4

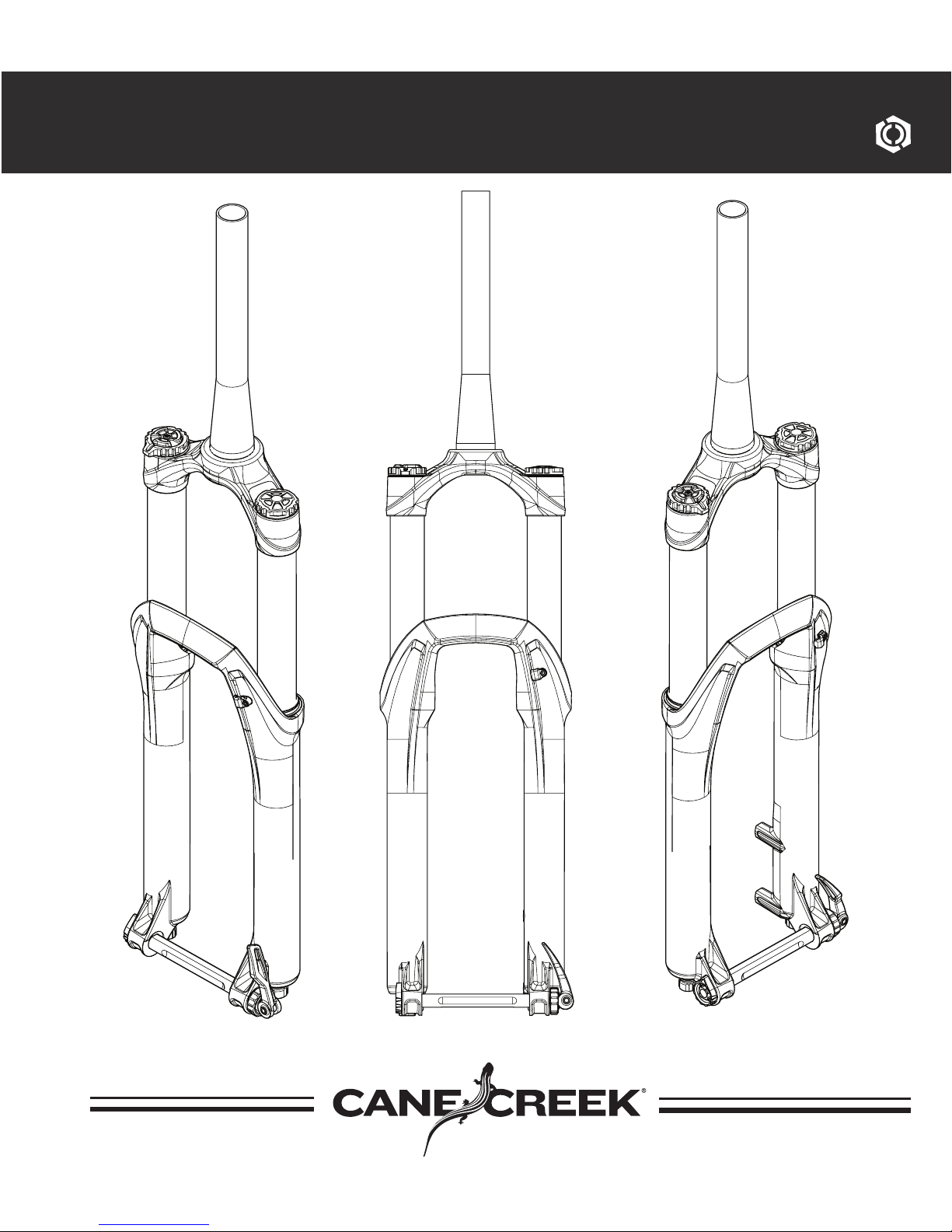

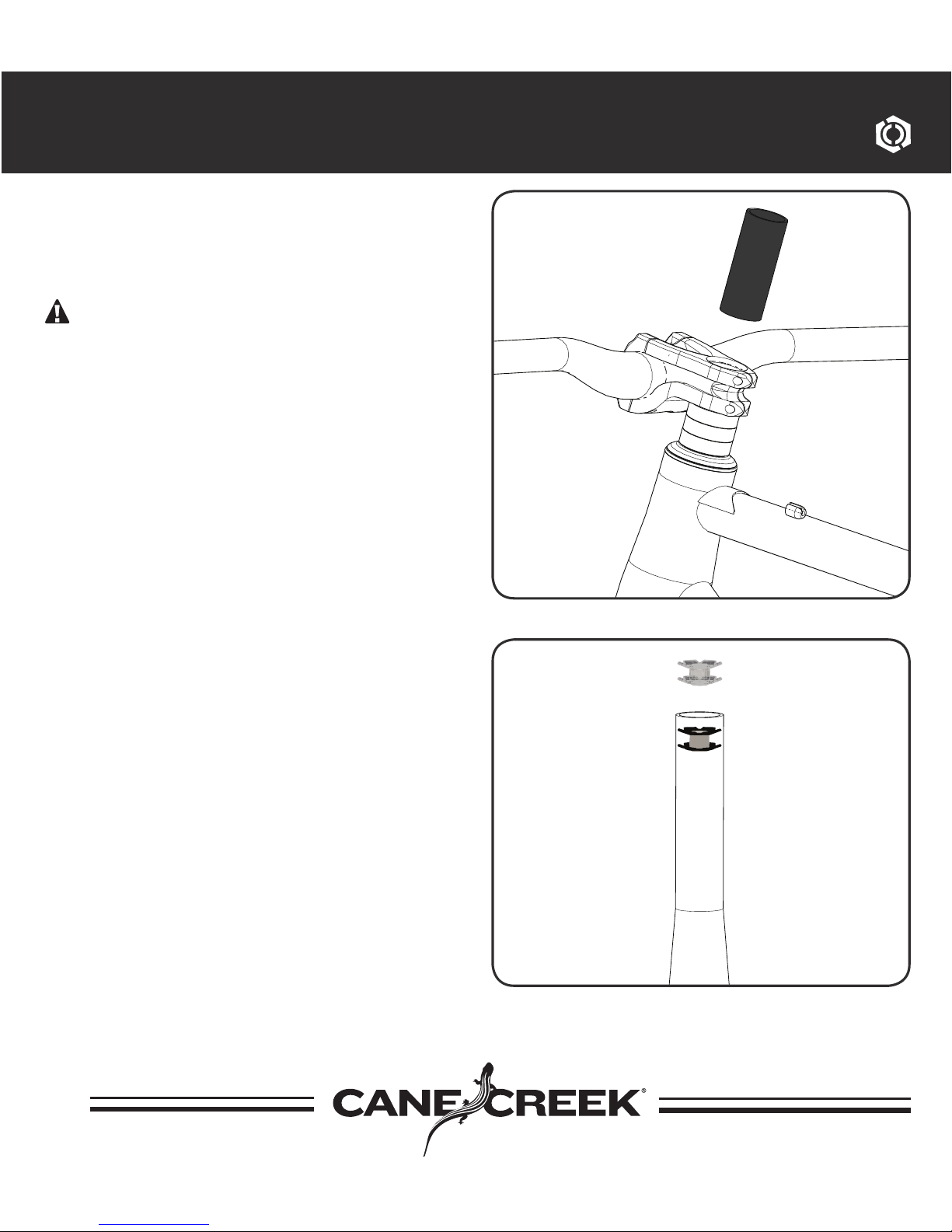

The fork is an important part of your

bicycle. Before installing and using

your new front fork, carefully read this

owner’s manual to learn the correct

installation and adjustment procedures

of this fork.

Warning

Improperly installed and/or adjusted

forks can cause serious harm or death

and may severely damage your bicycle.

Warning

A broken or malfunctioning fork may

cause loss of vehicle control and result

in SERIOUS INJURY OR DEATH. If the

fork ever loses oil, air or makes

unusual noises, stop riding and have

the fork inspected by a Cane Creek

Authorized Suspension Service Center

or call the Cane Creek Customer

Service Team.

Warning

Modification, improper service or use

of aftermarket replacement parts voids

the warranty and may cause the fork to

malfunction, resulting in loss of vehicle

Safety Warnings

control and SERIOUS INJURY OR

DEATH. Do not modify your bike frame

or fork. Use only genuine Cane Creek

Helm parts.

Follow service maintenance

recommendations. Fork service

should be performed by Cane Creek

Cycling Components or a Cane Creek

Authorized Suspension Service Center.

Visit www.canecreek.com or contact

us at 800-234-2725 to locate a Cane

Creek Authorized Suspension

Service Center.