8 TRI-FLEX II BED - OPERATION MANUAL

Important Safety Information

MATTRESS INFORMATION

•Since1999theHospitalBedStandardIEC60601-2-38(1996;1999)requirestheheight

of the top edge of the side rail be at least 220mm or 22 cm (9”) above the mattress with

out compression.

•Themattressintendedforusewiththisbedis18cm(7”)thick.Useofamattress

taller than 18cm (7”) will not be in compliance with the UL-60601-1 / IEC 60601-2-38

(1996;1999)ratingofthebed.Atallermattressreducesthedistancebetweenthetopof

the side rail and the top of the mattress. Serious injury or equipment damage may occur

if the patient goes over the top of the raised side rails.

•TomaximizethefullscopeofUL60601-1/IEC60601-2-38(1996;1999),thisbedis

intendedforpatientuseinONLYthe122cm(48”)or137cm(54”)widthcongurations.

Within the current standard, patient and caregivers are safely removed from pinch points

andmovingcomponentswhichcouldcauseharm.Congurationsotherthandescribed

reduce the distance to these points which could result in severe personal injury or

equipment damage.

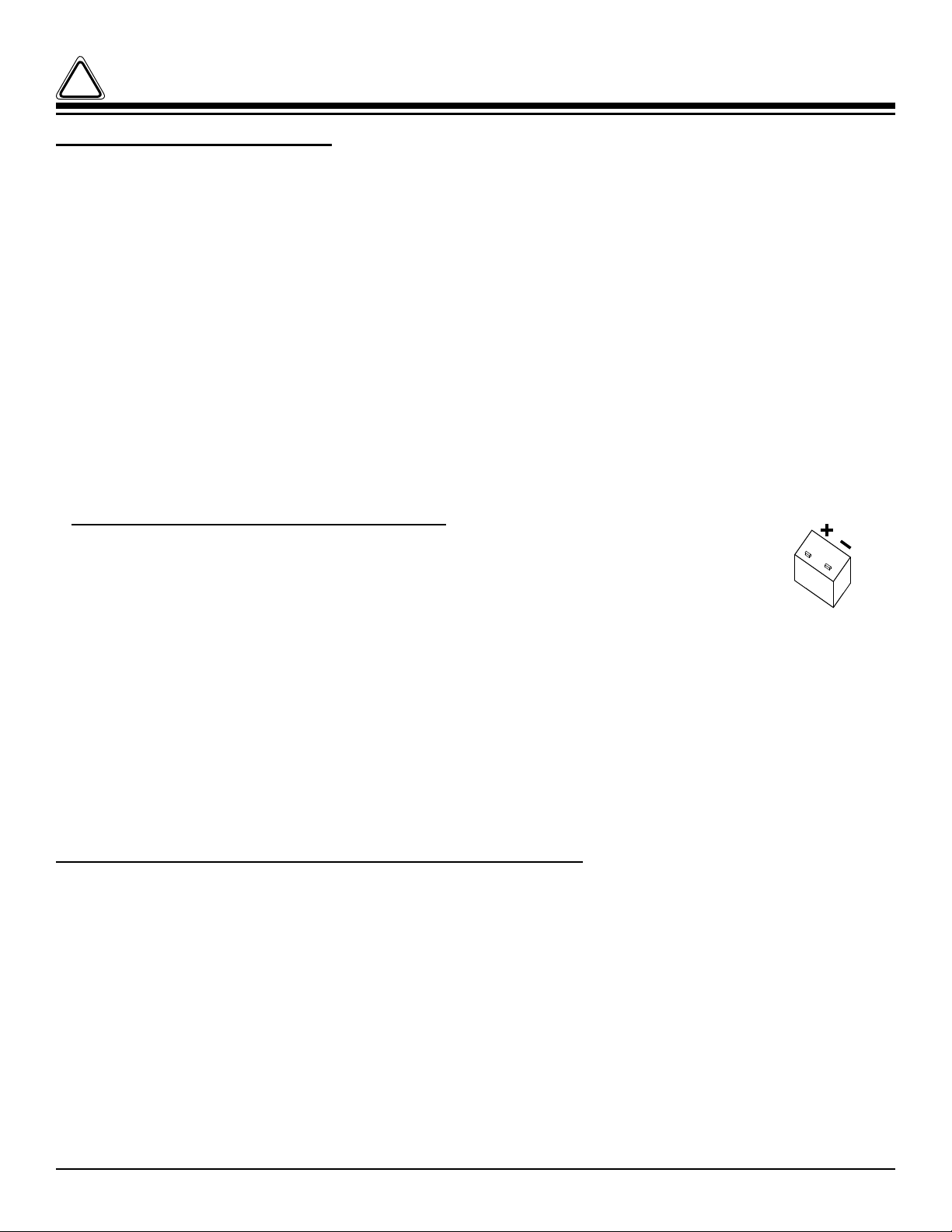

•Thiscontrolsystemalsoincludesabatterybackupsystemtocontinueoperationof

the bed in the event of a main power failure or during transport.

•Itisnotintendedforextendeduse,andshouldbeusedonlywhennecessaryto

accommodate patient comfort.

•Thebackupbatterywillprovidetheopportunityforseveraladjustmentsforpatient

comfort or transport during power outage.

•Inthesituationofanextendedpoweroutageitisrecommendedthatthepatientbe

removed from the bed.

POWER AND BATTERY OPERATION

•TheelectronicssystemoftheTri-FlexIIbedoperatesfromalowvoltage

power supply located under the head of the bed. To insure optimum battery

charge, please keep unit connected to a main power source.

(see optional Barri-Float / Low-Air-Loss manual for instructions on use, cleaning and disinfection)

!

ThisproducthasbeentestedtoconrmcompliancewiththeappropriateEMCstandardsac-

cording to CISPR 11, Class B.

Mostelectronicequipmentisinuencedbyradiofrequencyinterference(RFI).Cautionshould

be exercised with regard to the use of portable communications equipment in the area around such

equipment. While Burke has made every effort to ensure that RFI does not cause problems, very

strong signals could cause a movement of a section of the bed. Such movement would be of very

short duration and travel.

Itistheresponsibilityofthehealthcareprovidertoconrmthatcellphonesandotherportable

communications devices will not cause erratic behavior of other equipment. In the event that RFI does

cause erratic behavior, turn off the communications device as soon as possible. For maximum safety do

not operate the affected equipment until the source of the interference is removed. Report any malfunc-

tionstoqualiedservicepersonnel.

Electromagnetic Compatibility (EMC)