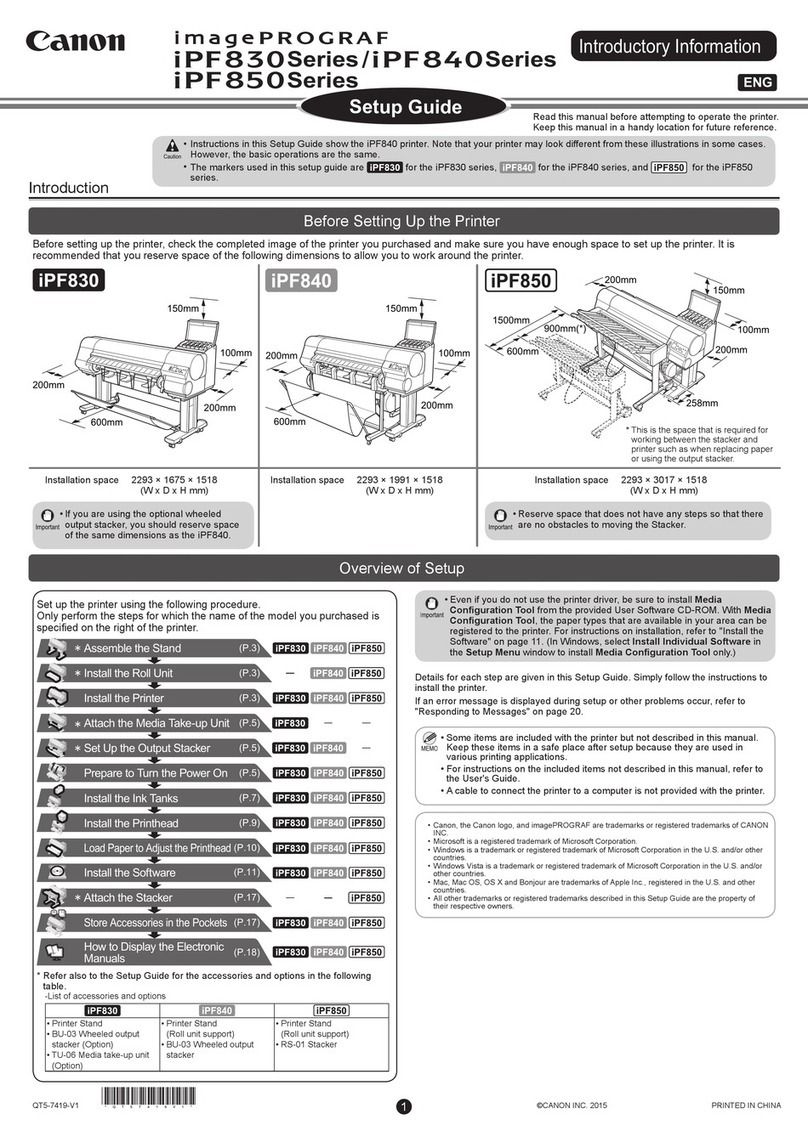

Remedy for Image Trouble in iPR1135 Series

■ Uneven Densit

Ima

e (Shock Ima

e)

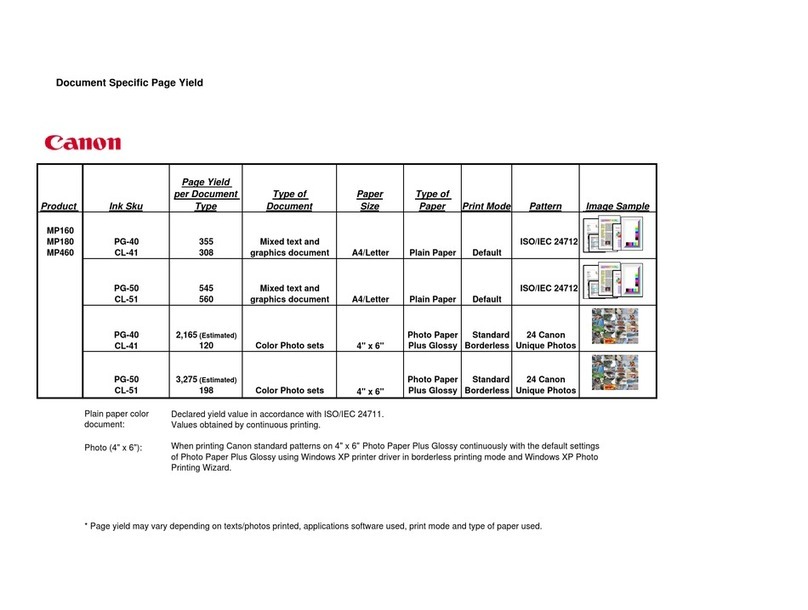

Paper type

Product name iPR1135 iPR1125 iPR1110 iPR1135 iPR1125 iPR1110 iPR1135 iPR1125 iPR1110 iPR1135 iPR1125 iPR1110 The timing of occurrence Assumed cause Work procedure

A3 thick paper A3 plain paper LDR thick paper LDR plain paper

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

Approx.

12.3mm

When the disengagement

of the Registration Roller

during secondary transfer

of the image

Failure in the Active Registration Uni

Refer to Work procedure 1-1Where on the paper does

the image failure occur?

(Distance from the leading

edge of the paper?)

Positionofthe

Approx.

54.6 mm

Approx.

9.4 mm

- Approx.

119.3 mm

Approx.

96.7 mm

Approx.

55.5 mm

Approx.

42.8 mm

- - Approx.

107.5 mm

Approx.

84.9 mm

Approx.

43.7 mm

When the leading edge of

the paper enters the

Secondary Transfer Unit

during exposure of the

drum

- Misalignment of the fixing position

or a loose Fixation Screw of the ITB

Unit, Process Unit or the Laser

Scanner Unit

-Pressurization error of the

Secondary Transfer Roller

Refer to Work procedure 1-2

Positionofthe

poorimage

Approx.

66.9 mm

Approx.

21.7 mm

- Approx.

131.6 mm

Approx.

109.0 mm

Approx.

67.8 mm

Approx.

55.1 mm

Approx.

9.9 mm

- Approx.

119.8 mm

Approx.

97.2 mm

Approx.

56.0 mm

When the disengagement

of the Registration Roller

during exposure of the

drum

Failure in the Active Registration Uni

Refer to Work procedure 1-3

Approx.

Approx.

- Approx.

Approx.

Approx.

Approx.

Approx.

- Approx.

Approx.

Approx.

When the leading edge of

the paper enters the Fixing

Misalignment of the fixing position or

a loose Fixation Screw of the Frame

Refer to Work procedure 1-4

Positionofthe

poorimage

.

.

.

.

.

.

.

.

.

.

Roller during primary

transfer of the image

Body, Process Unit or ITB, or

abnormality in the spring of the

Primary Transfer Assembly

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

Approx.

227.2 mm

When the leading edge of

the paper enters the Fixing

Roller during secondary

Hard heavy paper is used. Refer to Work procedure 1-5

rans

er o

e

mage

Approx.

281.8 mm

Approx.

236.6 mm

Approx.

152.8 mm

Approx.

346.5 mm

Approx.

323.9 mm

Approx.

282.7 mm

Approx.

270.0 mm

Approx.

224.8 mm

Approx.

141.0 mm

Approx.

334.7 mm

Approx.

312.1 mm

Approx.

270.9 mm

When the leading edge of

the paper enters the Fixing

Roller during exposure of

the drum

Misalignment of the fixing position or

a loose Fixation Screw of the Frame

Unit, Process Unit or the Laser

Scanner Unit

Refer to Work procedure 1-6

pprox.

313.6 mm

pprox.

268.4 mm

pprox.

184.6 mm

pprox.

378.3 mm

pprox.

355.7 mm

pprox.

314.5 mm

pprox.

301.8 mm

pprox.

256.6 mm

pprox.

172.8 mm

pprox.

366.5 mm

pprox.

343.9 mm

pprox.

302.7 mm

en t

e tra

ng e

ge o

the paper passes through

the Secondary Transfer

Roller during primary

transfer of the image

stort

on o

t

e

e

t or a

oose

Fixation Screw of the ITB Unit Refer to Work procedure 1-7