manual-rmp210-rmp3545-en-18 Page 5 / 16

Short instructions

Commissioning:

Remove the packaging and inspect the machine for transport damage.

Read the instructions thoroughly and observe all safety instructions.

Lift the machine off the pallet using a forklift. Afterwards the RMP can be rolled to your place of in-

stallation.

RMP3545: Have your plant electrician connect the RMP3545 to 400V, 3-phase, 50Hz.

Operating:

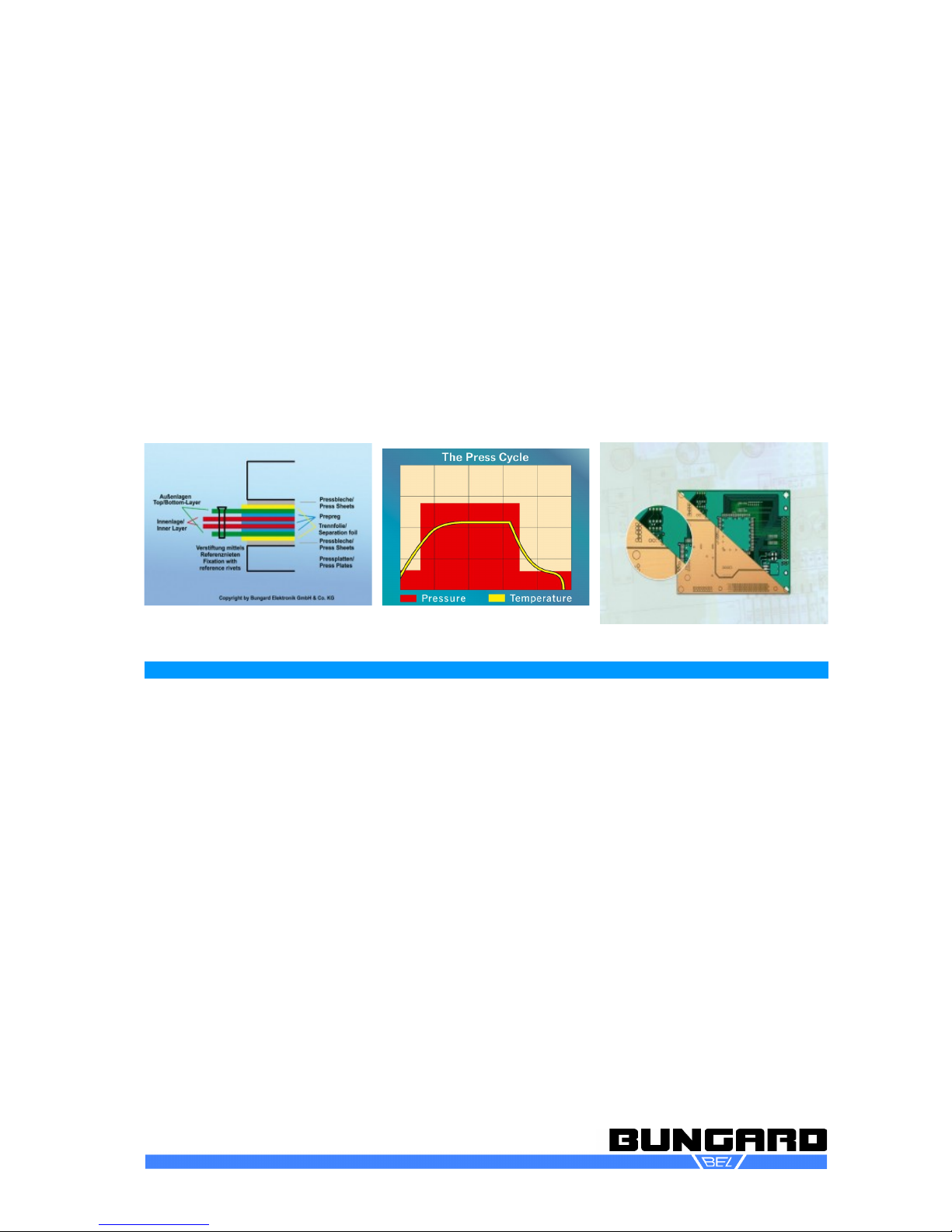

Place the press plates in the press

chamber for a functional test.

Switch on the power switch (MAINS

also serves as emergency stop, right

in the control panel). The compressor

starts.

Switch on the pressure by pressing

PRESSURE (compressor might re-

start).

On the hand wheel at the bottom left,

set the desired pressing pressure.

This depends on the material type,

age of the prepregs and most import-

ant: the size of your press pack. For an overview, see Printing Preferences. For material from the

RMP starter set with a press package size of 250 x 350mm (RMP210) set as standard 12 bar (for

the RMP3545 and press package size 350x450 is 8 bar).

Set the desired pressing time at the timer. After pressing PROG, the hour digits flash. With + or –

you can change the value. If you press PROG again, the minutes digits flash, then the seconds di-

gits flash. After the 4th press of PROG the normal display reappears and you can start the press

cycle by pressing - (Start / Stop). For material from the RMP Starter Set, the default time is 90

minutes (1:30:00).

Only after the pressing cycle is started, the temperature controls light up. The green display value

corresponds to the current heating-up specification (TARGET TEMPERATURE). The upper, red

value represents the currently reached temperature (CURRENT TEMPERATURE). To change the

preset temperature: Press MODE and then the arrow keys to set the desired heating temperature,

for example to 155 ° C as shown in this figure. Then press the button (MODE) again to save the se-

lected value. Heating starts with a pre-set ramp of 6 ° C / minute. After the set time has elapsed, the

heating will switch off and the fans will automatically switch off to cool down.

If you set higher temperatures than 175 ° C, you have to switch on the additional fans manually at

the beginning of the pressing cycle, so that the environment of the heating plates does not overheat.

Let the press stack cool sufficiently before removing it or wear appropriate protective gloves.