cab Produkttechnik GmbH & Co KG

3

PRODUCTMARKINGANDBARCODEIDENTIFICATION

3

Table of Contents

e4 series Operator´s manual

copyright © cab Produkttechnik GmbH & Co KG......................................................................... 2

Tableof Contents ......................................................................................................................... 3

FCC Notice .................................................................................................................................. 4

ImportantSafetyInstructions ....................................................................................................... 5

PossibleCorrectiveAction ........................................................................................................... 5

Preface ........................................................................................................................................ 5

Chapter 1Introduction .................................................................................................................. 6

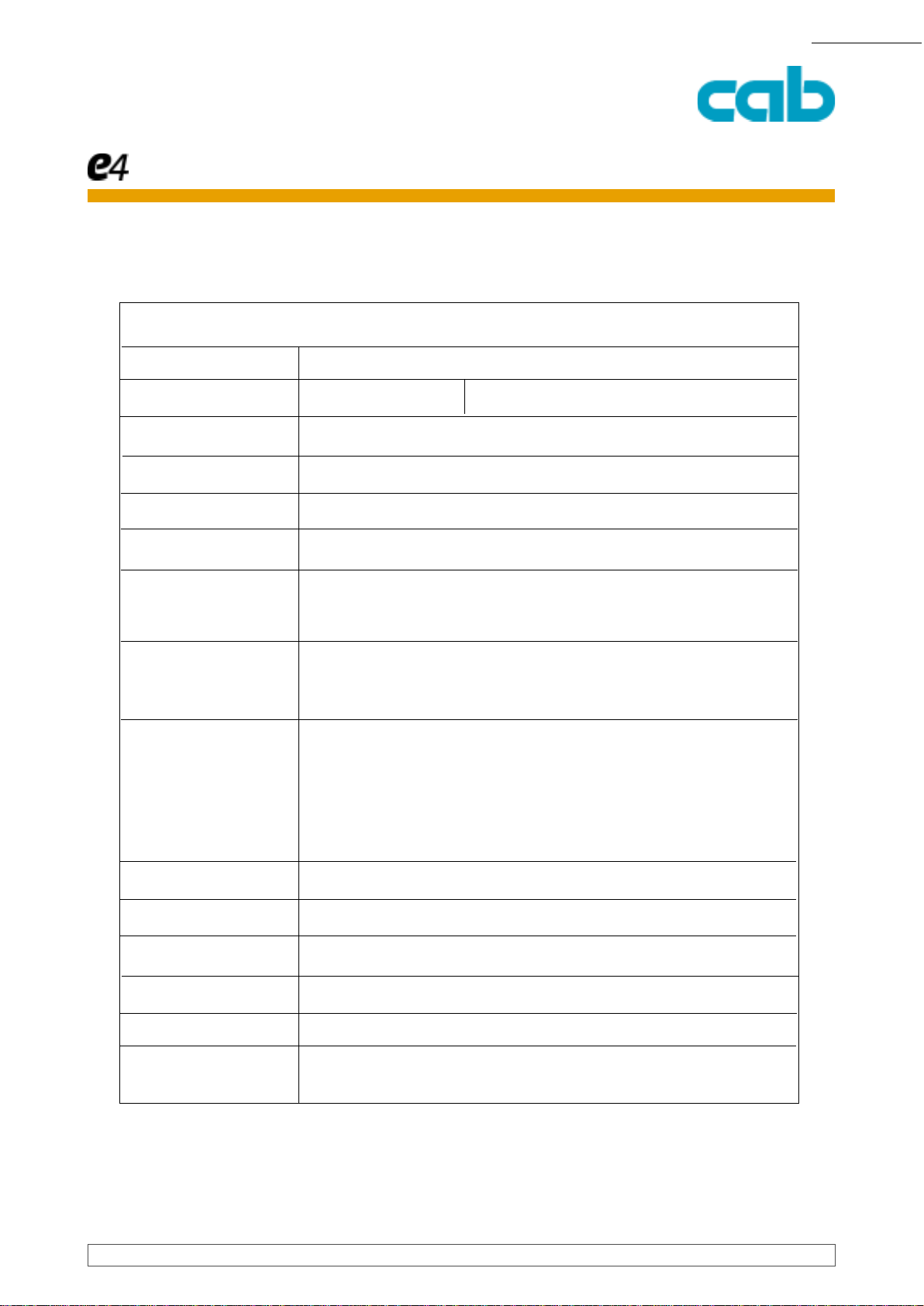

Printer Specifications .................................................................................................................. 6

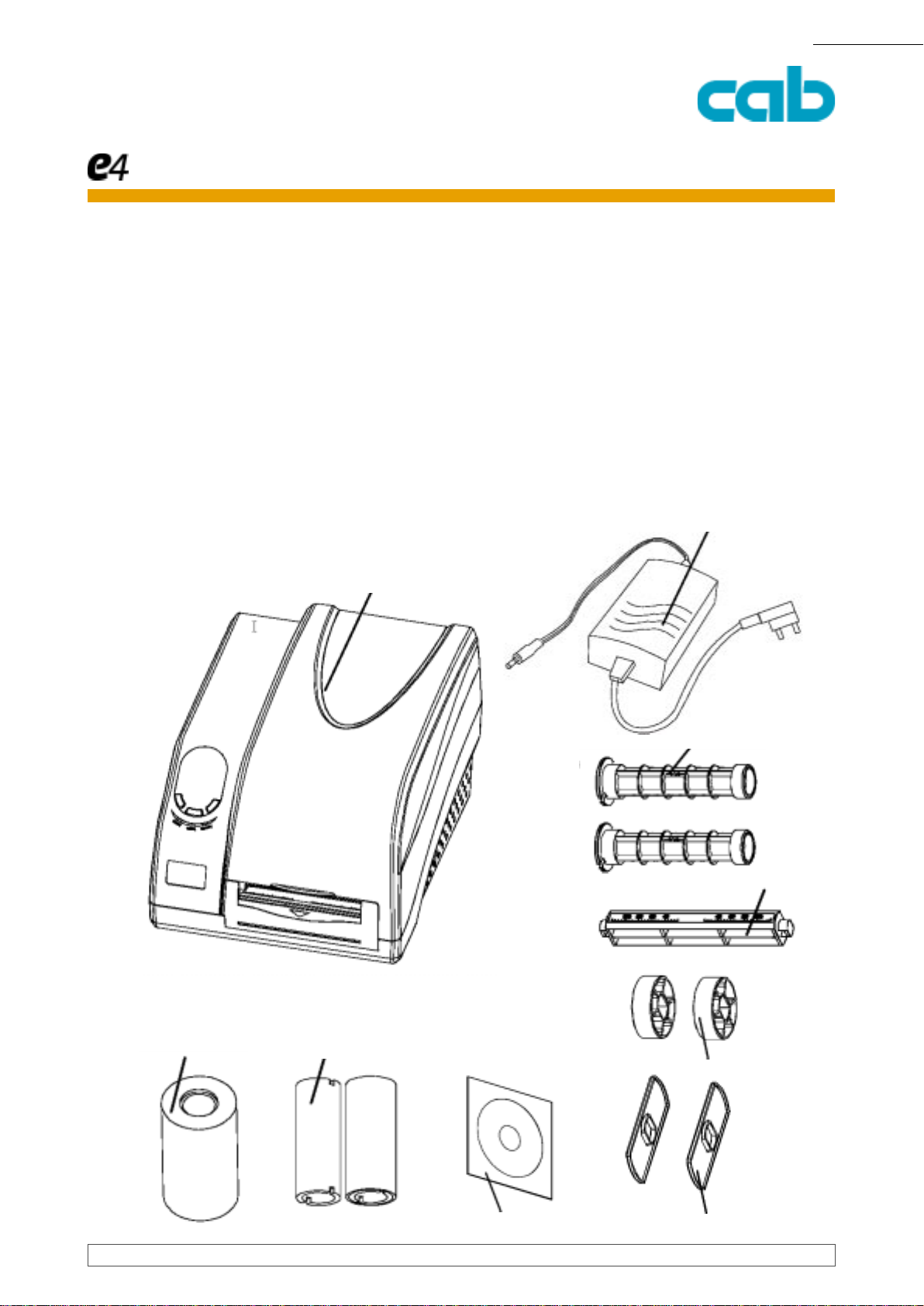

UnpackingandInspection ............................................................................................................ 7

PackingList¨Figure 1: .................................................................................................................. 7

Chapter2Getting Started............................................................................................................. 8

Settingup .................................................................................................................................... 8

ConnectingthePrinter ................................................................................................................. 8

InterfaceConnection .................................................................................................................... 9

MainParts and Features.............................................................................................................10

Description .................................................................................................................................11

LoadingtheRibbon .....................................................................................................................12

LoadingtheMedia ......................................................................................................................16

Adjusting the Position of Media Sensor.......................................................................................17

Mediasensing ............................................................................................................................18

Mediasensing ............................................................................................................................19

OperationBasics ........................................................................................................................20

PowerSwitch..............................................................................................................................20

TheFrontPanel ..........................................................................................................................20

IndicatorLamps ..........................................................................................................................20

Buttons......................................................................................................................................21

System Mode .............................................................................................................................21

MediaSensorCalibration ............................................................................................................22

SelfTest .....................................................................................................................................22

DIP Switch at the Back Panel.....................................................................................................23

WindowsDriverInstallation .........................................................................................................24

LabeleditionsoftwareeLABEL ...................................................................................................24

Chapter3Maintenance ...............................................................................................................25

Warning: .....................................................................................................................................25

CleaningthePrinthead................................................................................................................25

Chapter4 Troubleshooting ..........................................................................................................26

ErrorIndications..........................................................................................................................26

AppendixA: Interface Specifications ...........................................................................................28

RS232Serial...............................................................................................................................28

Parallel(Centronics)....................................................................................................................29

AppendixB:ASCIITable .............................................................................................................30