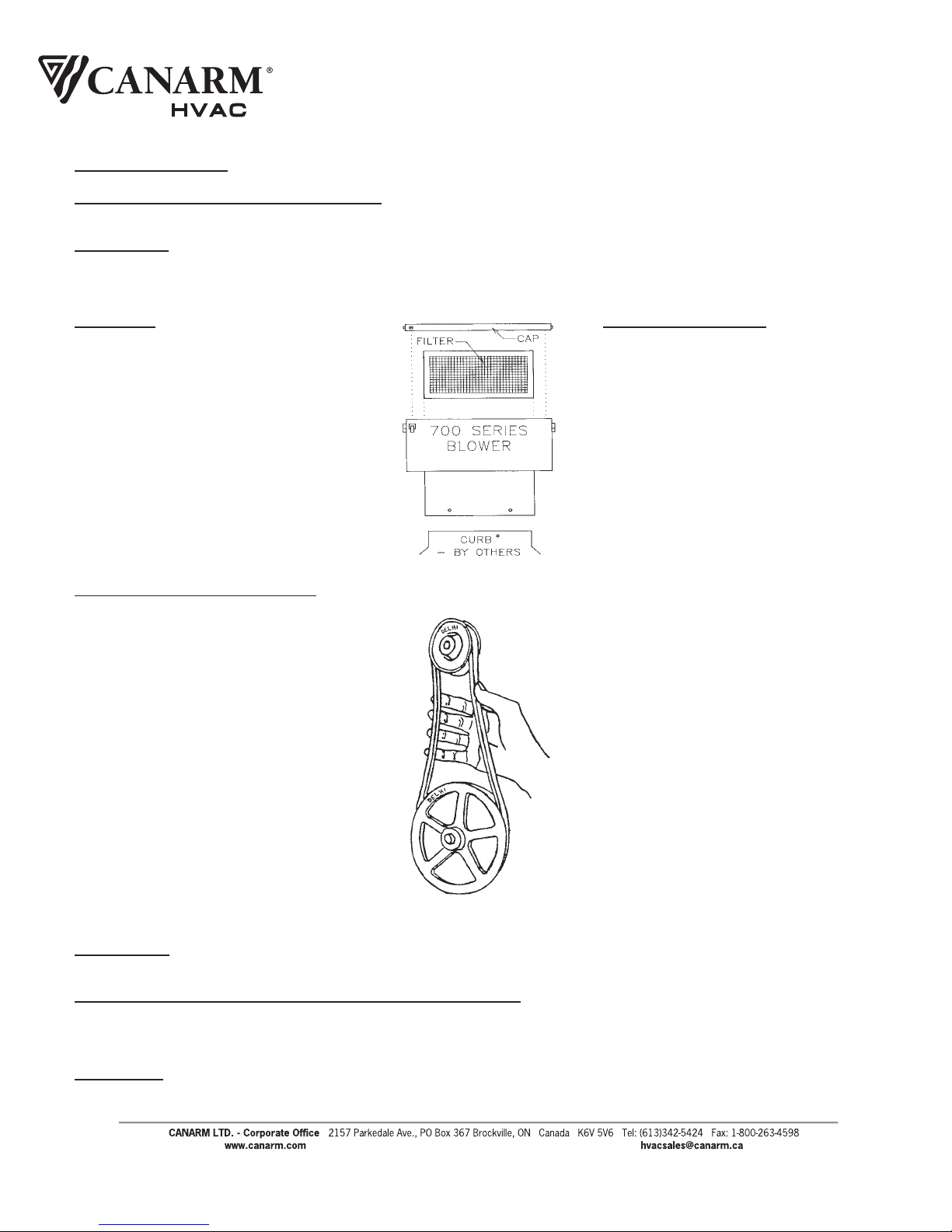

"700" SERIES BLOWER

INSTALLATION AND MAINTENANCE INSTRUCTIONS

RECEIVING INSPECTION

Check for damage or missing parts immediately upon receipt. Ensure that wheel rotates freely.

REPORT ANY DAMAGE PROMPTLY TO CARRIER.

INSTALLATION

ELECTRICAL MOTOR & V-BELT DRIVES

Connect motor in accordance with applicable

codes. Provide properly sized motor overload

protection to protect against electrical faults and

system changes. Confirm proper motor rotation

on start-up.

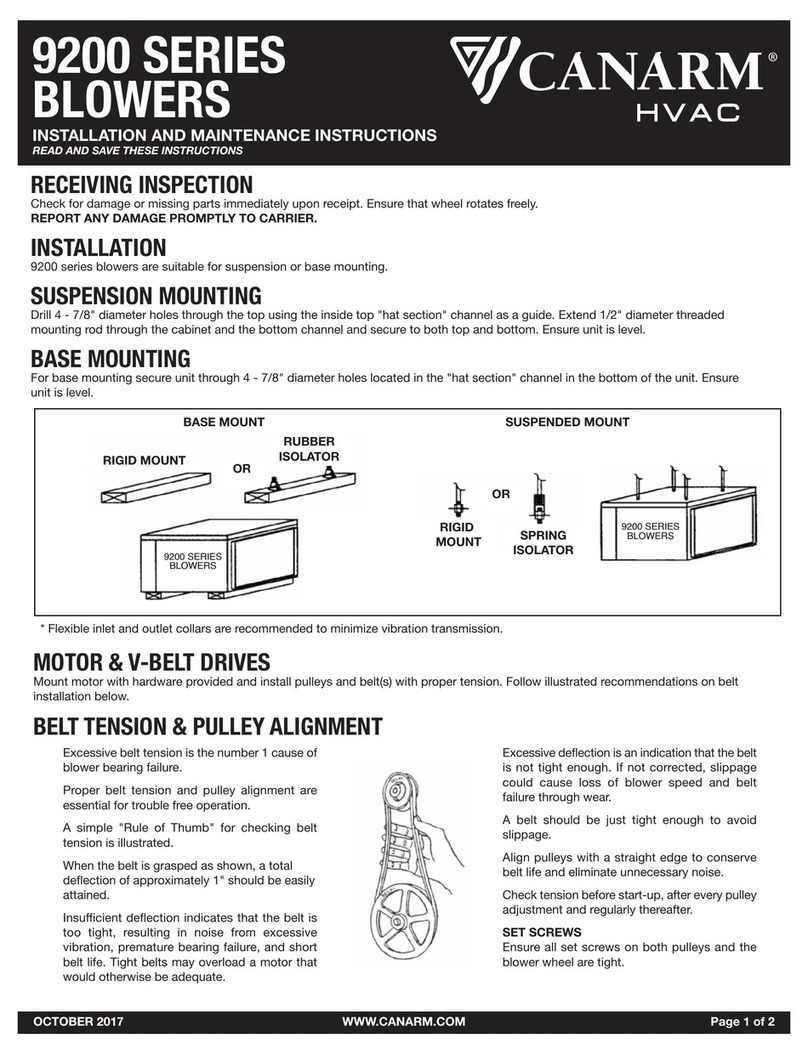

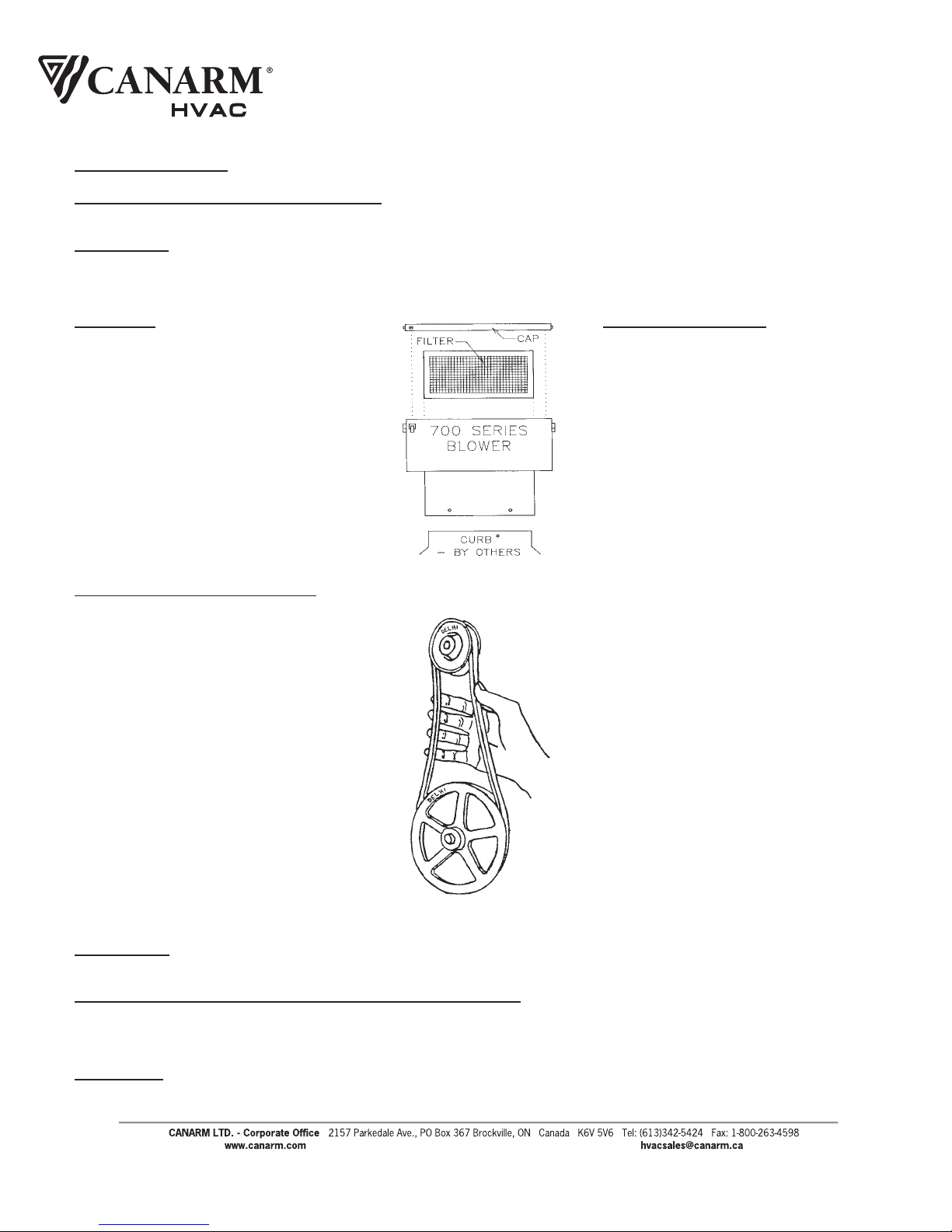

Mount motor with hardware provided and install

pulleys and belt(s) with proper tension. Follow

illustrated recommendations on belt installation

below.

BELT TENSION & PULLEY ALIGNMENT

Excessive belt tension is the number 1 cause of

blower bearing failure.

Excessive deflection is an indication that the belt

is not tight enough. If not corrected, slippage

could cause loss of blower speed and belt failure

through wear.

Proper belt tension and pulley alignment are

essential for trouble free operation.

A belt should be just tight enough to avoid

slippage.

A simple "Rule of Thumb" for checking belt

tension is illustrated.

Align pulleys with a straight edge to conserve belt

life and eliminate unnecessary noise.

When the belt is grasped as shown, a total

deflection of approximately 1" should be easily

attained.

Check tension before start-up, after every pulley

adjustment and regularly thereafter.

Insufficient deflection indicates that the belt is

too tight, resulting in noise from excessive

vibration, premature bearing failure, and short

belt life. Tight belts may overload a motor that

would otherwise be adequate.

Set Screws: Ensure all set screws on both

pulleys and the blower wheel are tight.

MAINTENANCE

LUBRICATION

DELHI INDUSTRIES INC., 523 JAMES ST., DELHI, ONTARIO, CANADA N4B 2Z3 PH:(519)582-2440 FX:(519)582-0581

SE-26-1 AUGUST 1998

Insert bearings with sealed in lubricant are used on all 700 series models. No further lubrication is required.

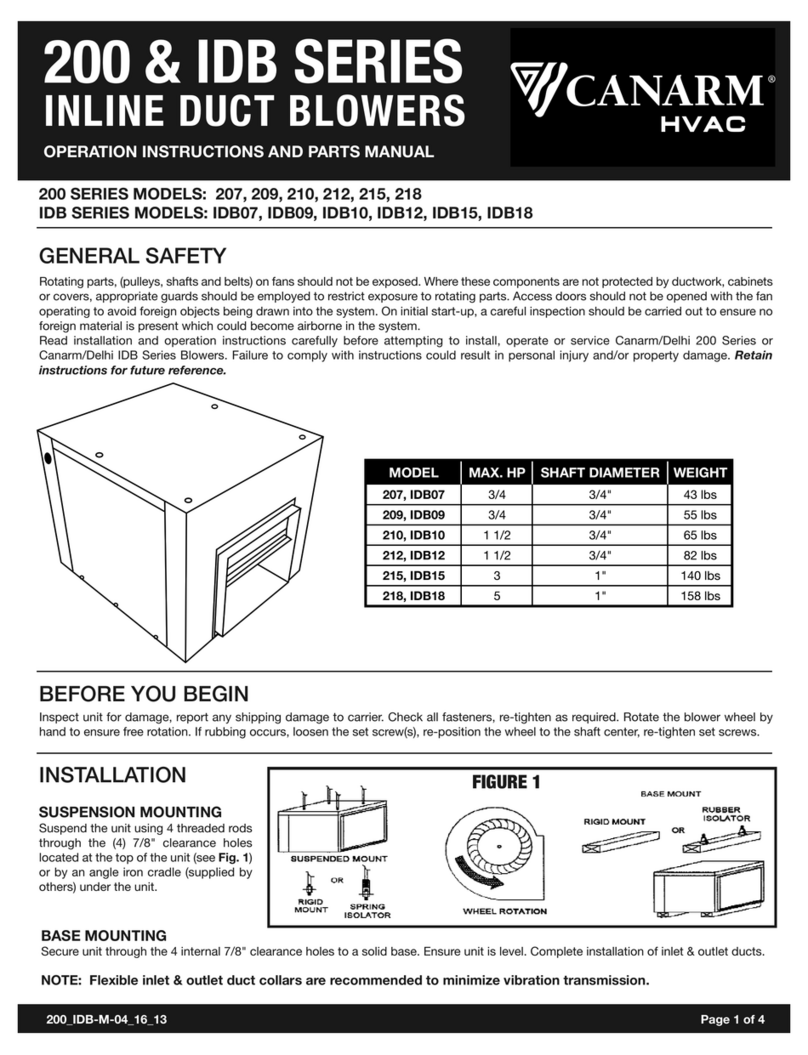

Caulk top of curb. Place unit on curb and secure through 8 - 5/16" diameter holes located around the bottom of the unit. Tighten all set

screws.

Inspect periodically for mounting rigidity. Verify belt for wear and tension and adjust as required. Inspect wheel for any dust accumulation and

clean as indicated.

Caution - do not dislodge balancing clips. Check set screw for tightness.

Inspect filters periodically. Clean and replace as required.