Cane Creek Cycling Components • 355 Cane Creek Road • Fletcher, NC 28732

ph:

828.684.3551 • fax: 828.684.1057 • web: www.canecreek.com • e-mail: [email protected]Hooked tool Needle-nose pliers

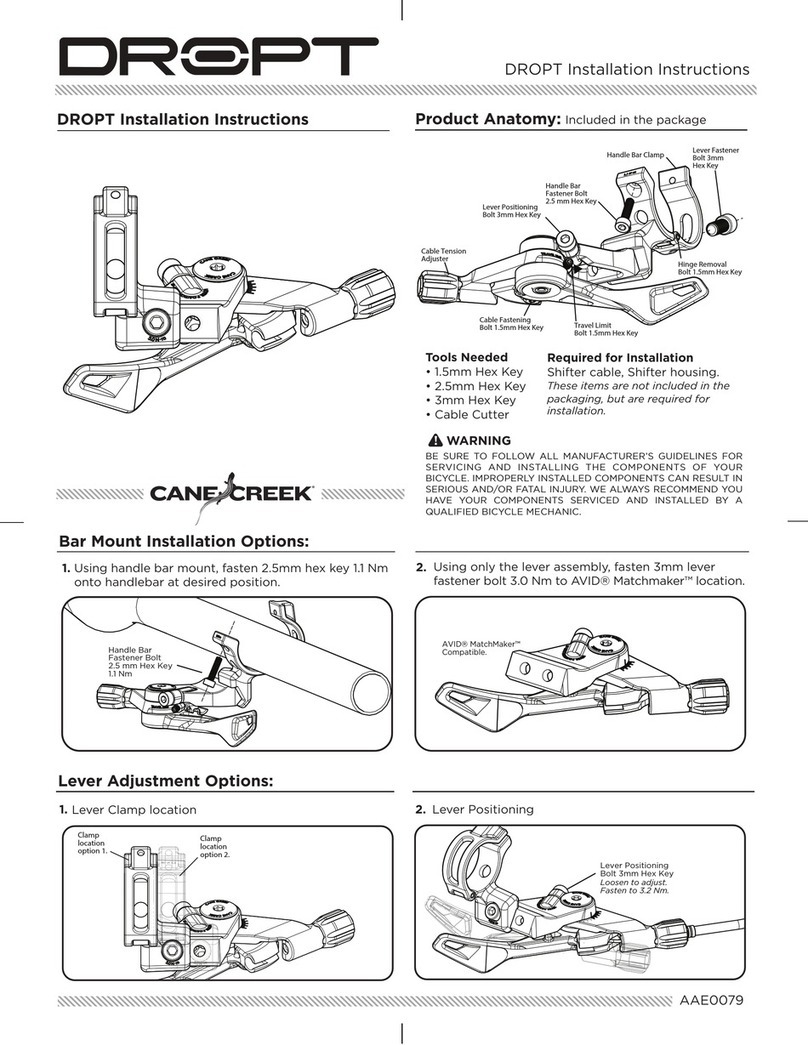

Required Tools:

8mm socket wrench

section B.Otherwise,the shock is ready to reassemble.

8.Reinstall the lock ring on the piston shaft.The rod wiper end should go onto the shaft first.

9.Reinstall the seal bushing on the piston shaft.Use the assembly collar (Figure 10) supplied in the seal kit to

simplify this step.Place the assembly collar into the open end of the piston shaft and slide the seal bushing

(larger end first) down over the collar into place on the shaft.Be careful not to cut or pinch the seals while

reinstalling the seal bushing.Once the seal bushing is in place remove the assembly collar.

10.Place the compression shim on the step in the compression rod.It should sit flat.Now place the slotted

end of the compression cylinder on the shim.

11.Screw the piston back onto the shaft being careful not to disturb the compression cylinder and compres-

sion shim.Tighten the piston using the spanner wrench or socket wrench with special spanner head.Apply

Cane Creek De-friction Lube to the interior of the large cylinder.Hold the glide ring in place on the piston and

carefully slide the large cylinder down over the piston.

12.Remove the piston end of the shock from the vice,and place the valve end in the vice again.Slide the seal

bushing down the shaft and into the open end of the large cylinder as far as it will go.Now slide the lock ring

over the seal bushing and screw it onto the large cylinder.The lock ring should capture the wire ring at the

end of the threads leaving half of it exposed.Be sure that the wire ring is evenly in place all the way around

the shock.

13.Aligntheeyeletsbyturning the piston shaft.InflatetheAD-12withahand shock pump to about150psi.

Submerge it in water to see if any bubbles come from the shock indicating leaks.If a leak is detected,disas-

semble the shock again and check the appropriate seal for cuts or dirt.If there are no leaks,the shock can be

remounted on the bike and inflated to riding pressure.It may be difficult to compress the shock the first time

since the negative air spring chamber has not been charged.It is charged when the shock is compressed

about 1/2 inch (13 mm).Once it is filled the shock will function normally.

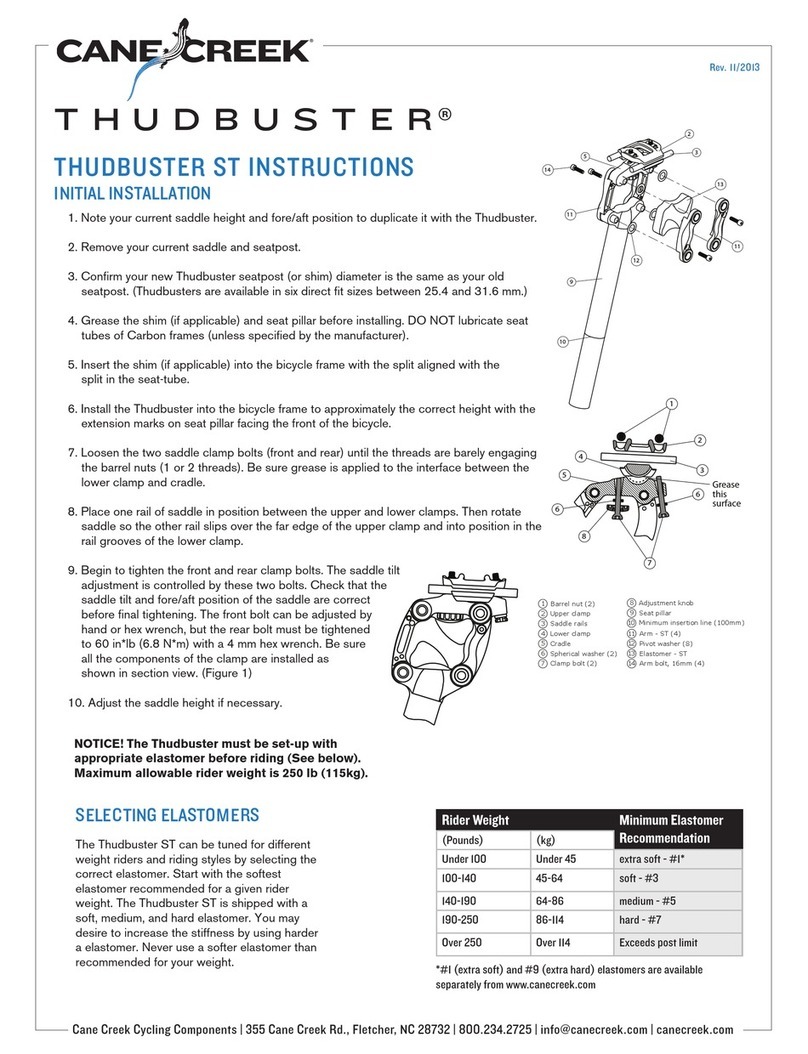

Section B:Tuning Modifications

The AD-12 Rear Shock is designed to be used

with a wide variety of bike frames.The shocks

are built and tuned at the factory for a

particular bike.If the factory settings are not

appropriate for your preferences or riding

abilities you can change the factory setting

relatively easily.There are four different factors

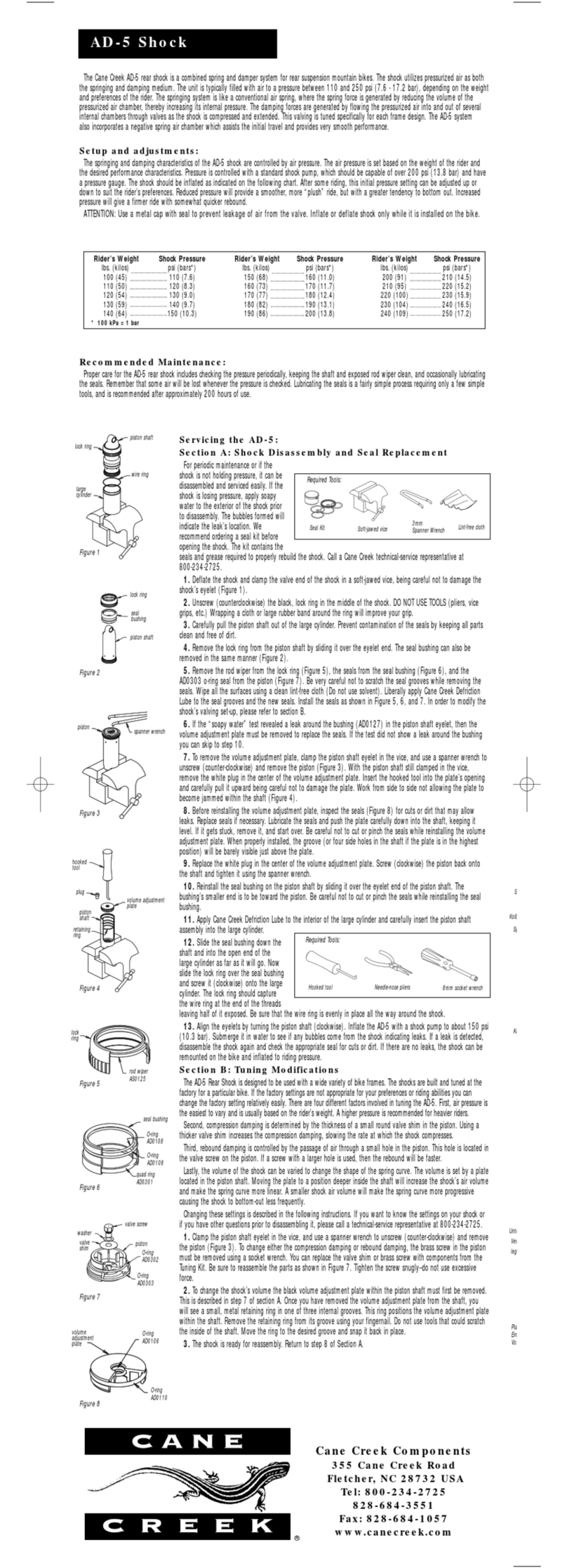

involvedin tuning the AD-12.Air pressureistheeasiesttovary and is usually based on the rider’s weight.

Compression and rebound damping can be set using the adjuster knobs as previously discussed.And,the

volume of the shock can be varied to change the shape of the spring curve.The volume is set by the volume

adjustment plate located in the piston shaft.Moving the plate to a position deeper inside the shaft will

increase the shock’s air volume and make the spring curve more linear.A smaller shock air volume will make

the spring curve more progressive causing the shock to bottom-out less frequently.Changing the air volume

setting is described in the following instructions.If you want to know the setting on your shock or if you have

other questions prior to disassembling it,please call a technical service representative at 800-234-2725.

1.To change the shock’s volume(or repair a leak in the piston shaft eyelet bushing,AD0127)the black,volume

adjustment plate within the piston shaft must first be removed.With the piston shaft still clamped in the vice,remove the aluminum

rebound rod and compression rod by pulling them up and out of the black plate (Using a dry lint free cloth will improve your grip.Do not

use tools that will damage the surface).They will probably come out together.(Figure 7)

2.Insertthe hooked tool into the volumeadjustment plate’sopening and carefullypullitupward,being careful not to damage theplate.

Work from side to side not allowing the plate to become jammed within the shaft.Once you have removed the plate,you will find the

rebound ramp and compression ramp loose inside the piston shaft.They were attached to the rods you removed in step 1.If you are simply

repairing a leak,you can replace the seals on the plate as shown in figure 8,and move to step 4.

3.A small,metal retaining ring will be visible in one of three internal grooves of the piston shaft.This ring positions the plate within the

shaft.Remove the retaining ring from its groove using your fingernail.Do not use tools that could scratch the inside of the shaft.Movethe

ring to the desired groove and snap it back in place.

4.Slide the rebound rod out of the compression rod if they are not already apart,and check the o-ring seal on the rebound rod.You can

replace it with AD0125 from the seal kit.

5.Nest the rebound ramp inside the compression ramp and insert the blunt end of the rebound rod into the hole.If it does not stay

attached,a slight amount of grease on the end of the rebound rod will help keep things together.(Figure 9)

6.Carefully insert the rebound rod assembly into the black ramp housing in the bottom of the piston shaft.The ramped side of the re-

bound and compression ramps should face toward the external adjuster knobs.Both adjuster knobs should be backed out 2 - 3 turns from

the full-in position when reassembling the shock.Note:the adjuster knobs should never be removed from the piston shaft.Doing so

will damage them.

7.Before reinstalling the volume adjustment plate inspect the seals for cuts or dirt that may allow leaks.Lubricate the seals and push the

platecarefullydownintothe shaft,keepingit level (Be careful not tocutorpinchthesealswhilereinstallingthe volume adjustmentplate).

The sharp end of the rebound rod will protrude loosely through the hole in the center of the plate.If the plate gets stuck remove the

rebound rod,plate,and ramps;and start over.When properly installed,the groove (or four side holes in the shaft if the plate is in the highest

position) will be barely visible just above the plate.

8.Slide the compression rod (shiny end up) down over the rebound rod and through the hole in the plate.It will be a little tight going past

the seals.Be careful not to cut them in the process.

9.The shock is readyfor re-assembly.Returnto step8ofSection A.

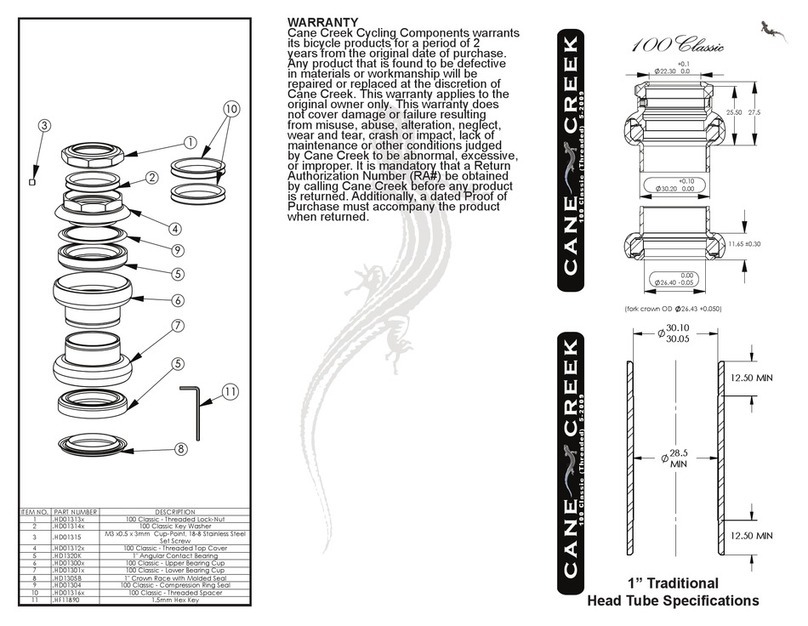

WARRANTY

Cane Creek Cycling Components warrants its bicycle components for a period of two years from the original date of purchase. Any

Component that is found to be defective in materials or workmanship will be repaired or replaced at the discretion of Cane Creek. This

warranty applies to the original owneronly. This warranty does not coverdamage or failure resultingfrommisuse,abuse,alteration,

neglect,wear and tear,crash or impact,lack of maintenance or other conditions judged by Cane Creek to be abnormal,excessive, or

improper. Itis mandatorythata ReturnAuthorization Number (RA#)isobtainedbycalling Cane Creek beforeanyproduct is returned.

Additionally,a dated Proof of Purchase must accompany the product when returned. (Revised 5.12.2003)

volume

adjustment

late

comp.

ramp

reboun

ramp

comp.

ro

reboun

ro

iston

shaft

retaining

ring

Figure7

o-ringsea

AD012

hooked

tool

Figure8

o-ringsea

D0110

o-ringseal

D0106

volume

adjustmen

plate

Figure9

rebound

rod

rebound

ramp

compression

ramp

seal

bushing

assembly

collar

iston

shaft

lock

ring

Figure10