Snap Hook / Carabiner Inspection:

Ensure locking device and keeper / gate operates freely and smoothly and that keeper / gate closes and remains closed and locked

until intentionally opened.

Inspect to ensure component is free of cracks, distortion, corrosion, or nicks.

Ensure keeper / gate is not bent, is free of burrs, not packed with snow or ice, and is clean and functioning properly.

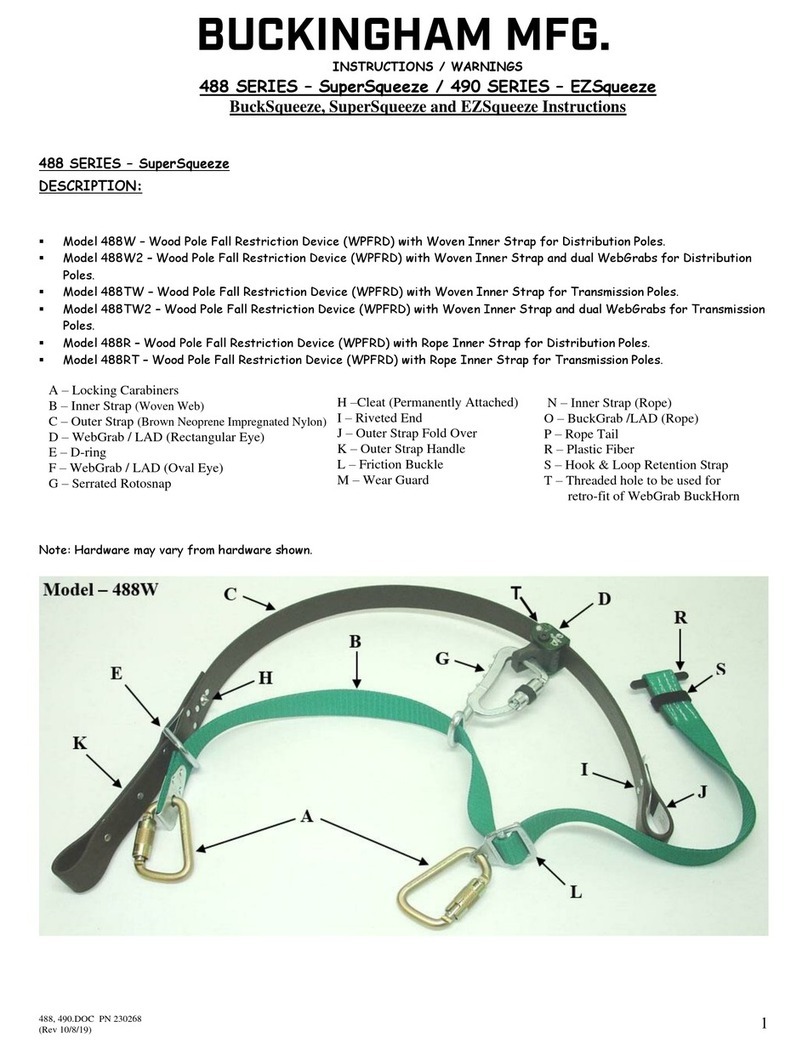

Length Adjusting Device (LAD) Inspection:

Unit is free of cracks –(usually depicted by fine jagged lines) and extensive

wear or corrosion to cam, or housing.

Lanyard is properly installed into LAD, snap end of lanyard exits the LAD

next to release tab (Fig. 3).

Proper operation of mechanism by pivoting release lever back and forth.

Movement should be unrestricted with no binding. Binding could be caused

by burrs, packed snow, or ice.

NOTE: Also, read and follow other instructions, warnings, and inspection

guidelines enclosed with this product.

If any evidence of wear or deterioration as outlined above is observed, immediately cease use, destroy the product, and replace it with

new equipment. Should any unusual conditions not outlined above be observed, or you have reasonable doubt about a particular

condition, remove the equipment from service and notify your Supervisor, Safety Director, or contact Buckingham Mfg. Co. for

clarification. Failure to carefully and completely inspect your equipment could result in serious injury or death.

Warnings:

Know the job and the regulations governing performance requirements and select the proper equipment.

Read carefully, understand, and heed these and all other included instructions, warnings, and cautions before using this equipment.

Failure to do so could result in your serious injury or death. Should questions arise concerning the proper use or condition of your

equipment, contact Buckingham Manufacturing Co. at 1-800-937-2825.

All affixed labels should be left in place and all instructional material kept for future reference.

This equipment is intended for use by properly trained professionals only.

This product is designed to be used by a person with a maximum weight of 350 lbs. when fully equipped.

For personal use only. NOT for towing or hoisting.

Fall protection equipment, (i.e. fall arrest, work positioning belts, climbers, retrieval, suspension etc.) should not be resold or

provided to others for re-use after use by original user as assurance cannot be granted that a used product meets criteria of applicable

standards and is safe for use to a subsequent user.

Be certain this equipment is suitable for the intended use and work environment. It should only be used as personal protection

equipment (PPE). If suitability for intended use is in doubt, consult a safety engineer or contact Buckingham Mfg. before using.

Destroy any and all equipment subjected to impact loading.

Always attach each snap hook / carabiner of the Adjustable Positioning Lanyard to the proper D-ring of the body belt.

Do not attach work positioning snap hooks / carabiner to accessory rings. Accessory rings are intended for attachment of a belt

supporter only. Note: Belt supporters are intended to distribute belt weight of users who carry an unusually heavy load of tools. Belt

supporters are not intended to support the weight of the user.

As outlined by OSHA 1926.502 (e)(2) positioning devices shall be secured to an anchorage capable of supporting at least twice the

potential impact load of an employee's fall or 3,000 lbf. (13.3 kN), whichever is greater.

Product is manufactured to meet the following standards / regulations as they are applicable:

ASTM F887 / OSHA 1926.959 / CA. OSHA 2940.6.

The Adjustable Positioning Lanyard is only one component / element of a positioning system outlined by ASTM F887.

Avoid contact of this equipment with sharp edged or pointed tools, high temperature surfaces, welding or other heat sources.

(Be aware of the lanyards position / placement on the pole or tree at all times in relation to the operations being performed. Use

extreme caution when performing operations such as cutting, drilling, sawing, etc. Always perform this type of work well above the

lanyard to avoid the potential of tool contact with the lanyard, causing damage which may result in a fall, serious injury or death).

Guard against debris which could block the action of the cam (pebbles, twigs, ice, snow, etc.).

If ice or snow buildup is noted, run the adjusting device along the length of the rope to remove the build-up and ensure the adjusting

device is clean and free of packed snow or ice.

Only Buckingham Mfg. Co., or those authorized in writing by Buckingham Mfg. Co., may make repairs to this equipment.

Remove from service if subjected to impact loading. Even though no visible signs are present, internal damage may have occurred

thus reducing its strength and margin of safety.

This product is intended for work positioning only.

Buck Easy-Just Doc (REV. 12/30/16) 2 of 4

P/N 230341

Tab

Lever