General power tools safety warnings

Working area

Keep working area clean and well lit. Untidy and dark areas can lead to accidents.

Do not operate power tools in potentially explosive surroundings, for example, in the

presence of inflammable liquids, gases or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep children and bystanders at a distance when operating a power tool. Distractions can

cause you to lose control of it.

Electrical safety

Always check that the power supplycorresponds to the voltage on the rating

plate.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

Personal safety

Use safety equipment. Always wear eye protection. Using safety equipment such as a

dust mask, non-skid safety shoes, a hard hat, or hearing protection whenever it is needed

will reduce the risk of personal injury.

Avoid accidental starts. Ensure the switch is in the off position before inserting the plug.

Carrying power tools with your finger on the switch or plugging in power tools when the

switch is in the on position makes accidents more likely.

Service

Your power tool should be serviced by a qualified specialist using only standard spare parts. This

will ensure that it meets the required safety standards.

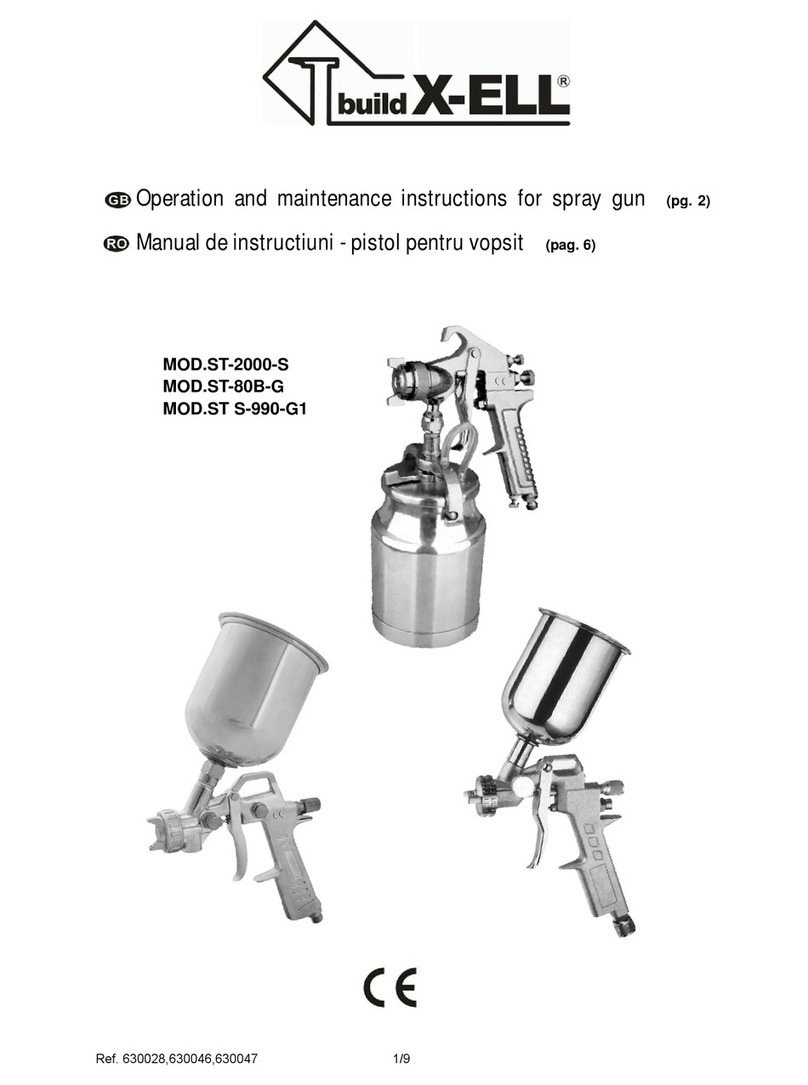

Specific safety instructions for electric spray gun

Always use protective glasses and mask

Never spray paint to others or animals nearby . Do not let the paint in contact with skin.

Do not smoke or work near fire or other flammable substances.

Always make sure that there is adequate ventilation when performing painting operation

Do not use spray gun if you have dirty hands with grease, oil , solvent as you can lose

control of the tool.

Keep spray gun cleaner . After each use of the power tool clean tank and nozzle. Do not use

washing flammable spray gun whose flash point exceeds 32 ° C.

Always before dilute the paint, read carrefully the instructions manual.

Application

Electric gun is used for spraying liquid substances on various surfaces. Airless result from

spreading by pumping at high pressure through the nozzle orifice vortex..

IT IS NOT DESIGNED FOR PROFFESIONAL USE.