Index

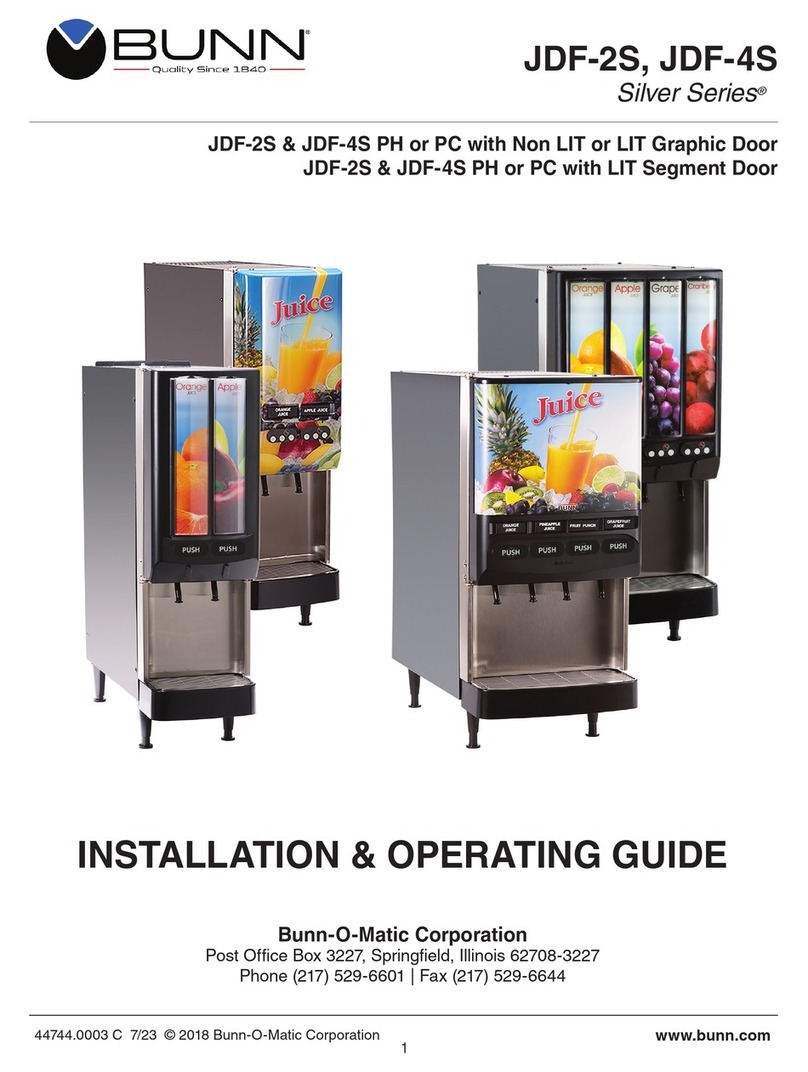

Unit 1: Installation

Site Requirements .............................................................................................................. 4

Location of the Serial Number .......................................................................................... 4

Prepping Machine for Install ............................................................................................. 4

Hopper Assembly ............................................................................................................... 5

Electrical Install ..................................................................................................................5

PowderAutoll(PAF)Installation(Optional) ................................................................... 6

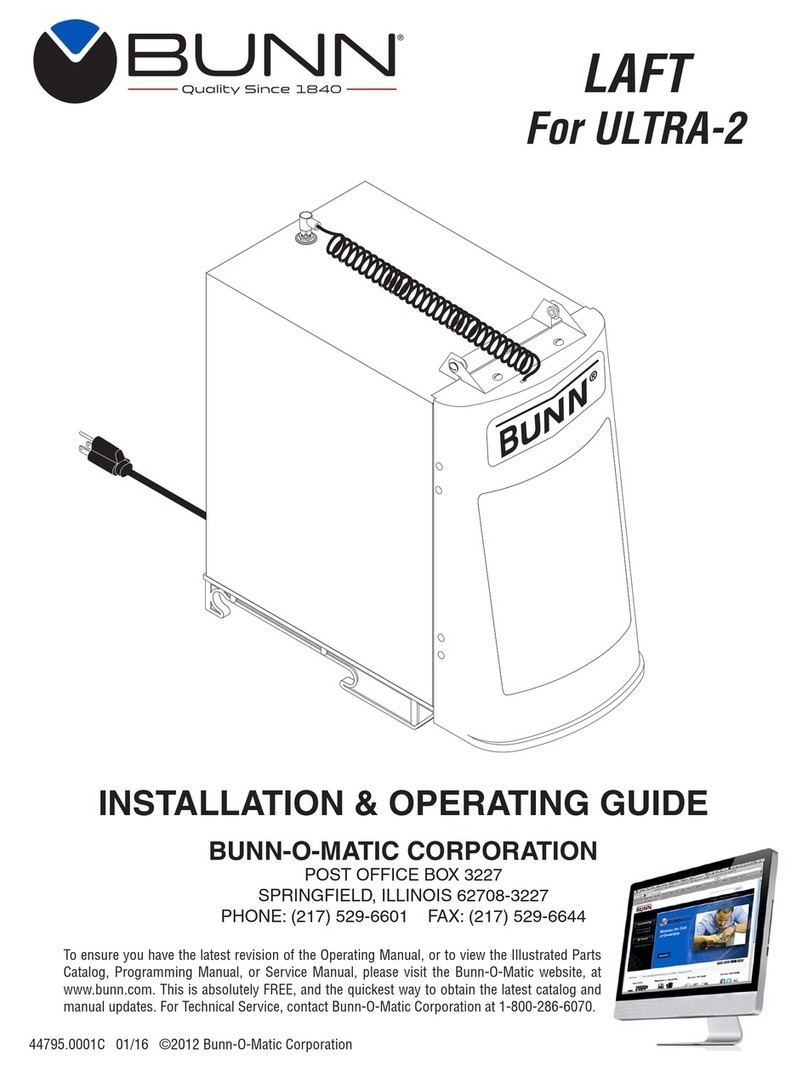

LiquidAutoll(LAF)Installation(Optional) ..................................................................... 7

Unit 2: Setup

User Interface...................................................................................................................... 13

SwitchOperation(OperatingControls) ..................................................................... 13

SwitchOperation(ProgrammingControls)............................................................... 13

Setup.................................................................................................................................... 14

Setup Machine.............................................................................................................. 14

Product Preparation..................................................................................................... 17

PAF-PowderMixSet-Up(BrixRatio) ......................................................................... 17

LAF–LiquidConcentrateSet-Up(BrixRatio) .......................................................... 18

ULTRA1and2StartUpwithLAF............................................................................... 19

Unit3:MachineComposition

ExteriorOverview ...............................................................................................................21

RemovingtheEnclosure ................................................................................................... 21

MachineFunctionandOperations.................................................................................... 24

TICBoard(TimeInaCan) ........................................................................................... 24

MainControlBoard...................................................................................................... 24

Mechanical System ...................................................................................................... 24

Refrigeration System ................................................................................................... 24

Temperature Sensing System..................................................................................... 25

Torque Sensing .............................................................................................................. 25

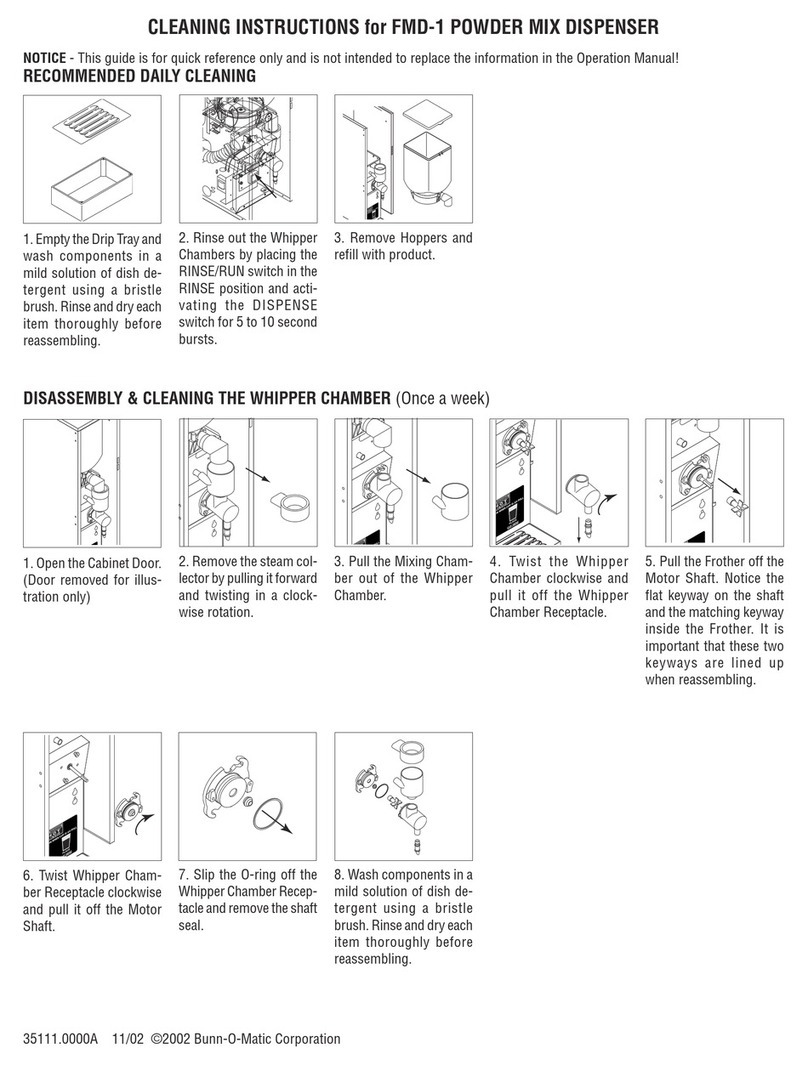

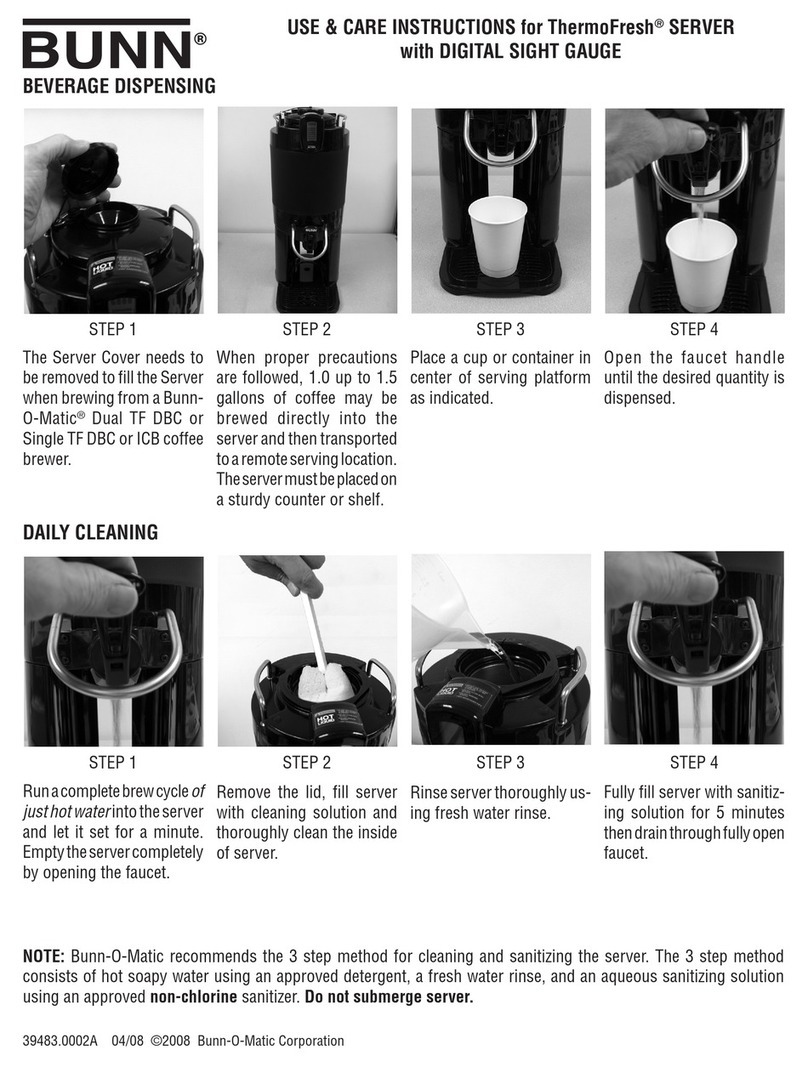

Unit4:PreventiveMaintenance

Tools Required....................................................................................................................27

PM Parts ..............................................................................................................................27

PriortoservicingtheULTRA............................................................................................. 27

PreventiveMaintenanceInstructions ............................................................................... 27

Unit 5: Troubleshooting

Test Menus .......................................................................................................................... 30

Test Augers ......................................................................................................................... 30

RellThreshold(UltrawithLAFKitInstalled) ................................................................. 30

Temp and Torque Screen...................................................................................................31

Warning Messages ............................................................................................................. 31

Error Messages................................................................................................................... 33

ProductDoesNotFreezeorFormIceCrystals ............................................................... 34

TorqueSensorBoard ......................................................................................................... 35

Thermistor........................................................................................................................... 35

UltraPAFErrorMessages ................................................................................................. 36

Triac Maps ........................................................................................................................... 36

© 2010 Bunn-O-Matic Corporation. All Rights Reserved

Rev. A