Page 5 / 6

The thermostat has a soft heat-up function

that prevents over-temperature. After each

initial start the lower display will show in-

creasing temperature values until the set

value is reached. Temperature setting pro-

posals are about 175 °C for normal and

fresh prepregs. You must determine the

best setting for your application. If the tem-

perature is too low or heating time too

short, the laminate will have delamination

problems or air-bubbles inside. Both will

damage the multilayer board.

Work Flow:

Operation details are related to prepregs

and inner layers specifications. As a matter

of fact, these settings may change depend-

ing on the type of prepregs.

a) If you do not prefer to swim press (this is

possible for 3- 4 layer board) fix your lay-

ers with reference pins or rivets. We re-

commend to have the reference pins out-

side of the press plates and to include

the reference marks in your film layouts

for all layers

b) protect your press plates with tedlar foil

or something alike to prevent the press

plates from sticking to your pcb. Select

suitable material to avoid fire and result-

ing severe economic losses.

c) Insert PCB stack into press plates

d) Select appropriate temperature and pres-

sure to avoid burning your pcb and emer-

ging of poisonous gas.

e) pressure is adjusted according to board

specification. For boards 210 x 300mm²:

approx. 12 bar

f) heater temperature is selected (accord-

ing to condition and type of prepregs nor-

mal range: 155 - 175°C)

g) heater is activated

h) heating-up procedure and press se-

uence at preset temperature (normally

60-120 minutes. Time depending on tem-

perature preset and on room temperat-

ure according to condition / type of

prepregs)

i) cooling down under pressure to 50° C or

lower (about 30 -45min) to avoid skin

burns. If you want to take out stack at a

higher temperature wear suitable protect-

ive gloves.

j) Never take out stack at a temperature

higher than 100°C. Danger of delamina-

tion.

k) PCB stack is taken out of the machine.

l) boards are depinned.

The se uence will take all at all approx. 3

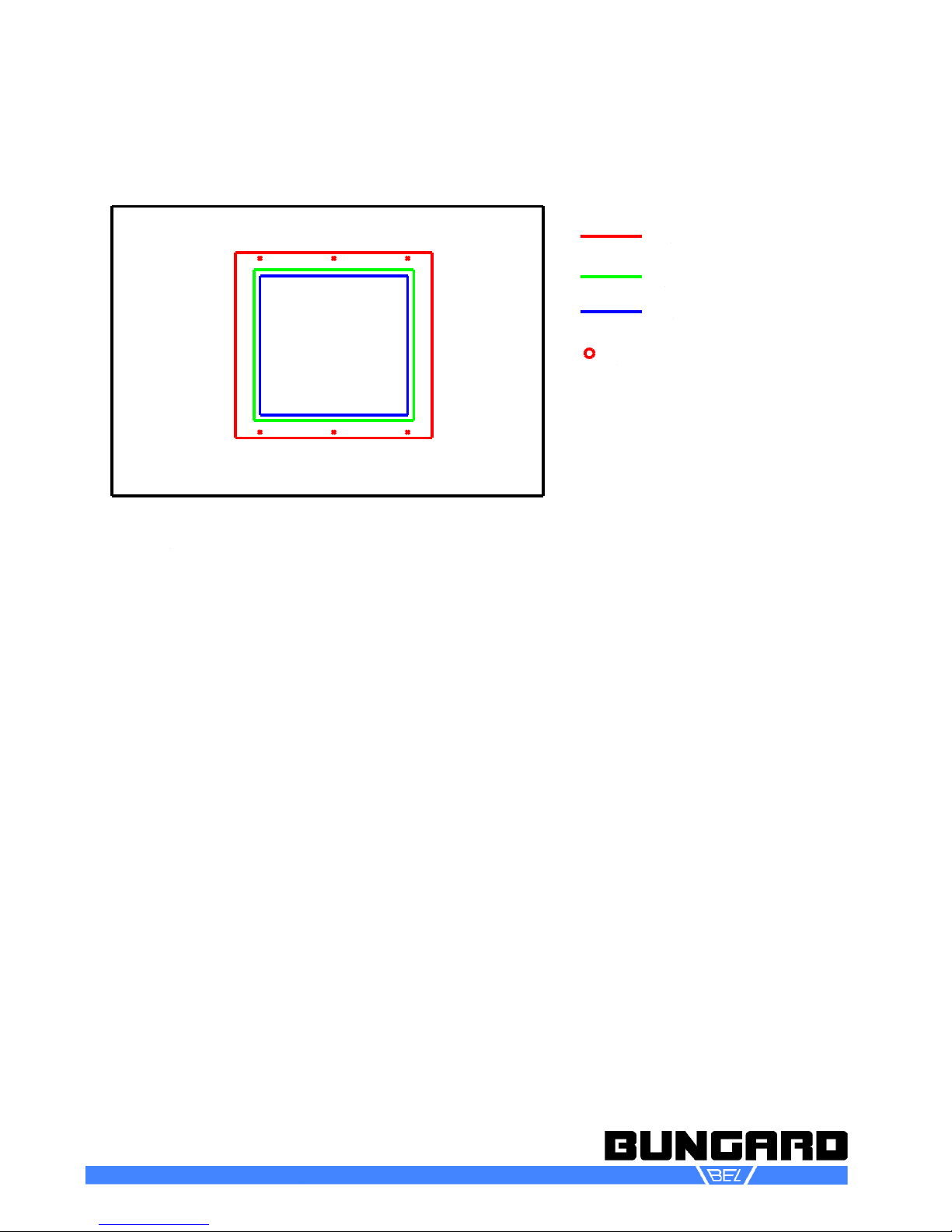

hours. Gross size of the PCB is 250 x 350

mm which will result in PCB net size of 210

x 300 mm². Depending on the material you

use, the rim of your multilayer will show less

resin as in the middle and needs to be cut

off (normally 1-2 cm on each side. In the

meantime board supplier improved their

products so this effect may not occur at all)

Process time will decrease down to half an

hour if you take out stack at a temperature

of about 100°C. But this is made on the op-

erators responsibility and we will deny any

liability for this.

RMP 210

Multilayerpress

Instructions for Use