmitter.

Install the charged battery on the truck.

GLOSSARY OF TRANSMITTER

BEFORE THE OPERATING

Antenna: The transmitter antenna should be pulled

out completely before turning on the power switch.

Power switch: Pushing up the switch to turn on the t

ransmitter, and pressing it down to switch off. Before

driving the truck, always turn on the transmitter first,

then the receiver, and when finishing driving, always

turn off the receiver first, then the transmitter.

Power LED: These indicators are showing the power

and signal sending strength. When the battery runs

low, the indicators will be off one by one. When the

battery voltage is lower than 8.5v, low voltage indicator

flashes. Please change batteries immediately.

Wrist wrap hole: This is for installing wrist wrap,

which makes it easier to take the transmitter.

Battery charging port: When Ni-Mh batteries or Ni-CD

batteries are used, you can charge with this port.

Throttle trigger: The throttle trigger is used to control

forward, and braking.

Steering wheel: This is for controlling the left and right steering of the racing model.

3 channel power switch: Also as Autostart switch. This Autostart switch ignites the engine when it is

pressed for less than 5 seconds.

Steering D/R trim: Tune counterclockwise to reduce the steering servo angle, and clockwise to

increase the steering servo angle.

Throttle D/R trim: Tune counterclockwise to reduce the throttle, and clockwise to increase the throttle.

Steering neutral trim: Tune counterclockwise to adjust the steering to left, and clockwise to adjust the

steering to right.

Throttle neutral trim: Tune counterclockwise to adjust the throttle forward, and clockwise to adjust the

throttle backward.

Steering reverse-direction switch: Left slide the switch, then the steering wheel turns clockwise and

thesteering servo turns right direction. Right slide the switch, so the steering wheel turns

counterclockwise and the steering servo turns left direction.

Throttle reverse-direction switch: Left slide the switch, push aside the throttle trigger, then the throttle

servo turns clockwise. Right slide the switch, push aside the throttle trigger, then the throttle servo

turns counterclockwise.

Crystal cover: crystals of different frequencies can be changed here.

Throttle trigger trim: Use a flat screwdriver to tighten/loosen the screw to achieve desired throttle

trigger position.

Battery cover: Slide the cover panel to open it (With OPEN indicator on the panel); to close it, insert

thecover to the concave, then push the cover to seal it.

Battery case: Install eight (8) “AA” batteries (or rechargeable batteries) into the battery case setting

well the right polarity. When not in use, the batteries shall be taken out. When the power indicator

is weak, change the batteries.

1

3

45

6

7

8

9

10

2

11 12

14

1817

16