3

IMPORTANT SAFETY INFORMATION

INSTALLER: Please read all instructions before servicing

this equipment. Pay attention to all safety warnings and

any other special NOTES highlighted in the manual.

Safety markings are used frequently throughout this

manual to designate a degree or level of seriousness and

should not be ignored. WARNING indicates a potentially

hazardous situation that if not avoided, could result in

personal injury or death. CAUTION indicates a potentially

hazardous situation that if not avoided, may result in minor

or moderate injury or property damage.

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

• Children should be supervised to ensure that they do

not play with the appliance.

WARNING:

ELECTRICAL SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property

damage.

• Before servicing, disconnect all electrical

power to the unit.

• When servicing controls, label all wires

prior to disconnecting. Reconnect wires

correctly.

• Verify proper operation after servicing.

WARNING:

Unless noted otherwise in these instructions,

only factory authorized parts or accessory

kits may be used with this product.

Improper installation, service, adjustment,

or maintenance may cause explosion,

fire, electrical shock or other hazardous

conditions which may result in personal

injury or property damage.

• Use caution when removing components or handling

this product. Personal injury can occur from sharp

metal edges present in all sheet metal constructed

equipment.

ELECTRICAL SUPPLY

• If the unit was previously installed without electric heat,

the existing supply wiring may not be sufficient to handle

the increased load. See the unit rating label or

Table 8 (page 11), Table 9 (page 12) and Table 10 (page 13)

for minimum circuit ampacities and maximum overcurrent

protection ratings.

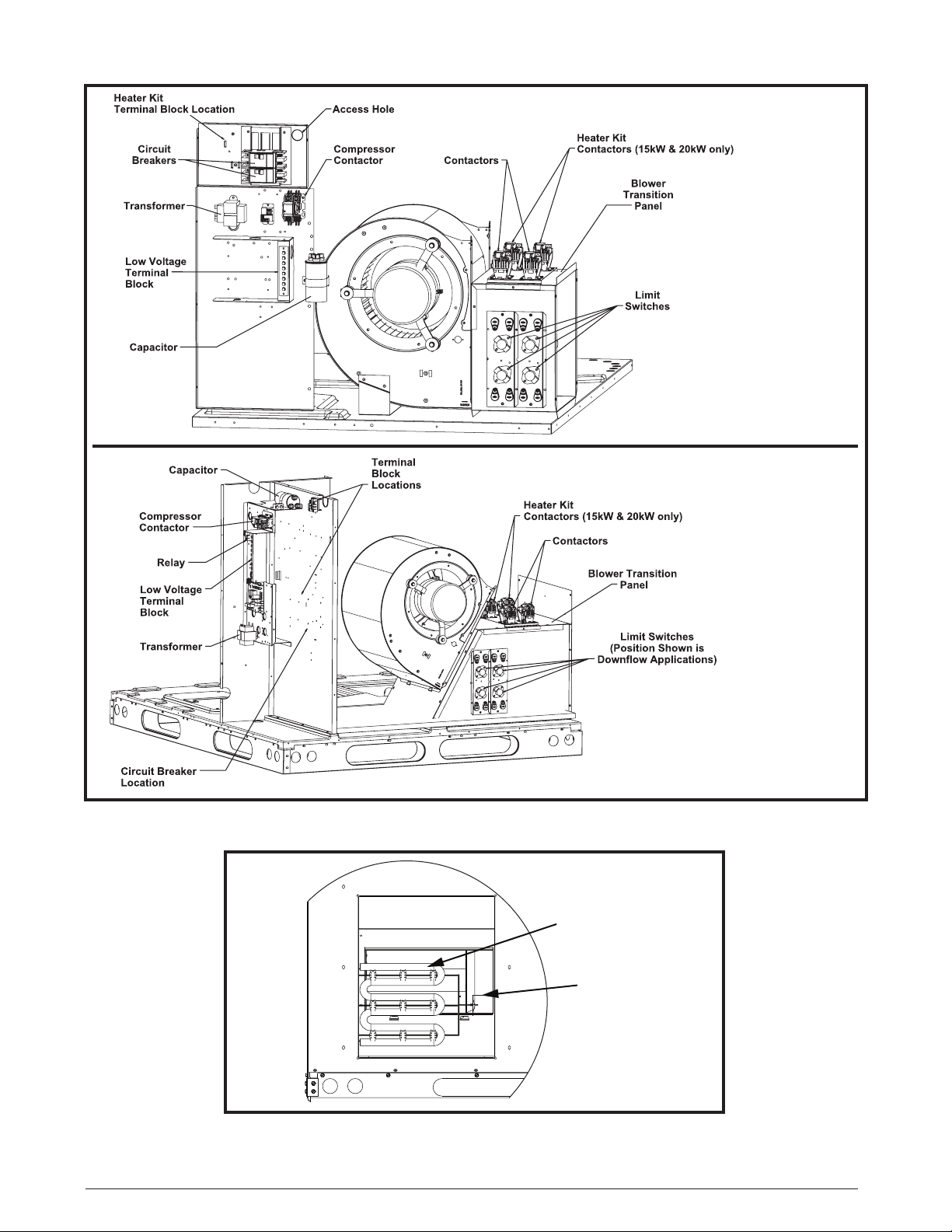

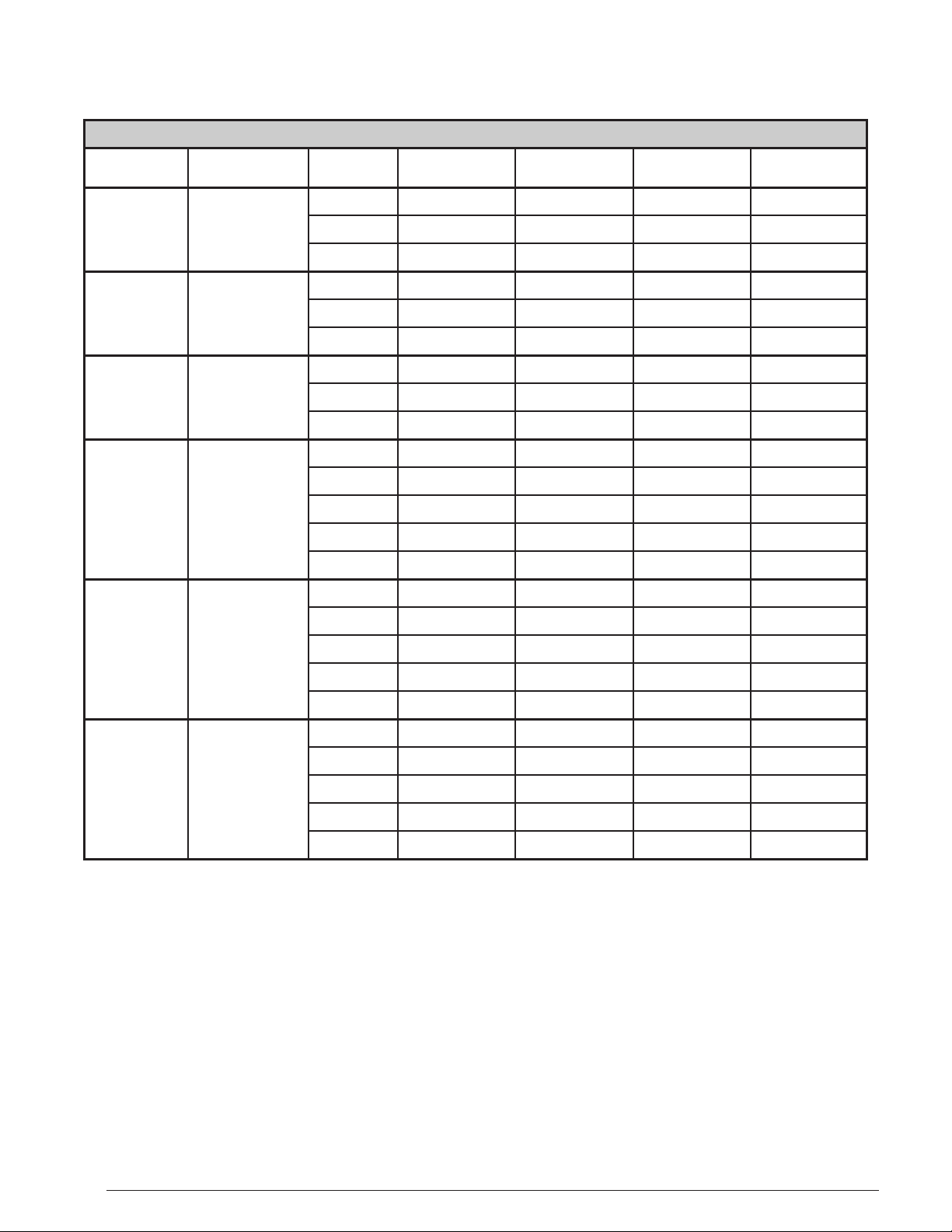

• Units with installed electric heat may be supplied by a single

circuit or by multiple circuits. Additional accessory kits

may be required if single circuit installation and/or circuit

breakers are desired. See Figure 1 for kit identification

and Table 1 for part numbers and accessory descriptions.

Circuit Options

The units with electric heat may be wired for single or

multiple circuits and may have circuit breakers or terminal

blocks. NOTE: Circuit breakers installed in the unit are

for short- circuit protection of the internal wiring and to

serve as a unit disconnect. The circuit breakers DO NOT

provide overcurrent protection of the supply wiring.

• Overcurrent protection must be provided at the branch

circuit distribution panel even if circuit breakers are not

used in the units. It must be sized as shown in

Table 8 (page 11), Table 9 (page 12) and Table 10

(page 13) or on the unit rating label and according to

the National Electric Code, Canadian Electrical Code

and applicable local codes. NOTE: In most cases the

overcurrent protection specified on the unit rating label

is less than the 60 amp rating of the circuit breakers

used in the units. This is because the function of the

overcurrent protection required at the distribution

panel (field supplied) and the unit mounted breakers

is different.

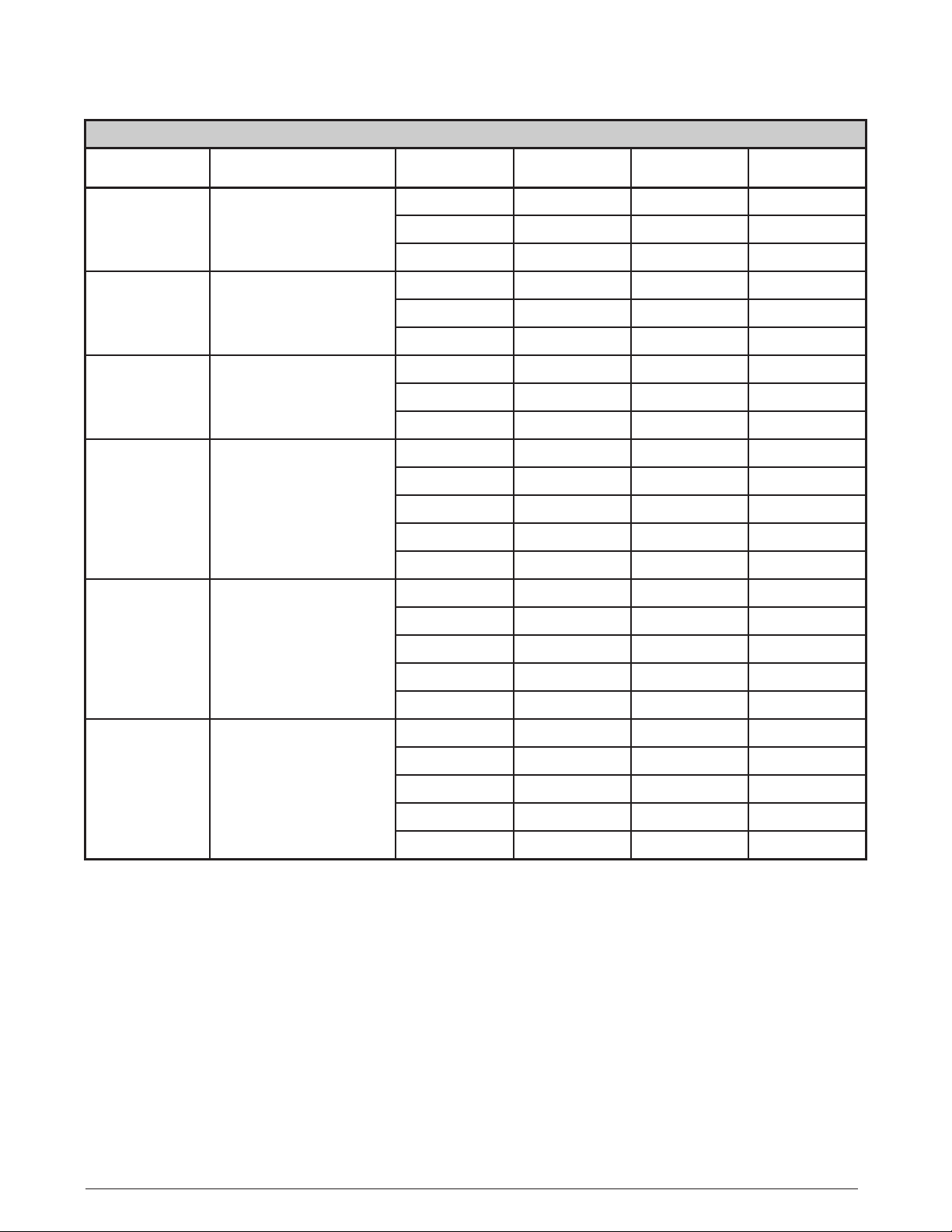

• When circuit breakers are used they must be used on

all circuits. Refer to Table 5 (page 8), Table 6 (page 9)

and Table 7 (page 10) for the correct circuit breaker for

the application.

• If the number of circuits listed in Table 5 (page 8),

Table 6 (page 9) and Table 7 (page 10) are more than

1, circuit breakers are required. If single circuit supply

wiring is desired: Use the 4-pole circuit adapter kit (P/N

GENERAL INFORMATION

H3HK heater kits are approved for use in packaged air

conditioners and packaged heat pumps when applied

and installed according to these instructions. See

Table 5 (page 8), Table 6 (page 9) and Table 7

(page 10) for approved H3HK air conditioner and heat

pump applications. Refer to the National Electric Code

(ANSI/NFPA 70) or in Canada the Canadian Electric

Code Part 1 (CSA C.22.1) and applicable local codes

for overcurrent protection and disconnect requirements.

Clearances to Combustibles

All units are approved for zero clearance to combustibles

when installed according to these instructions and other

instructions included with the unit and other approved

accessories. See Table 1, (page 4).