Cutting Steerer Tube:

Cut the steerer tube using a good quality

hacksaw and an appropriate guide. To ensure

a clean cut always use a sharp, ne toothed

hacksaw blade. Be sure to le and de-burr the

freshly cut edge before assembly. It can be helpful

when cutting threaded steerers to thread the

headset top cover or a threading die onto the fork

before cutting. Once cut, simply un-thread the top

cover or die to clean-up the threads.

Steerer Tube Length

For the safe and proper installation of a

threaded headset system it is imperative that the

top of the fork’s steerer tube does not bottom out

on the locknut when fully assembled. In order to

achieve this it may be necessary to cut the steerer

tube or insert additional spacers between the top

cover and locknut. To prevent damage to the

aluminum locknut, ensure that the locknut threads

on at least 3 full revolutions before tightening. If it

does not, the steerer tube is too short or there are

too many spacers in the assembly.

The following formula may be used to

determine the proper steerer tube length:

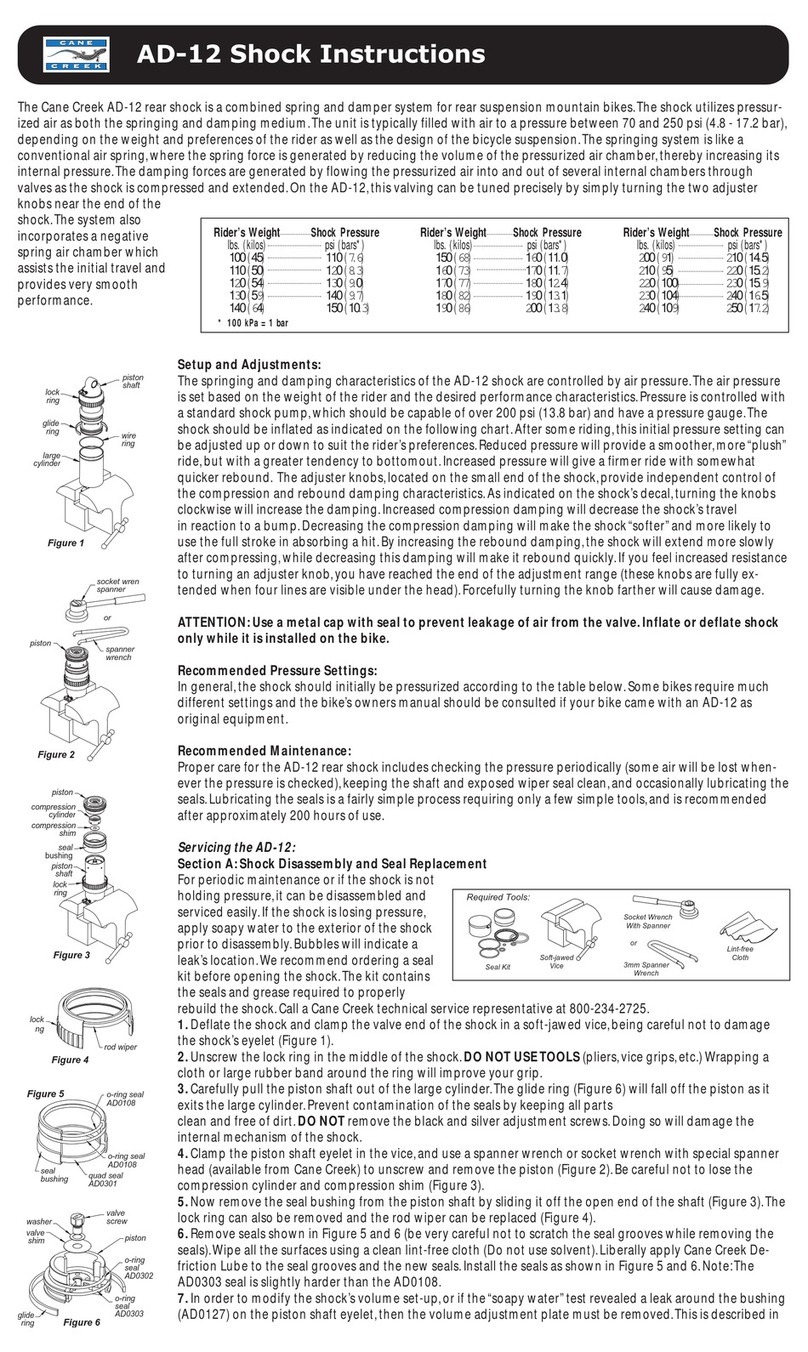

Installing the Bearing Cups:

Press the upper and lower bearing cups

into the head tube using a good quality headset

press. It is often easier and more precise to press

in one cup at a time.

The 100 headsets are equipped with drop-

in bearings for easy replacement and tolerance to

frame/fork misalignment. When pressing the cups

into the frame the bearings should be removed.

Cup installation is best done using Cane Creek

headset installation tools to press directly on the

bearing seats. These tools are designed to ensure

the safe installation of all Cane Creek Headsets

and are available through your local Cane Creek

dealer.

Installing the Crown Race:

Press the fork crown race onto the fork

with an appropriate crown race installation tool until

the bottom of the race is ush with the fork crown.

This should be a press t.

Frame and Fork Preparation:

Use head tube reaming and facing tools

to prepare the top and bottom of the frame’s head

tube. (Be sure to use the correct reamer diameter

corresponding to the headset being installed.)

Use a crown race cutting tool to turn and

face the crown race seat of the fork, again being

sure to use the correct diameter tool.

Adjusting the Headset Assembly:

With the headset installed and assembled

insert the fork into the frame. Apply a quality water-

proof grease to the fork threads and thread the

top cover onto the fork until it makes contact with

the upper bearing. Next assemble the key-washer

and any necessary spacers and then thread-on the

lock nut but do not tighten. Carefully tighten the

top cover until all play is taken out of the headset

assembly, this should require very little force. To

lock this adjustment in place it is necessary to

rmly tighten the locknut against the top cover. Do

this by holding the top cover in place with a 32mm

wrench while tightening the locknut with another

32mm wrench. Check for play by rmly holding the

front brake and rocking the bike backwards and

forwards. With the headset properly adjusted there

should be no play in the assembly and the fork

should rotate easily without binding.

ST Length = Lower Stack Height(11.65mm)

+ Head Tube Length + Upper Stack Height

(25.5mm) + Height of Spacers(if any) - 2mm

Notes:

If the headset will not tighten properly check to1.

be sure your steerer tube has enough threads

to allow the top cover to fully contact the upper

bearing.

If there are problems threading the top cover2.

and locknut onto the fork, ensure that the

threads are clean and un-damaged.

If the headset binds, be sure that the preload3.

adjustment is not too tight. If binding occurs

even with proper adjustment this could be a sign

that the frame and/or fork needs to be reemed

and faced.

After an initial break-in period it may be 4.

necessary to repeat this process. As with all

threaded headset systems regular checks

should be made to check the headset for proper

adjustment.

Installation and removal of the upper seal:

Cane Creek 100 Classic headsets are

equipped with a special rubber seal above the

upper bearing to help guard against contamination.

On the threaded headset this seal is press-t onto

the top cover. If it becomes necessary to remove

or replace this seal the process is fairly easy.

To remove the seal use a small, thin, at-

bladed screw-driver or similar instrument to pry the

seal off of its seat. This should not take very much

force.

To install the seal, nd a cylinder with an

inside diameter very slightly larger than 29.1mm (a

socket or 1-1/8” crown race works nicely). Place

Set-Screw Adjustment:

The 100 Classic is equipped with a key-

washer that goes between the top cover and the

locknut. The purpose of this washer is to separate

the rotation of the top cover and locknut. The “key”

is formed by the small set-screw installed in the

washer and is designed to interface with the small

slot machined into the threads of most steerer

tubes.

These slots are not necessarily

standardized so the set-screw conguration allows

the user to adjust the depth of the “key” to t his or

her particular fork. Also, if the fork is not equipped

with said slot, the key may be completely removed

from the washer.

To adjust the key, use the included 1.5mm

hex wrench to move the set-screw in and out of

the washer. The screw should be adjusted as far

inwards as possible while still allowing the washer

to ride freely up and down the steerer tube. The

set-screw should also not be adjusted so far out

that the key-washer assembly will not nest inside

the recess on the top of the top cover.

the seal over the conical face on the top cover and

ensure that the concave face of the seal faces

towards the bearing. Next, place the cylinder

over the seal and press rmly with hand pressure

only. There should be a slight popping or scraping

noise as the seal slides over the top cover. Check

to ensure that the seal is seated correctly and re-

assemble the headset.