3

1 ABOUT THESE INSTRUCTIONS .......................................... 4

1.1 Auxiliary materials ....................................................... 4

1.2 Symbols....................................................................... 4

2 AUTHORIZED USE ............................................................... 5

3 BASIC SAFETY INSTRUCTIONS.......................................... 5

4 GENERAL INFORMATION .................................................... 6

4.1 Contact addresses ...................................................... 6

4.2 Warranty ...................................................................... 6

4.3 Information on the Internet.......................................... 6

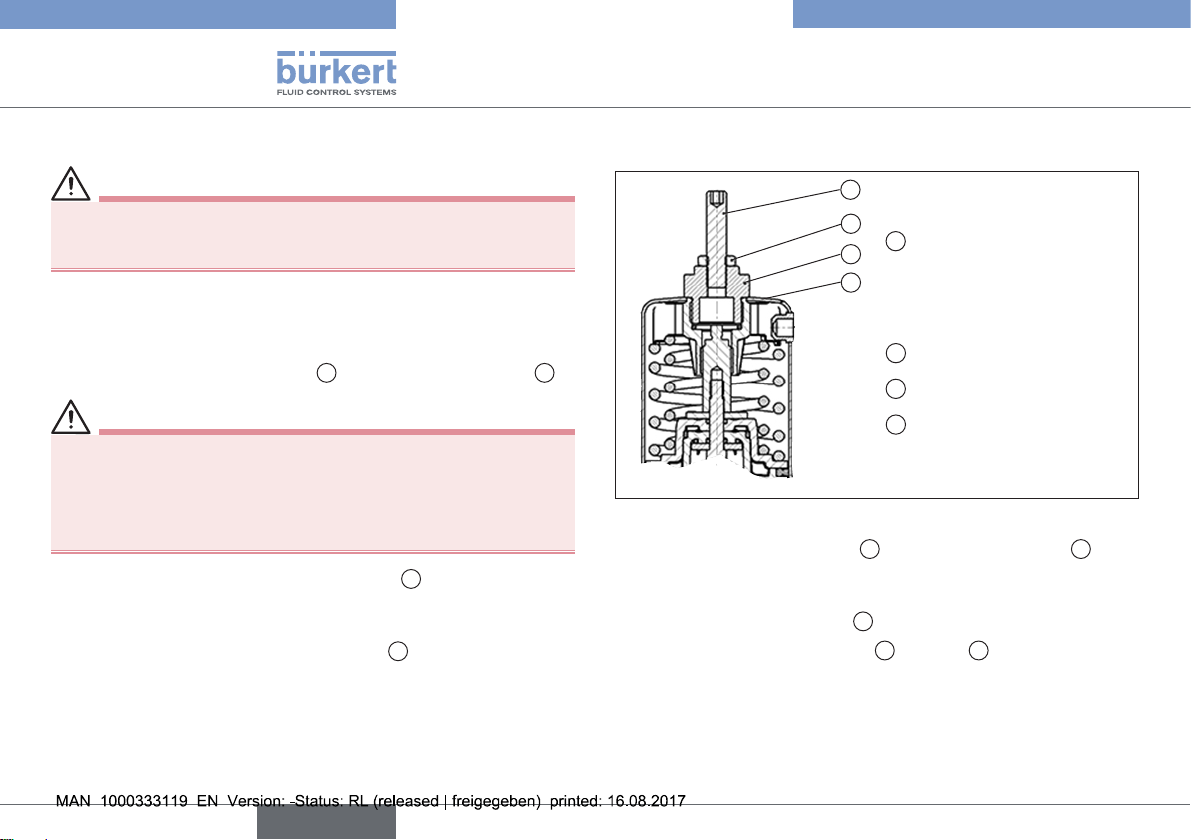

5 OVERVIEW OF OPTIONS ..................................................... 7

5.1 Max stroke limit ........................................................... 7

5.2 Min and max stroke limit ............................................. 7

5.3 Threaded nipple for inductive proximity switch

M12 x 1........................................................................ 8

5.4 Mounting bracket for two inductive proximity

switches M12 x 1 ........................................................ 8

5.5 Electrical position indicator Type 8697

(with adaptation).......................................................... 9

6 OPTION: MAX STROKE LIMIT ............................................. 9

6.1 Before installation...................................................... 10

6.2 Installation of the max stroke limit............................. 10

7 OPTION: MIN AND MAX STROKE LIMIT ........................... 11

7.1 Before installation...................................................... 11

7.2 Installation of the min and max stroke limit,

actuator size D and M ............................................... 12

7.3 Installation of the min and max stroke limit,

actuator size N and P ................................................ 13

8 OPTION: THREADED NIPPLE ............................................ 14

8.1 Tasks before installation ............................................ 15

8.2 Installing the threaded nipple .................................... 15

9 OPTION: MOUNTING BRACKET........................................ 16

9.1 Tasks before Installation............................................ 17

9.2 Installing the mounting bracket,

actuator size D and M ............................................... 17

9.3 Installing the mounting bracket,

actuator size N and P ................................................ 19

10 OPTION: POSITION FEEDBACK TYPE 8697..................... 21

10.1 Tasks before installation ............................................ 22

10.2 Installing the position feedback,

actuator size D and M ............................................... 22

10.3 Installing the position feedback,

actuator size N and P ................................................ 24

10.4 Electrical installation.................................................. 26

11 ORDER NUMBERS ............................................................. 26

Contents

Type 2060, 2061, 2063, 2064, 2065

English