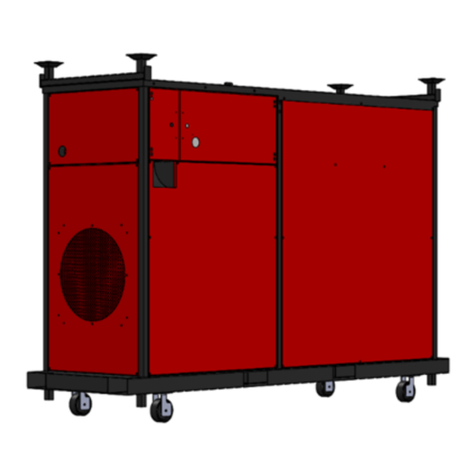

CAMPO EQUIPMENT CO. LTD. (ECOBLAZE)

6 Carson Court, Brampton, ON, CANADA, L6T 4P8

Tel: (905) 793-2525 | Fax: (905) 793-8768 | www.campoequipment.com

pg. 3

FOREWORD

This Operator's Service Manual is intended to

familiarize you with the operation of and

necessary service information for the

BLAZE DF1600 gas fired model. Please read

this manual thoroughly before operating the

Blaze DF1600.

This manual uses the words WARNING,

CAUTION, and NOTE to emphasize certain

information. WARNING identifies personal

safety related information; therefore, be sure to

read the directive because it deals with the

possibility of personal injury. CAUTION

identifies heater-related information; therefore,

be sure to read the directive because it deals

with the possibility of damaging part or parts of

the Blaze DF1600. NOTE identifies

supplementary information worthy of attention.

This manual covers operating instructions,

operator related maintenance instructions,

specifications, and service information. This

manual shouldbe considered apermanent part

of the Blaze DF1600 and must remain with the

heater at thetime of resale. If additional service

information is desired, either contact your local

dealer or write or phone:

CAMPO EQUIPMENT CO.LTD.

(ECOBLAZE)

6 Carson Court

Brampton, ON,

Canada L6T 4P8

Tel: (905)793-2525

Fax: (905) 793-8768

www.campoequipment.com

LIMITED WARRANTY

Campo Equipment CO.LTD and accessories

are warranted to the original retail purchaser.

No warranty is transferable to any subsequent

owner. The warranty period is one year from

the date of purchase. The warranty covers all

defects in material and workmanship insofar as

they are of Campo Equipment CO. LTD,

manufacture. This warranty is limited to the

furnishing of new parts only, in the event the

original part is determined to be defective by

Campo Equipment CO.LTD.

The warranty does not include transportation

costs, labour for inspecting, repairing, or

replacing original parts, or consequential

damages. It also does not cover any damage

because of negligence, accident, misuse, or

abuse. Campo Equipment CO.LTD shall not

be liable for delays caused by defects, for

consequential damages, or for any other

damages, charges, or expenses of any nature.

All parts not manufactured by Campo

Equipment CO.LTD. are warranted insofar as

warranted by the manufacturer of such parts.

SPECIFICATIONS

Model Number ..................................DF1600

Width.......................................31.5" (80.01cm)

Length......................................... 92" (233.68 cm)

Height ......................................58.67"(149.02cm)

Weight ..........................992.00 lbs. (449.96Kg)

Supply panel................23.125”x27” (Rectangular)

Blower Motor ........................3.5Hp (2.57 Kw)

Heated Air Output.......9452 CFM (315.42 m³/min)

Manifold Pressure” W.C….….2.5” LP and 5.6” NG

High pressure switch to be adjusted for manifold

pressure

Minimum/Maximum Supply Pressure “W.C…10/14

Pilot Pressure .....................................3.6” W.C

Maximum BTU Input ........................ 1,600,000

Kcal/h .................................................403193.2

Minimum BTU Input LP............................326289

Kcal/h ...................................................822223

Minimum BTU Input NG...........................324538

Kcal/h .....................................................81782

Required Voltage:

208v to 240v 1Phase or 3 phase

Full Load Amps:

1 Phase 14 amps @ 230v

3Phase 8 amps @230v

This unit is equipped with constant voltage

system. It is activated when voltage is lower

than 208v or higher than 240v.

Minimum 4 X 420lb cylinders are to be used.