RETRACTINST.Doc P/N 230159 9-11-98 (Rev. 6-7-18)

INSPECTION

•Inspect the entire assembly prior to each use as outlined in ANSI Z359.14-14. The inspection should include, but not be limited to,

inspecting for any sign of excessive wear, damage, malfunction, cracked housing, absence or illegibility of markings. If any evidence of

wear or deterioration as outlined in this document is observed, immediately cease use, destroy the product, and replace it with new

equipment. Should any unusual conditions not outlined be observed, or you have reasonable doubt about a particular condition,

remove the equipment from service and notify your Supervisor, Safety Director, or contact Buckingham Mfg. for clarification (1-800-

937-2825).

•An additional inspection shall be performed by a competent person, other than the user, at an interval of no more than one year.

•The frequency of periodic inspection by a competent person shall be established by the user’s organization based on careful

consideration of relevant factors. Such factors include, the nature and severity of workplace conditions affecting the equipment and

the modes of use and exposure time of the equipment.

•An inspection recording chart has been provided at the end of these instructions for your convenience.

•Before each use, test the locking mechanism of the retractor by steadily and sharply jerking on the webbing at varying intervals and

over its full length, making sure the mechanism locks. Maintain the locked position and then release the tension, making sure all the

webbing retracts back into the retractor housing. Do not use a device if it does not lock or retract.

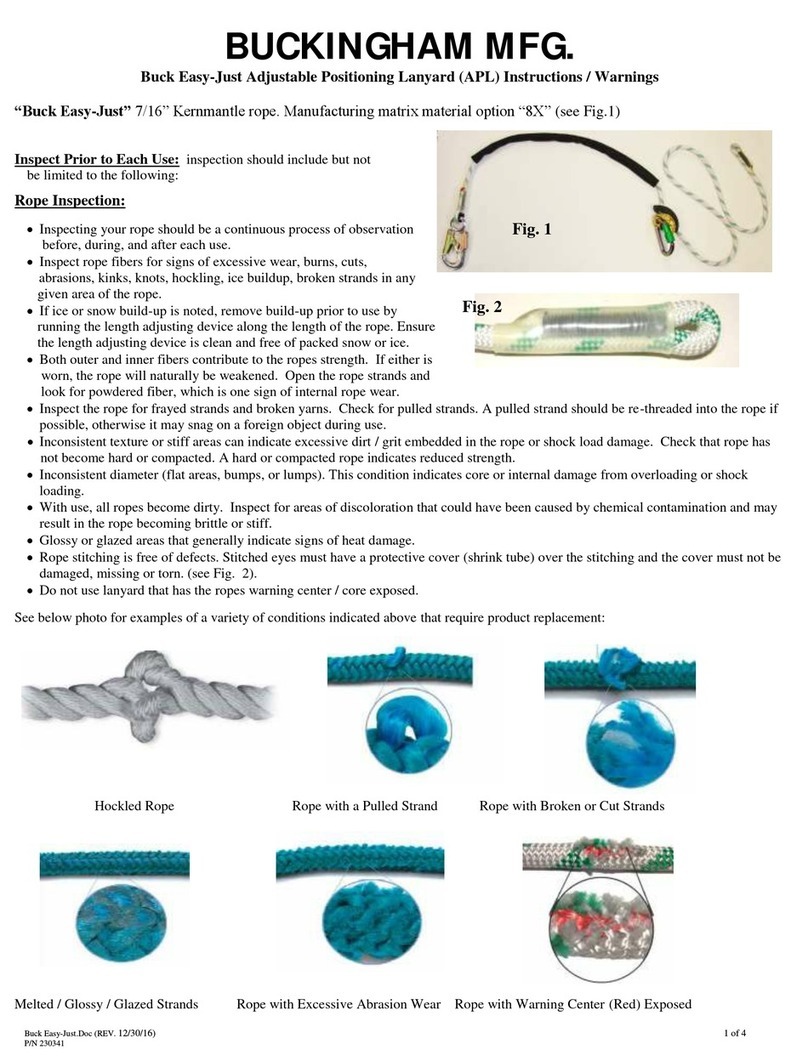

•Before each use, pull out the entire length of webbing and inspect for any defects such as cuts, kinks, knots, abrasions, burns, broken

fibers, chemical or physical exposures, cracks, charring, excessive wear, discoloration, swelling, loose, cut, or missing stitching (fig. 7).

Do not use a device that exhibits any defects such as those noted.

•Inspect all hardware for correct function and to ensure against cracks, distortion, corrosion, nicks, or excessive wear. Also, ensure that

locking mechanisms and gates are not bent, are free of burrs, clean and are working freely and smoothly. Snaphook rivets should be

checked to ensure that cracks and broken, loose, or bent connections do not exist. If any of the mentioned issues exist, do not use the

product, and tag it out of service.

•Ensure that the webbing of the unit retracts evenly into the unit housing and without any twists.

•Before each use, inspect to ensure the breakaway jacket of energy absorbing pack (if included), has no broken stitches, tears, stretch

marks, or other evidence of impact loading.

•Before each use, inspect that the impact load indicator has NOT been activated. If visible, remove product from service.

•If using the 5008 series with the Self - Retracting Lanyard Bracket Assembly, check the nuts of the bracket assembly for tightness

before each use. The four small nuts (10-32 threads) used for the attachment bracket should be tightened such that the bolts ends are

even with the tops of the nyloc inserts of the nuts. NOTE: It is recommended that nyloc nuts as a minimum, be replaced after being

twice removed. The large (½” Centerlock) nut should be tightened until the bolt end is protruding approximately 1/8” from the top of the

nut. Once tightened ensure that the U-bracket freely rotates. If the U-bracket does not rotate, back the nut off slightly until the U-

bracket will freely rotate.

NOTE: Centerlock nuts are not reusable. Discard and replace a centerlock nut once removed.

•The 6005, 6007, 6008, and D6008 series devices equipped with a swivel must be mounted to the attachment points in a way to avoid any

exposure of the swivel to transverse or bending loads. This is EXTREMELY important in the case of a fall.

•Remove from service, destroy, and discard unit if it does not pass the aforementioned inspection criteria and replace immediately.

CARE AND MAINTENANCE

•Units are factory sealed, therefore, do not attempt to dismantle for any purpose.

•Do not lubricate these units.

•Keep unit free of dirt, chemicals, or any other exposures that might render it inoperable or unsafe.

•Web material can be cleaned with a mild detergent (i.e. Dawn). Allow to air dry away from heat or direct sunlight. Never clean webbing

with thinners or similar products.

•Lubricate lock mechanism and gate on both sides of snap hook or carabiner at least weekly or as often as required to maintain smooth

operation (no binding) with light weight lubricant such as WD-40®.

STORAGE

•Always store unit in a clean dry area away from heat or direct sunlight.

•Do not store near corrosive chemicals, dusty environments, oils, solvents, or at extreme temperatures.

•Store in an open area and allow to air dry if exposed to water.

WARNINGS

•This equipment is intended for use by properly trained professionals only.

•Anyone with a history of back or neck problems that may be aggravated or complicated by using this equipment should not do so.

•Pregnant women and minors must not use this equipment.

•Users of this equipment must be in good health and not under the influence of drugs or alcohol.

•Fall protection equipment, (i.e. fall arrest, work positioning belts, retrieval, suspension etc.) should not be resold or provided to others

for re-use after use by original user as assurance cannot be granted that a used product meets criteria of applicable

standards and is safe for use to a subsequent user.

•Selection of products should be such that they aid the worker in the performance of their job and particular work situation.

Therefore, be certain this equipment is suitable for the intended use and work environment. It should only be used as

personal protection equipment (PPE). If suitability for intended use is questionable, always consult your supervisor, safety

director, or contact Buckingham Mfg. at 1-800-937-2825 before using. Never use in violation of any applicable company,

state, or federal requirement or standard (fig. 1).

•Manufacturer’s instructions shall be provided to the end user. Completely read, understand, and follow these and all other

related instructions, warnings, and guidelines pertaining to this and all associated equipment before use. Failure to do so could result

in your serious injury or death (fig. 2).

•Correct installation, use, and maintenance of this product is essential to its performance and reliability.

•Never connect these SRL / PFL units to more than one person, as they are specifically designed as one person devices.