5

2270 Fiber Optic Modem

3.5.2 DS1 / T1 Model -T1 ......................................................................................... 30

3.6 TTL/BNC Interface Model -BN .................................................................. 30

3.8 ....................Programmable Buffered Interface Model P53 32

3.8.1 Generic Interface.............................................................................................. 36

3.8.2 External Station ............................................................................................... 37

3.8.3 Internal............................................................................................................. 38

3.8.4 External ........................................................................................................... 39

3.8.5 DTE Adapter ................................................................................................... 40

3.8.6 Legacy Adapter ............................................................................................... 41

3.9 High-Speed RS-422/Mil-Std 188-114C Interfaces ...................................... 42

3.9.1 Model -TW ....................................................................................................... 43

3.9.2 Model -TW8 ..................................................................................................... 44

3.9.3 Model -T22 ....................................................................................................... 44

3.9.4 Model -T88 ....................................................................................................... 44

3.9.5 Model -D22....................................................................................................... 44

3.9.6 Model -D88....................................................................................................... 44

3.10 Interface Reconfiguration .......................................................................... 46

3.11 Standalone Reconfiguration ....................................................................... 46

Chapter 4 - Modem Operation ................................................................... 47

4.1 Modem Operation ........................................................................................ 47

4.2 Fiber Optics................................................................................................... 47

4.3 Transmit Section ........................................................................................... 48

4.4 Receive Section ............................................................................................ 48

4.5 Full Rate Agility ............................................................................................ 48

4.6 Bit Count Integrity ........................................................................................ 49

4.7 Duty Cycle Tolerance ................................................................................... 49

4.8 Control Signals .............................................................................................. 49

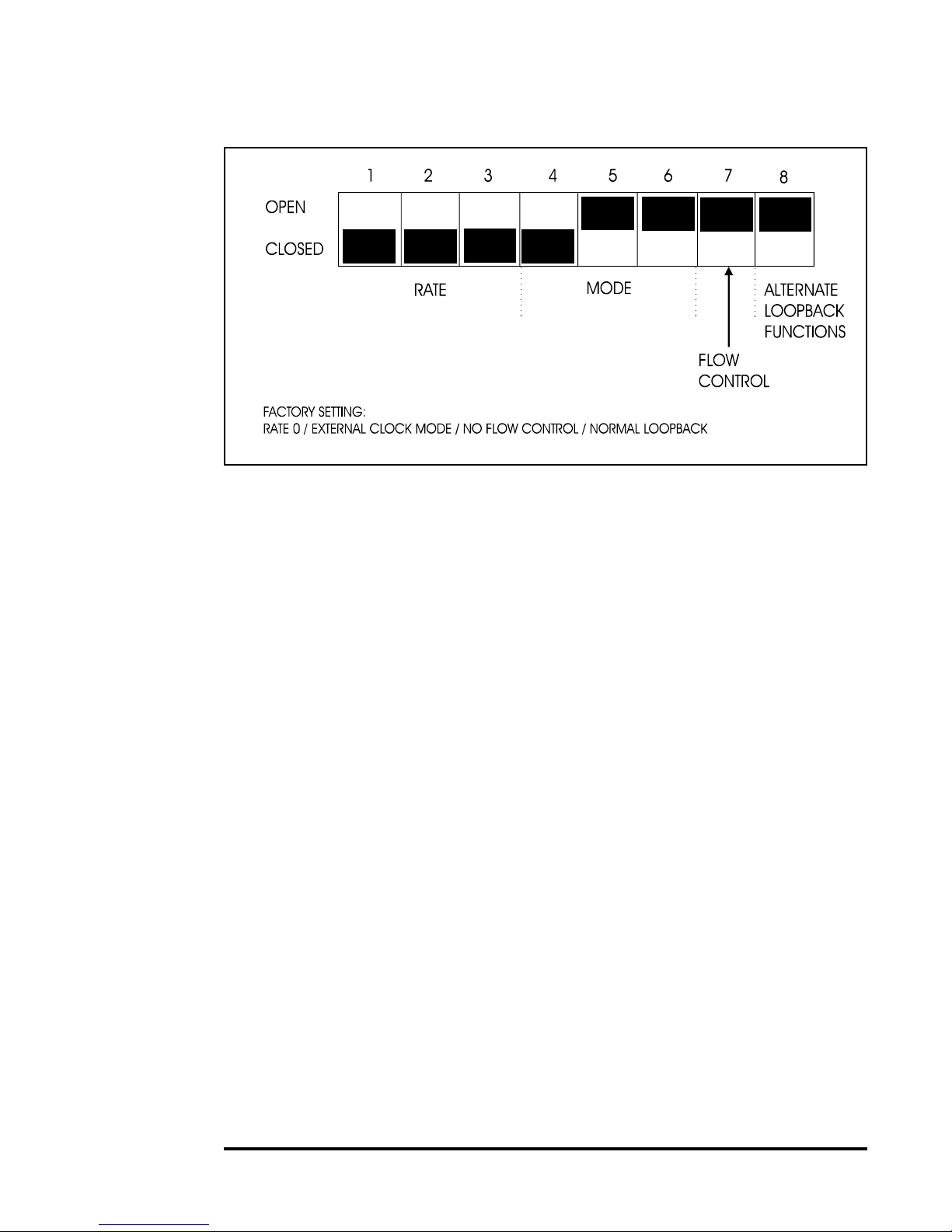

4.8.1 Flow Control ..................................................................................................... 50

Chapter 5 - Troubleshooting ......................................................................... 51

5.1 Diagnostic Procedures.................................................................................. 51

5.2 System Test................................................................................................... 51

5.2.1 Local Loopback Test ........................................................................................ 53

5.2.2 Remote Loopback Test..................................................................................... 54

5.2.3 System Loopback Test ..................................................................................... 55

Chapter 6 - Diagnostic Procedures ............................................................ 56

6.1 2270/2201 Diagnostic Procedures................................................................ 56

6.2 System Test Diagnostic Procedure .............................................................. 56

Chapter 7 - Specifications ............................................................................. 58

7.1 Diagnostic Indicators and Controls ............................................................. 58

7.2 Optical Interface ........................................................................................... 58

7.3 System Electrical .......................................................................................... 59

7.4 Physical Dimensions ..................................................................................... 59

7.5 2270 Fiber Optic Modem Configurations .................................................... 60

Appendix A ..................................................................................................... 61

A.1 Customer Service Department Repair ....................................................... 61

Warranty .............................................................................................................. 61

A.2 Return Policy................................................................................................ 61