1

50ZPB,C,D,50ZHB,C,

PA 3 Z --- A , P H 3 Z --- A , PA 4 Z , P H 4 Z ,

PAJ4,PHJ4,WJA4,WJH4

Installation Instructions

SMALL PACKAGED PRODUCTS (SPP)

Accessory Electric Heaters 5---20 kW

For 14 SEER, R ---410A

Manufactured Home

NOTE: The Dual Point Kit can only be installed on units

equipped with a 2nd electrical entry (knockout), the knockout was

added to the electrical panel starting with the following unit serial

numbers:

2711X_____andlater

X1127_____andlater

NOTE: Read the entire instruction manual before starting the

installation.

NOTE: Installation Instructions include Single and Dual point

connection instructions separately.

SAFETY CONSIDERATIONS

Improper installation adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause death, personal injury, or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory--authorized kits or accessories

when modifying this product Refer to the individual instructions

packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Use quenching cloth for brazing operations.

Have a fire extinguisher available. Read these instructions

thoroughly and follow all warnings or cautions included in

literature and attached to the unit. Consult local building codes, the

current editions of the National Electrical Code (NEC) NFPA 70.

In Canada refer to the current editions of the Canadian Electrical

Code CSA C22.1.

Recognize safety information. This is the safety--alert symbol .

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury. Understand

these signal words; DANGER, WARNING, and CAUTION. These

words are used with the safety--alert symbol. DANGER identifies

the most serious hazards which will result in severe personal injury

or death. WARNING signifies hazards which could result in

personal injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation.

Before proceeding with heater installation, inspect thoroughly for

shipping damage. Notify shipper immediately if any damage is

found. Clean all dirt, dust and moisture from heater package.

Check for proper clearances of live parts, between phases and to

ground. Make sure that all required barriers are in place. Check

conductors run in multiple to insure that they are properly wired.

Refer to unit installation instructions for complete unit installation

details. The minimum air quantity for safe electric heater operation

is shown in Table 2.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before performing installation, service or maintenance

operations on this system, turn off all main power to system.

There may be more than one disconnect switch. Turn off

accessory heater power switch if applicable. Lock out and

tag switch with a suitable warning label.

!WARNING

DESCRIPTION AND USAGE

These heaters are comprised of a separate heater module mounted

on the blower inlet and remote mounted controls located in the unit

control box. Heater models are provided with single point electrical

connections for powering both the heater and the unit.

These heaters are intended for use only in SPP units as noted in

Table 1.

PACKAGE CONTENTS

Electric Heater Package Contents

1. Heater assembly, comprised of heater module and control

panel

2. UPC heater label

3. Installation Instructions

4. Identification label

5. Wiring label

6. Wire connectors (2)

7. Wire tires--6” (5)

8. Screws #10B (4)

9. Ground lug (1) (See Fig. 8)

10. Bolts 3/8--16 (3)

11. Plug attachment plate

12. Dual Point Electric Rating Label

13. Dual Point Warning Label

INSTALLATION

Single Point Heater Installation

1. Open all electrical disconnects and install lock--out tag

before beginning any installation or service work.

2. Check for proper heater application in Table 1.

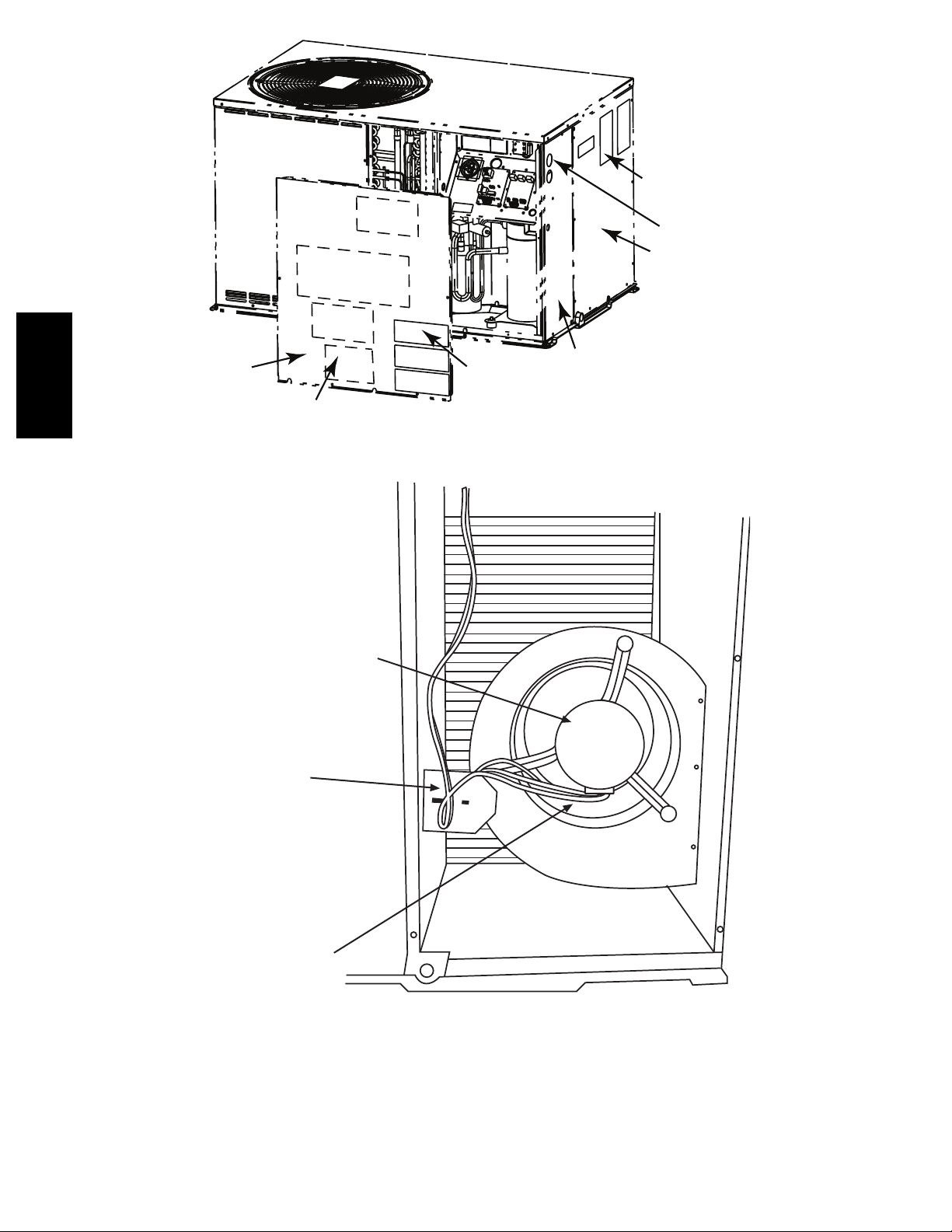

3. Remove unit side panel to access blower compartment (See

Fig. 1 and Fig. 2).

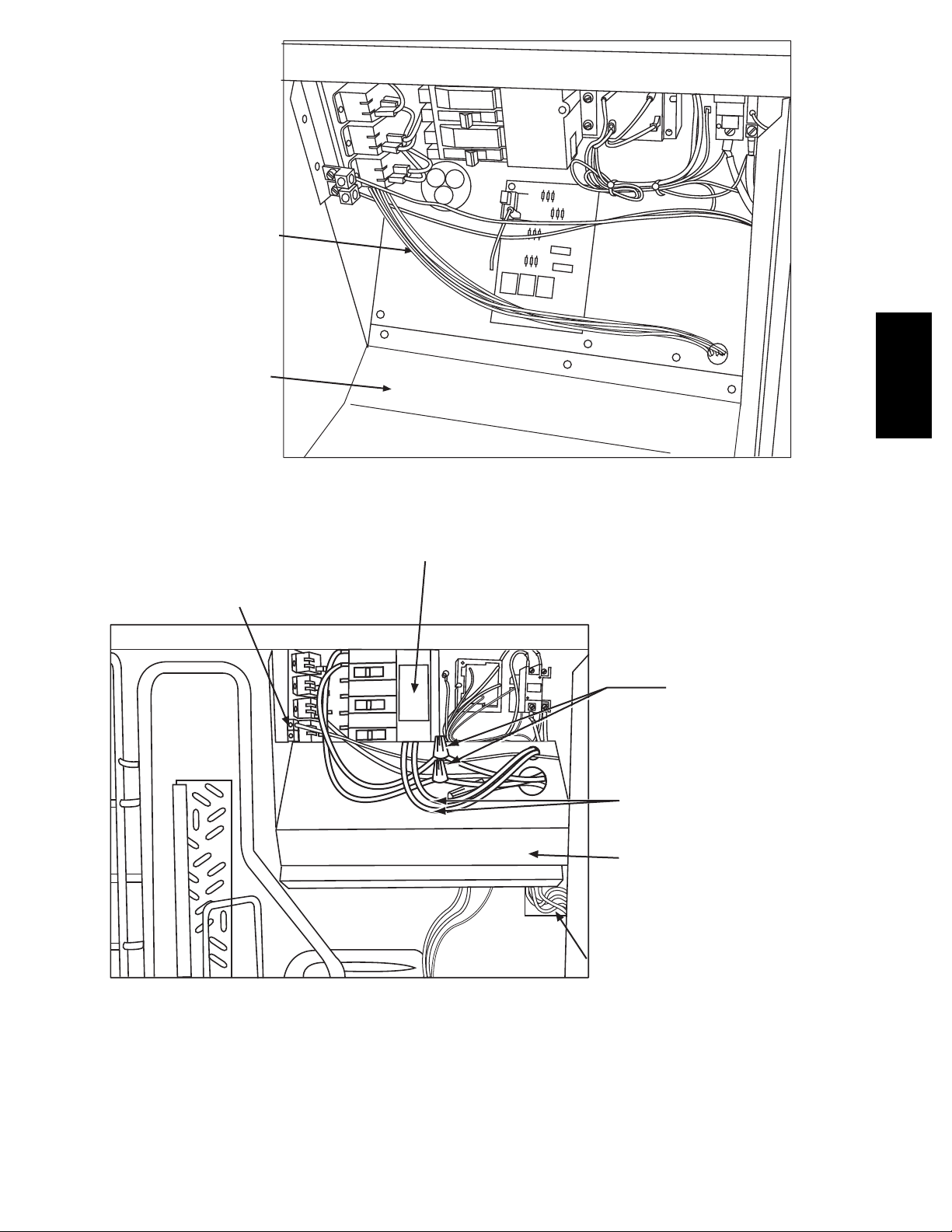

4. Disconnect wiring to motor by removing speed selection

and power plugs from bottom of motor (See Fig. 2).

5. Remove rear blower support bracket. Remove shipping

block and label under blower if unit has one (See Fig. 2).

6. Remove screws securing blower to front blower support

bracket; slide blower out of unit.