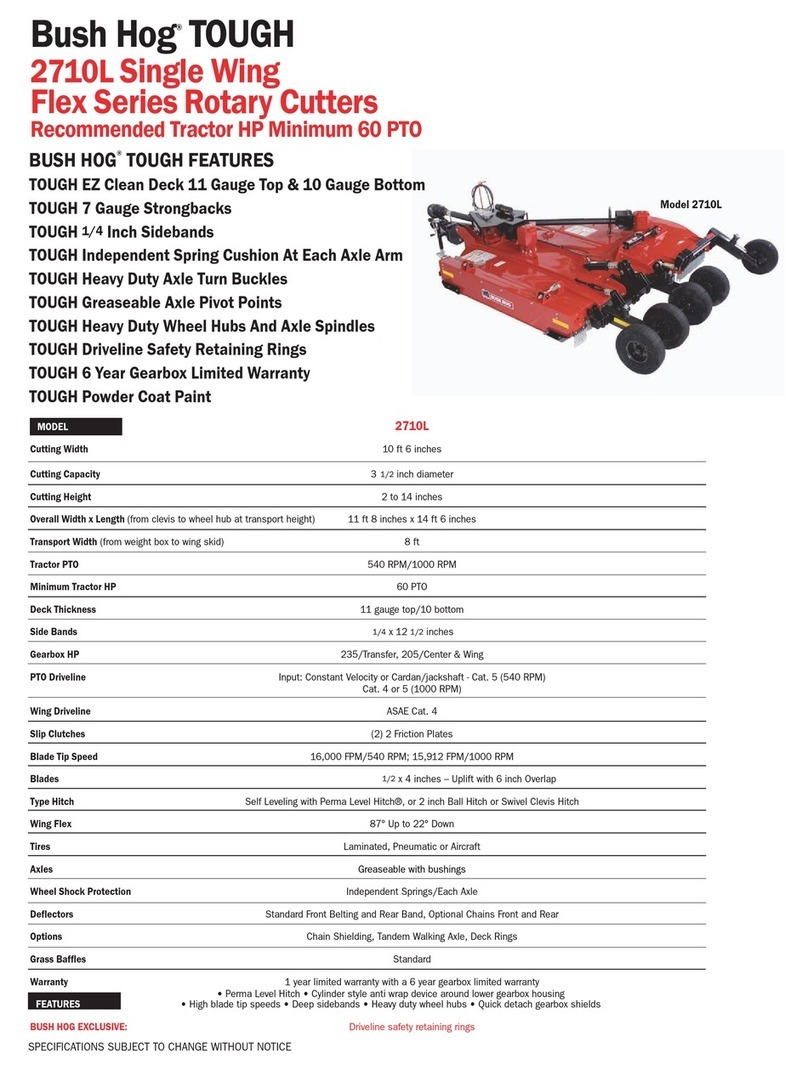

2-2 OPTIONAL VALVE MOUNTING

BRACKET INSTALLATION (Figure 2-2)

A. Place bottom bracket at desired mounting loca-

tion. Mark 2-4 holes (as needed) for drilling using

bracket as pattern. Drill holes using 13/32 drill bit.

B. Mount lower bracket using four 3/8 x 1-1/2” bolts,

nuts, flatwashers and lockwashers.

C. Attach valve to top bracket using three 3/8” x 2-

1/2” bolts, nuts and lockwashers.

D. Mount top bracket to bottom bracket using quar-

ter turn fasteners. Insert quarter turn fastener into clip-

on receptacle and turn 90 degrees.

Figure 2-1

Tractor Drawbar Adjustment

8

E. Connect hydraulic lines to tractor auxiliary out-

let(s).

F. Unpin wing lift cylinders at rod end. Fully ex-

tend cylinders by pulling on clevis. Retract cylin-

ders using hydraulic valve. This removes most of

the air from cylinder. Repin cylinders.

. Attach driveline on tractor and cutter with constant

velocity joint at tractor. Pull on each driveline section to

be sure yokes lock into place. Make certain driveline

shielding is in place and in good condition.

H. If optional pillow block driveline assembly is used,

slide spacer bushing onto end of jackshaft before in-

stalling driveline. This will insure proper space will be

maintained between the bearing and the driveline yoke.

(Figure 5-15)

I. Attach driveline shield chains from both ends of dri-

veline shielding to stationary location. NOTE: The

shield around the constant velocity joint should not

be chained in place.

J. Remove jackshaft and pin in storage position on

deck.

B. Raise cutter using jackstand until tongue is at

drawbar height.

C. Connect cutter to tractor using 1-inch (25.4mm)

diameter approved pin with lynch pin retainer or equiv-

alent.

D. If optional valve is used, mount as desired. If op-

tional valve mounting bracket is used with valve, at-

tach to tractor as described in paragraph 2-2.

2-1 ATTAC ING TO TRACTOR

A. IMPORTANT - Adjust tractor drawbar length

to dimension shown in Figure 2-1. Incorrect draw-

bar length will change angle of driveline causing

possible damage to constant velocity joint. Do

not use PTO adapters. Use of PTO adapters will

invalidate your warranty. See operator’s manual for

drawbar adjustment procedures.

CAUTION

USE A PIECE OF CARDBOARD OR WOOD RAT ER

T AN ANDS AND WEAR EYE PROTECTION W EN

SEARC ING FOR YDRAULIC LEAKS. ESCAPING Y-

DRAULIC OIL UNDER PRESSURE CAN PENETRATE

SKIN. IF OIL IS INJECTED INTO SKIN, IT MUST BE SUR-

GICALLLY REMOVED WIT IN A FEW OURS BY A

DOCTOR OR GANGRENE MAY RESULT.

2-3 PITC ADJUSTMENT

The pitch of the cutter (front to rear) is controlled by

adjusting the linkage rods (Figure 2-3). Shortening

the linkage rod assemblies will raise the front of

the cutter. Lengthening the linkage rod assem-

blies will lower the front of the cutter. The pitch

adjustment is primarily for compensating for the dif-

ferent height of tractor drawbars. It should be noted

that altering linkage rod length requires the cutting

height to be reset also. As described in the following,

it can also be used to alter the cutting performance.

Note that operating the cutter at any pitch other than

parallel to the ground will produce a slightly uneven

cut.

Figure 2-2

Valve Bracket

Installation

3/8” ex Nut

3/8” Lockwasher

ydraulic

Valve

Valve Plate

3/8” x 2-1/2” Capscrew

(3 Furnished)

Base

Plate

Tractor Fender

3/8 x 1- 1/2” Capscrew

3/8” Flatwasher

3/8” Lockwasher

3/8” ex Nut

SECTION II

PREPARATION FOR USE