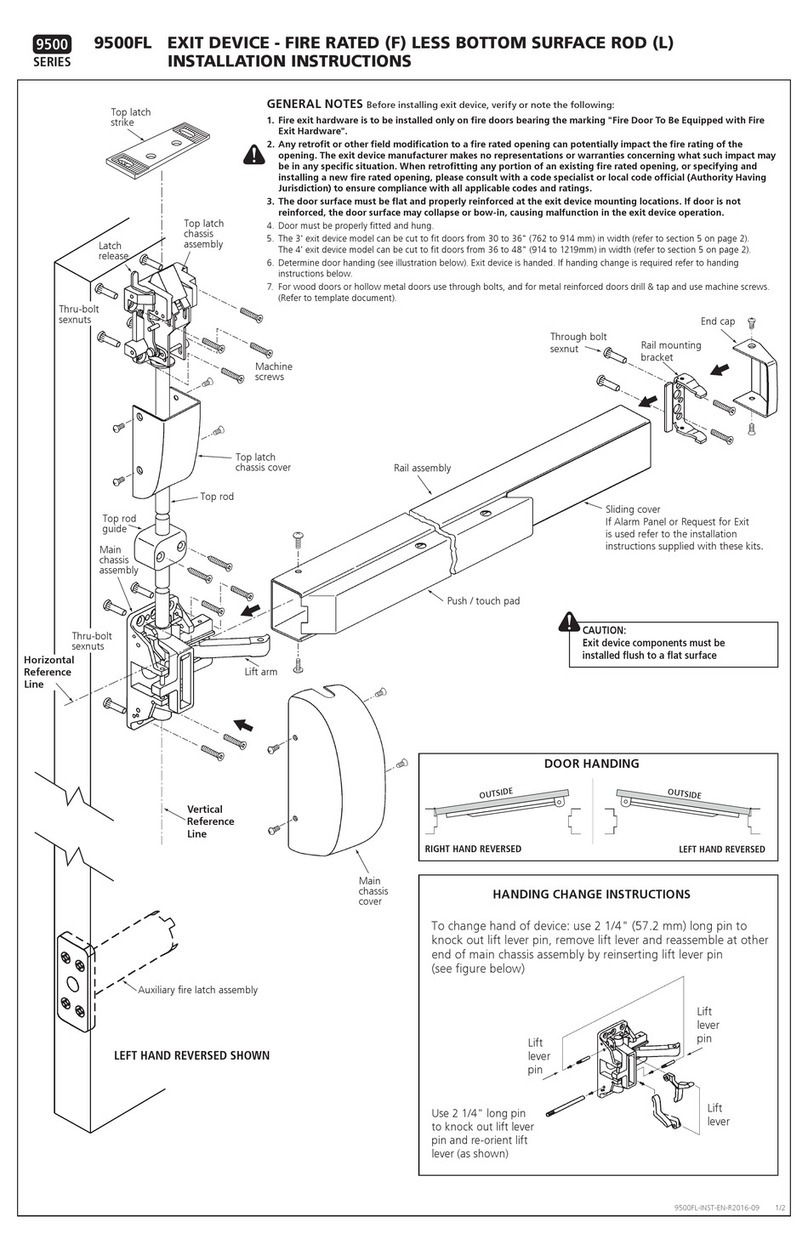

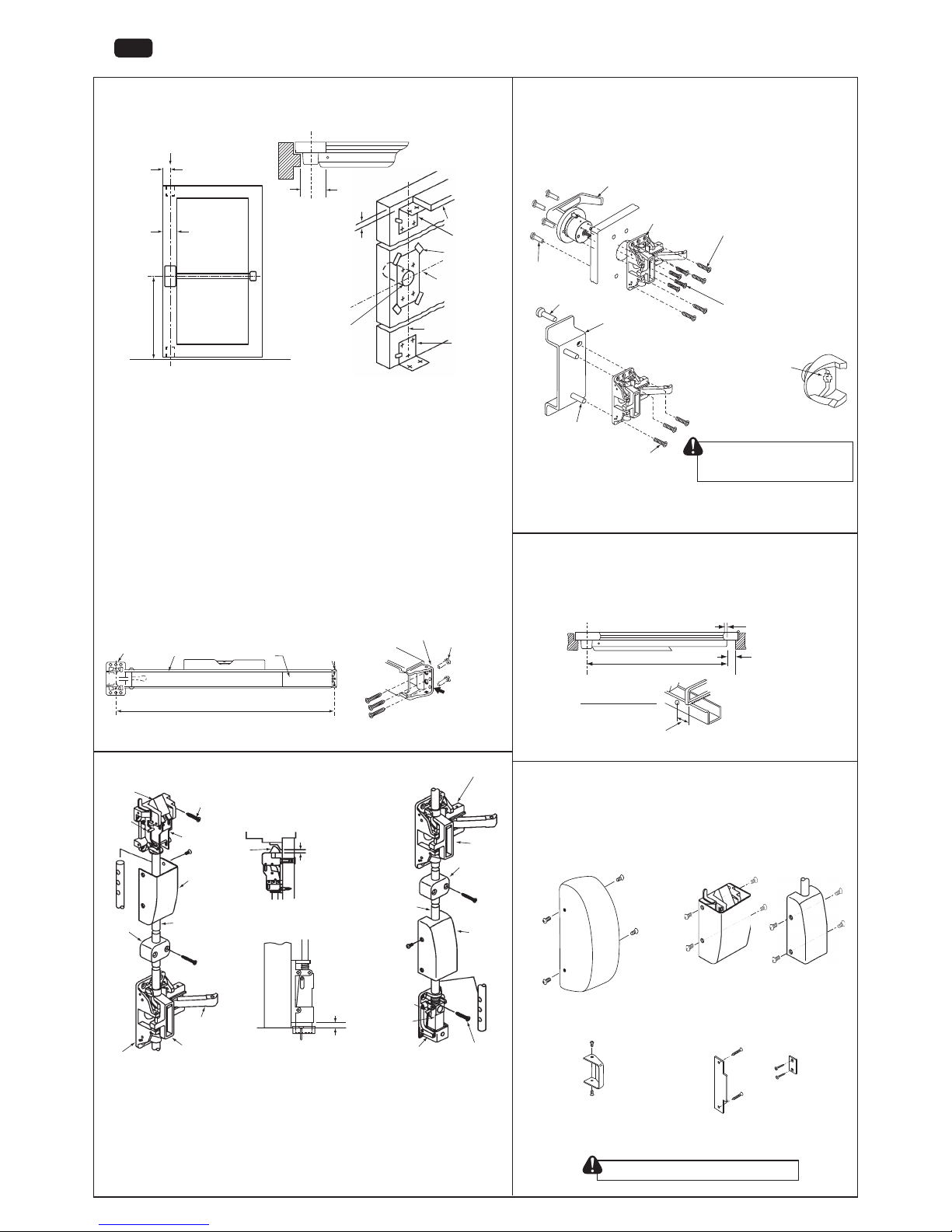

Top latch

chassis

assembly

Retractor

Adjuster

pin

Top

cover

Top rod

Top rod

guide

Lift arm

Main slide

(4) #12 flat

head screws

Top

latch

strike

NOTE: Shim top strike to

obtain 1/8" (3.2 mm) gap

(if required)

1/8" (3.2 mm)

gap required

Adjuster

pin

Retractor

Bottom bolt

chassis assembly

Bottom

rod

Bottom

cover

Bottom

rod

guide

Main slide

1/4"

(6.4 mm)

mortise strike

Main chassis

assembly

Main

chassis

assembly

Previously prepared fire labelled doors must meet the

requirements in note #2 in General Notes on Page 1

1

2

3

4

5

6

7

8, 9

10

10

9500FV-INST-EN-R2016-09 2/2

1. MARK VERTICAL AND HORIZONTAL REFERENCE LINES ON DOOR

Determine the backset based on door lock stile width, and locate the vertical reference line.

a. If lock stile is 4 1/2" (114.3 mm) wide or wider, use 2 3/4" (69.9 mm) backset.

b. If lock stile is less than 4 1/2" (114.3 mm) wide, place the backset at 1/2 of the exposed lock stile width.

2. DOOR PREPARATION AND EXIT DEVICE INSTALLATION

A. Prepare Door, Frame and Floor

1) It is recommended to reinforce the door at the exit device mounting locations and make all required cutouts and holes larger

than 1" (25.4 mm) diameter at the door fabrication shop using dimensions provided in the installation templates.

2) Otherwise, mark the vertical and horizontal reference lines on the door interior surface of the door using provided dimensions.

3) Main Chassis:

a) Position main template on interior door surface by aligning the vertical and horizontal lines and mark the four (4) main

chassis mounting holes.

b) Drill all main chassis mounting holes as per supplied template instructions.

c) If a trim is used, use also the appropriate trim installation template (refer to section 4).

4) Top Latch Chassis and Strike:

a) Position top latch template on interior door surface by aligning the vertical reference line at the indicated dimension from

the frame soffit and mark the four (4) top latch chassis mounting holes on the door and four (4) holes on the frame soffit

for the strike

b) Drill all top latch chassis and strike mounting holes as per supplied template instructions.

5) Bottom Bolt/Latch Chassis and Strike

a) Position bottom latch/bolt template on interior door surface by aligning the vertical reference line at the indicated

dimension from the floor and mark the four (4) bottom latch chassis mounting holes on the door.

b) Drill all bottom bolt/latch chassis mounting holes as per supplied template instructions.

c) Prepare floor cavity for strike dustbox and mark the location of the anchor bolt holes. Drill holes as per template and install

threaded insert with taper pin. Hammer the insert into the hole until flush with or lower than the finished floor.

B. Install Exit Device

1) If no trim is used, install main chassis using four (4) thru-bolts or drill and tap for #10-24 UNC if door is properly reinforced.

2) Level rail assembly and attach the rail mounting bracket to door using two (2) thru-bolts or drill and tap for three (2) #10-24

UNC machine screws if door is properly reinforced and prepped. Use bracket as template.

3) If trim is used refer to section 4.

Backset

Finished Floor

Vertical

Reference Line

Horizontal

Reference Line

41"

(1041 mm)

Frame Door Stop

Top Chassis

Template

Tape

Horizontal Reference

Line

Vertical Reference Line

stop thickness

2 1/8" (54 mm) ø

bore when knob

or lever trim is used

Bottom Chassis

Template

On finished floor

Soffit

Lock

stile

3. INSTALL TOP & BOTTOM CHASSIS AND STRIKES

1. Mount top latch chassis on door using four (4) machine screws or machine screws with thru-bolt sexnuts.

2. Mount top strike at location determined in section 2, secure with two (2) machine screws. (refer to template)

3. Screw top rod (longer rod) into main slide (see above left illustration).

4. Slide guide onto top rod and insert rod into top latch chassis, insert adjuster pin through retractor and middle hole in rod.

Use the appropriate hole in rod to ensure proper latch engagement with strike. Adjust strike position as required then

fasten screws. If shorter rod is required cut rod to required length and drill a 1/8" (3.2 mm) dia. hole through the rod.

5. Ensure top latch engages and operates properly with strike, adjust position if required. Secure with two additional screws.

6. Mount bottom bolt chassis in same manner as top chassis (see above right illustration).

7. Repeat steps 3 and 4 to install the bottom rod into the bottom bolt chassis.

8. Install bottom latch strike on the floor, refer to illustration above, instructions in Section 2 and on bottom bolt template.

9. Verify that bottom bolt engages properly with strike on the floor.

10. Fasten rod guides at mid-length of rods. Pre-drill 1/8" (3 mm) holes for wood screws, or drill & tap for # 10-24 UNC

machine screws.

Lever or Knob Trim

(9500TL or 9500TK)

Thru-bolt

sexnut

Pull Trim

(9500TPDT)

Ensure that the

spindle does not

extend past the

cam surface

4. INSTALL TRIM

a) Refer to applicable trim template and installation instructions: drill/bore holes on door exterior

surface as per trim installation instructions.

b) Use mounting hardware supplied with the exit device and with applicable trim.

c) Do not over-torque trim mounting screws, and ensure door surface is not bowed-in.

CAUTION: Over-torquing may cause exit device to jam.

d) Verify that the trim operation retracts the exit device latch.

TYPICAL TRIM INSTALLATIONS

4

For escutcheon trim (9500TE) installations, refer to the template and installation instructions

supplied with the applicable trim.

NOTE: Vertical rods must be properly aligned to eliminate any friction or binding that may interfere with the

exit device smooth operation

Door

Attach pull trim

and chassis to door

using hardware

supplied with the

pull trim

Trim and chassis

mounting screws

Main

chassis

A

A

A

A

B

B

B

B

Main Chassis

mounting

hardware

[ 4-screws (A) ]

Trim

mounting

hardware

[ 4-screws (B) ]

Thru-bolt

sexnut

Thru-bolt

sexnut

Don't cut closer than 1 3/4"(45 mm) from lower pivot

(remove sliding cover to locate pivot)

minimum

1/2" (12.7 mm)

X

Y

minimum

1 3/4" (45 mm)

For door with stile, cut off must leave

minimum 1/2" (12.7 mm) overlap with rail

Backset or vertical

Reference Line

5. MODIFY RAIL

a) Confirm length of device and determine if rail cutting is required.

b) Determine length 'X' by subtracting 1 3/4" (45 mm) from 'Y'. Mark cut-off point on rail and sliding

cover and cut-off.

c) Deburr and remove all sharp edges after cutting and install as per section 2.

CUT OFF & DEBURR

Attach covers to top and

bottom chassis with

(4) four screws each

(c)

On doors and frames that have been prepared for

use with strikes and latches, install the appropriate

filler plates using flat head wood or machine screws

Latch Filler

Plate

Strike Filler

Plate

(d)

Attach cover to main chassis

assembly with four (4)

flat head machine screws

Attach end cap to rail mounting

bracket with two (2)

flat head machine screws

(a)

(b) (e)

6. INSTALL COVERS

a) Attach the main chassis cover to the main chassis using supplied machine screws.

b) Attach the rail end cap to the rail mounting bracket using supplied machine screws.

c) Attach the the top and bottom latch chassis covers using supplied machine screws.

d) If required, fill existing frame strike location on door frame with the strike filler plate using

supplied mounting screws.

e) If required, fill existing latch faceplate location on door edge with the latch filler plate using

supplied mounting screws.

Four (4) machine

screws or

thru-bolts with

sexnuts

Four (4) machine

screws or

thru-bolts with

sexnuts

4

Exposed

stile width

36" model = 30 11/16" (780 mm)

48" model = 42 11/16" (1088 mm)

REFERENCE

Push bracket

tightly against

rail assembly

Level

Rail

Assembly

Main Chassis

Rail

Mounting

Bracket

Sliding Cover

or Alarm Panel

Attach rail mounting bracket

to door with two (3) machine

screws or with two (2)

thru-bolts and sexnuts

(if required)

#10-24

Sexnut

For Fire labelled doors: it is recommended

that all cutouts and holes be done at the

fabrication shop, as field modifications

may impact the door fire rating

9500FV EXIT DEVICE - FIRE RATED (F) SURFACE VERTICAL RODS (V)

INSTALLATION INSTRUCTIONS

9500

SERIES