Provide with optional Modbus-to-BACnet gateway for BAS integration,

code NA10520.

Technical specifications

Mixing valve body

Materials: - Body: DZR low-lead brass

- Ball: low-lead brass, chrome-plated

- Hydraulic seals: peroxide-cured EPDM

Max. body pressure rating (static): 230 psi (16 bar)

Max. operating pressure: 150 psi (10 bar)

Max. inlet temperature: 212°F (100°C)

Temperature gauge scale: 30 - 210°F

Suitable fluids: water

Max. water hardness: 10 grains

Actuator, 3-wire floating

Electric supply: 24 VAC - 50/60 Hz

Power consumption: 6 VA

Protection cover: self-extinguishing VO

Protection class: IP 65 (NEMA 4/4X)

Ambient temperature range: 14 - 130°F (-10 - 55°C)

Electric supply cable length: 31½” (0.8 m)

Max. distance for control signal wire:

500 ft (150 m) cable 2 conductor x AWG 18

800 ft (250 m) cable 2 conductor x AWG 16

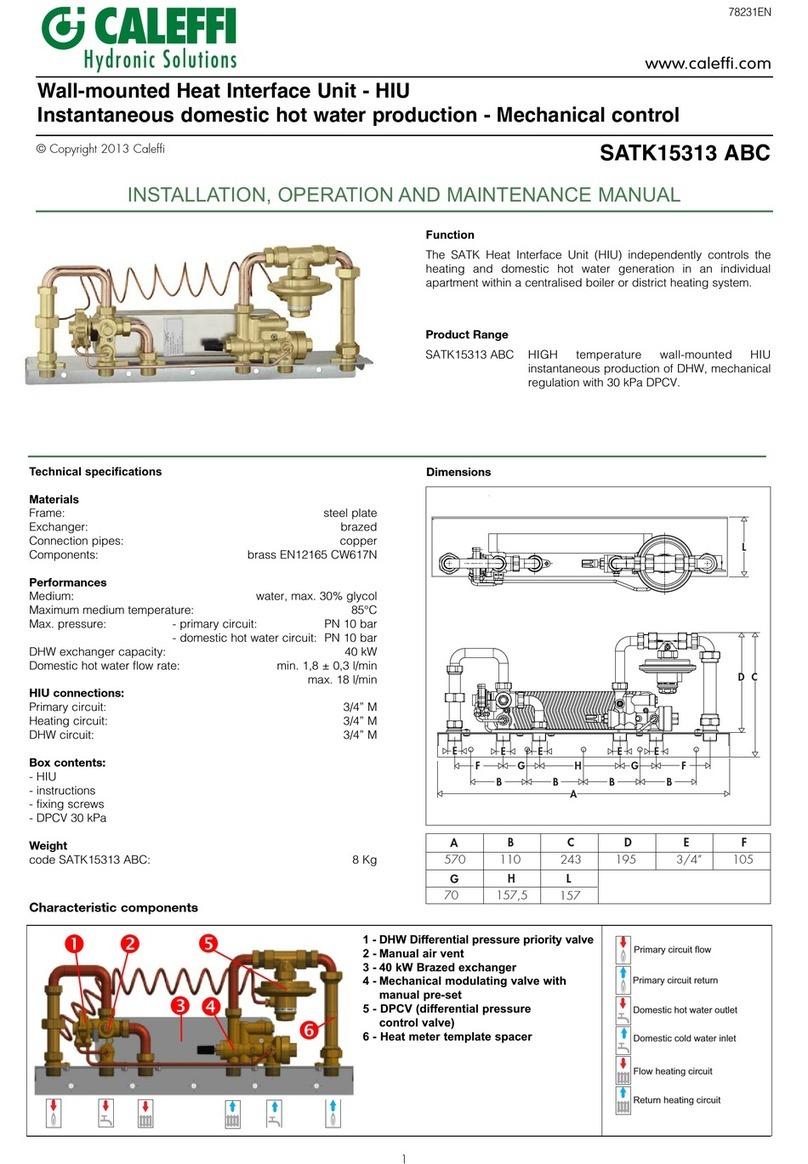

Station components

Frame: steel uni-strut

Pipes: copper type L

Ball valves: low-lead brass

Check valves: stainless steel

Main connections: -copper

1”, 1¼”, 1½”, 2” & 2½”

Controller, LCD user interface/display

Materials: - Housing: self-extinguishing ABS, color white RAL 1467

- Cover: self-extinguising SAN, smoked transparent

Electric supply: 24 VAC (min 21.6, max 26.0 VAC) - 50/60 Hz

Power consumption: 6.5 VA

Adjustment temperature range: 70 - 185°F (20 - 85°C)

Disinfection temperature range: 100 - 185°F (40 - 85°C)

Ambient temperature range: 32 - 120°F (0 - 50°C)

Protection class: IP 54 (wall mounting)

(Class II appliance)

Mounting bracket: DINrail

Mixing valve actuator current draw: 1 A max / 24 V

Alarm relay (R2): 5 A resistance (2 A inductance) / 24 V

Contact rating (R1, R3, R4): 10 A resistance (2 A inductance) / 24 V

(A 50 VA Class 2 120/24 VAC transformer is included)

Fuses: 1 (main): 80 mA

Fuses: 2 (mixing valve): 1 A

Charge reserve: 15 days in the event of electric supply failure,

with a 3 cell rechargeable 3.6 V 140 mAh buffer battery

Battery recharging time: 72 hours

Approvals: CE, FCC part 15

Temperature sensors

Body material: stainless steel

Type of sensitive element: NTC

Working temperature range: 14 - 260°F (-10 - 125°C)

Resistance: 1000 Ohms at 77° F (25° C)

Time constant: 2.5

Max. distance for mixed outlet or return (recirculation) sensor:

500 ft (150 m) cable 2 conductor x AWG 18

800 ft (250 m) cable 2 conductor x AWG 16

Mixing valve performance

Accuracy: ± 3º F (± 2º C)

Max. operating differential pressure (dynamic): 75 psi (5 bar)

Max. ratio between inlet pressures (H/C or C/H): 2.1

Certifications

1. ASSE 1017/CSA B125.3, certified by ICC-ES, file PMG-1357.

2. The valve body component meets the requirement of CSA Z317.1

Special Requirement for Plumbing Installations in Health Care

Facilities, certifed by ICC-ES, file PMG-1357.

3. The valve body complies with NSF/ANSI 372, Drinking Water System

Components-Lead Content Reduction of Lead in Drinking Water Act,

California Health and Safety Code 116875 S.3874, Reduction in

Drinking Water Act, Vermont Act 193 - The Lead in Plumbing

Supplies Law and Maryland’s Lead Free Law HB.372, as certified by

ICC-ES, file PMG-1360.

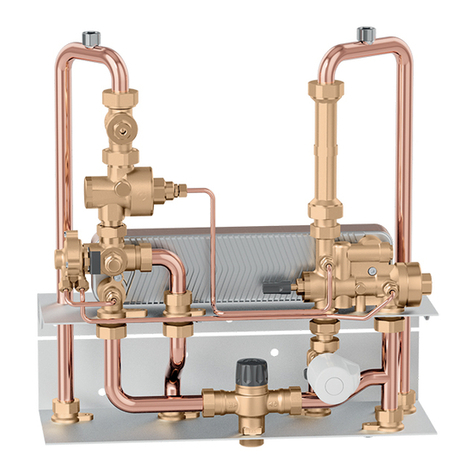

Station assembly

Includes pre-piped LEGIOMIX 3-way mixing valve with union connections,

serviceable low-lead stainless steel check valves, a recirculation connection

and isolation valves for fast and simple installation. The LEGIOMIX controller is

pre-mounted and pre-wired and includes a return water temperature sensor,

in a packaged wall mount configuration with steel uni-strut frame that can bolt

to the wall through any of the perforations. The assembly also includes copper

type L pipe, low lead ball valves and a plug-in 24 VAC transformer with 10

feet of wire.

2