3

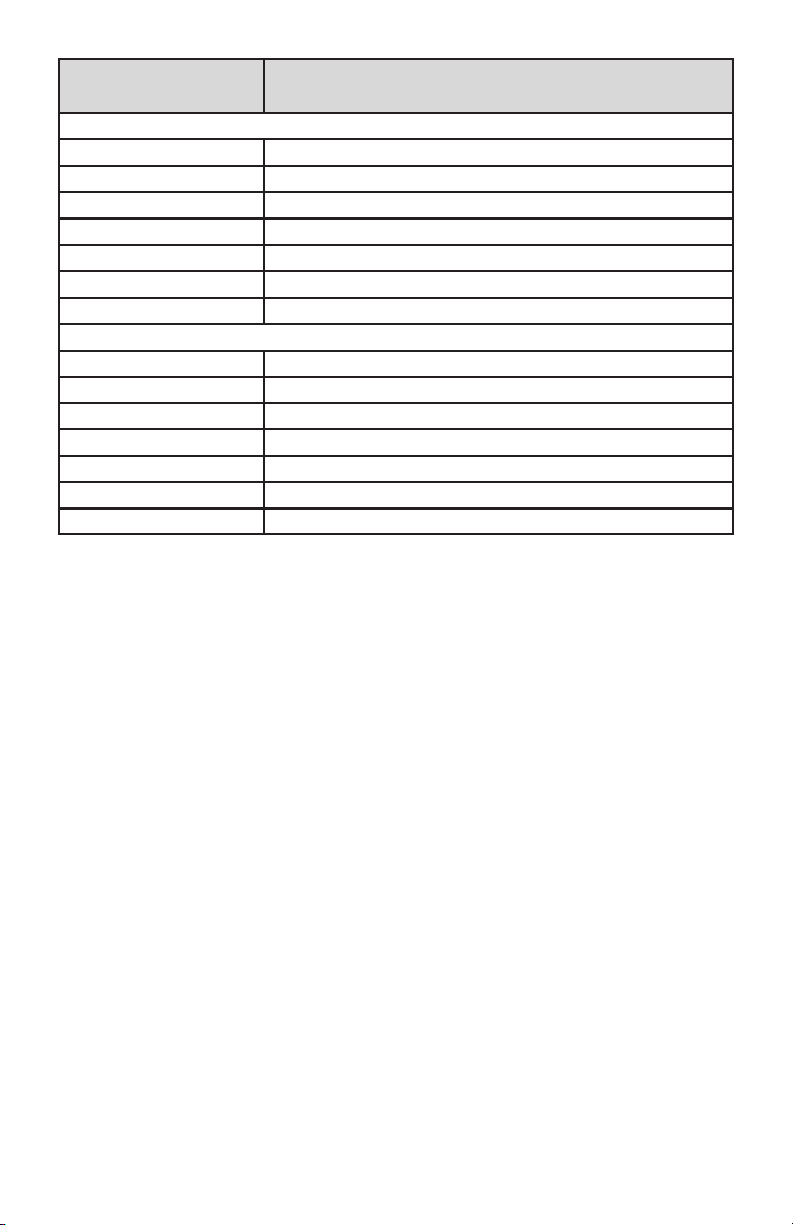

Table of Contents

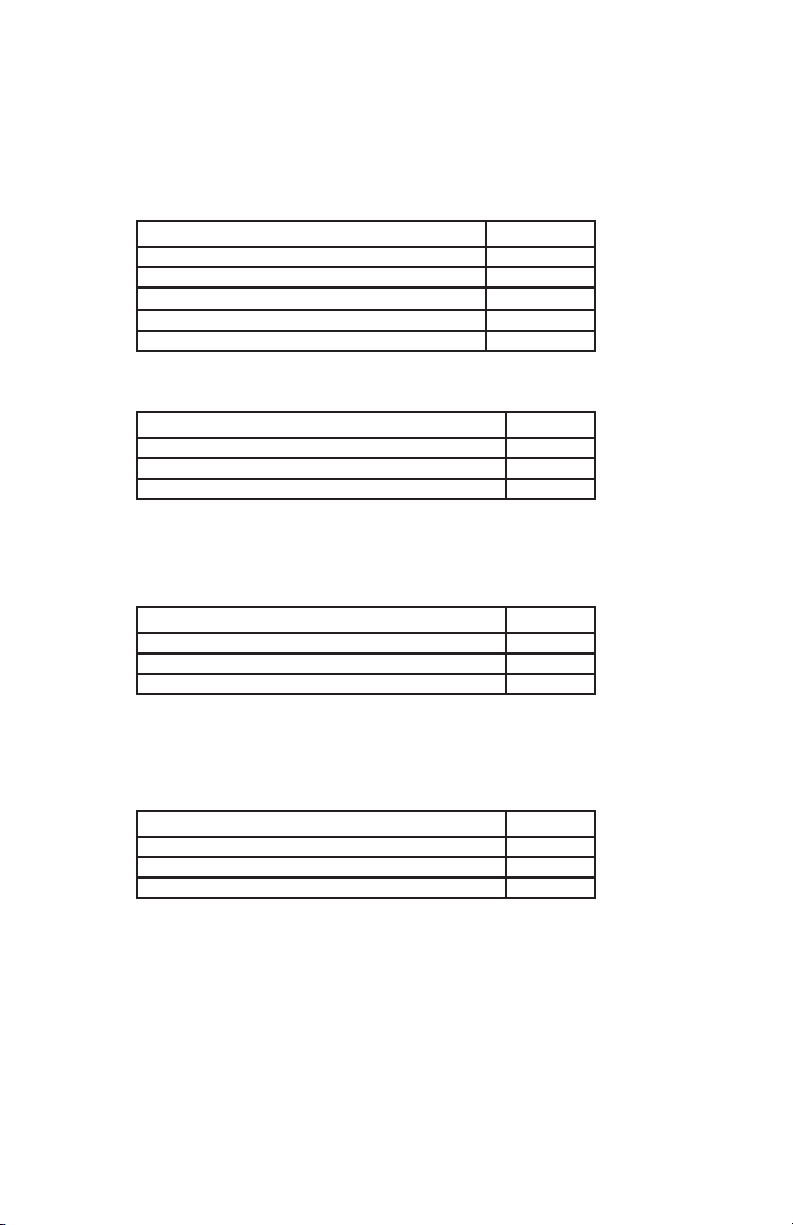

1.0 Tools List .............................................................................................. 4

2.0 Parts List............................................................................................... 4

2.1 Floor Model ..................................................................................... 4

2.2 Wall Model ...................................................................................... 5

2.3 Single Ceiling Model........................................................................ 5

2.4 Double Ceiling Model ...................................................................... 5

3.0 Safety Instructions................................................................................. 6

3.1 Symbols .......................................................................................... 6

3.2 Safety Precautions........................................................................... . 6

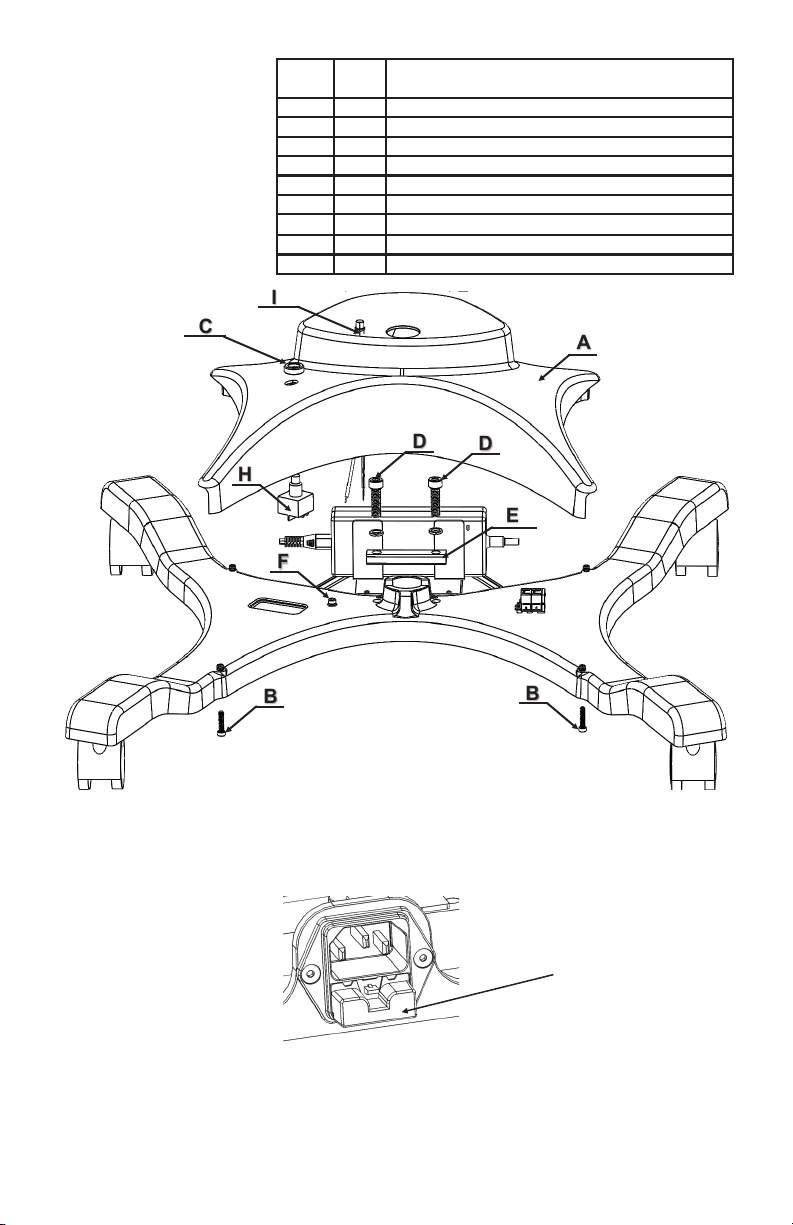

4.0 Floor Stand Model ................................................................................ 7

4.1 Base Post Assembly................................................................... ..... 7

4.2 Handle Assembly.............................................................................12

4.3 Spring Arm Assembly..................................................................... 14

4.3.1 Elbow Cover Removal Instructions ........................................ 15

5.0 Wall Mount Model ............................................................................... 17

5.1 Mounting Height ........................................................................... 17

5.2 Ranges of Motion ....................................................................... ..17

5.3 Installation (Wall Support and Anchorage)..................................... 18

5.4 Connecting Power.......................................................................... 20

5.4.1 Wall Switch Wiring................................................................. 20

5.4.2 Wall Mount Wiring ................................................................. 21

6.0 Ceiling Mount Models............................................................................ 22

6.1 Mounting Height........................................................................... ... 22

6.2 Support and Anchorage................................................................. 22

6.3 Cutting the Down Tube................................................................. .. 23

6.4 Ranges of Motion.............................................................................23

6.5 Ceiling Installation (AIM HI LED Single or Double Ceiling Model)......24

6.6 Installing the Junction Box............................................................. 25

6.7 Installing the Ceiling Casting............................................................25

6.8 Installing the Down Tube..................................................................25

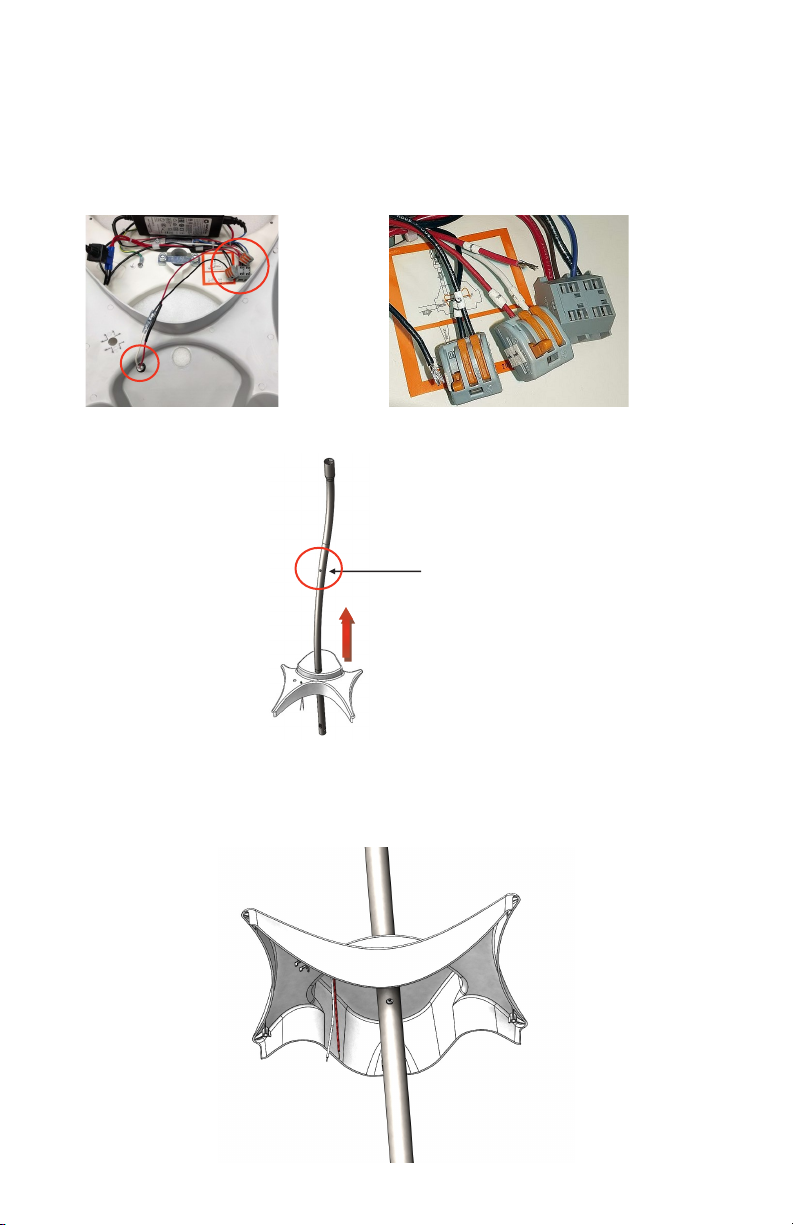

6.9 Connecting Power ......................................................................... 27

6.9.1 Wall Switch Wiring.................................................................. 28

6.9.2 Ceiling Mount Wiring .............................................................. 29

6.10 Ceiling Bell Housing Assembly .................................................... 30

7.0 Extension/Spring Arm - Wall and Ceiling Assembly.................................30

8.0 Mounting the Light Head to the Spring Arm........................................ ... 34

9.0 Cleaning ............................................................................................... 35

9.1 Normal Cleaning............................................................................. 35

9.2 Extensive Cleaning......................................................................... 35

10.0 Equipment Anchorage Diagrams ........................................................ 36

11.0 AIM HI LED Single/Double/Wall Mount Wiring Diagram......................... 40

12.0 Warranty Information........................................................................... 41

13.0 Equipment Maintenance Log............................................................... 42

Burton Medical Information ......................................................................... 44