*1: Install the Service Tool version 1.030 or later to a pre-registered computer.

*2: Only for CD / DVD printing supported regions.

(2) Periodic maintenance

No periodic maintenance is necessary.

(3) Periodic replacement parts

There are no parts in this printer that require periodic replacement by a service engineer.

(4) Replacement consumables

There are no consumables that require replacement by a service engineer.

HP300

Ink system

function check - At logic board replacement

- At spur unit replacement

- At carriage unit replacement

To maintain detection

functionality for presence

of the ink tanks and each

ink tank position.

Service Tool*1

Perform in the

service mode.

1 min.

CD / DVD

detection sensor

light volume

correction*2

- At logic board replacement

- At carriage unit replacement To correct the light

volume for the CD / DVD

detection sensor.

Service Tool*1

Perform in the

service mode.

2 min.

LF / Eject

correction - At logic board replacement

- At paper feed roller replacement

- At platen unit replacement

To correct the paper

feeding amount according

to each LF and eject

roller.

Service Tool*1

Perform in the

service mode.

5 min.

Carriage shaft

position

adjustment

- At carriage unit replacement

- At carriage unit removal To set the carriage shaft

to the original position

prior to removal or

replacement of the

carriage unit, put a mark

on the main chassis

before removal of the

carriage unit.

None. 1 min.

Eject roller

position

adjustment

- At platen unit replacement

- At platen unit removal To prevent the eject roller

from being deflected due

to the pressure of the spur

unit.

None. 1 min.

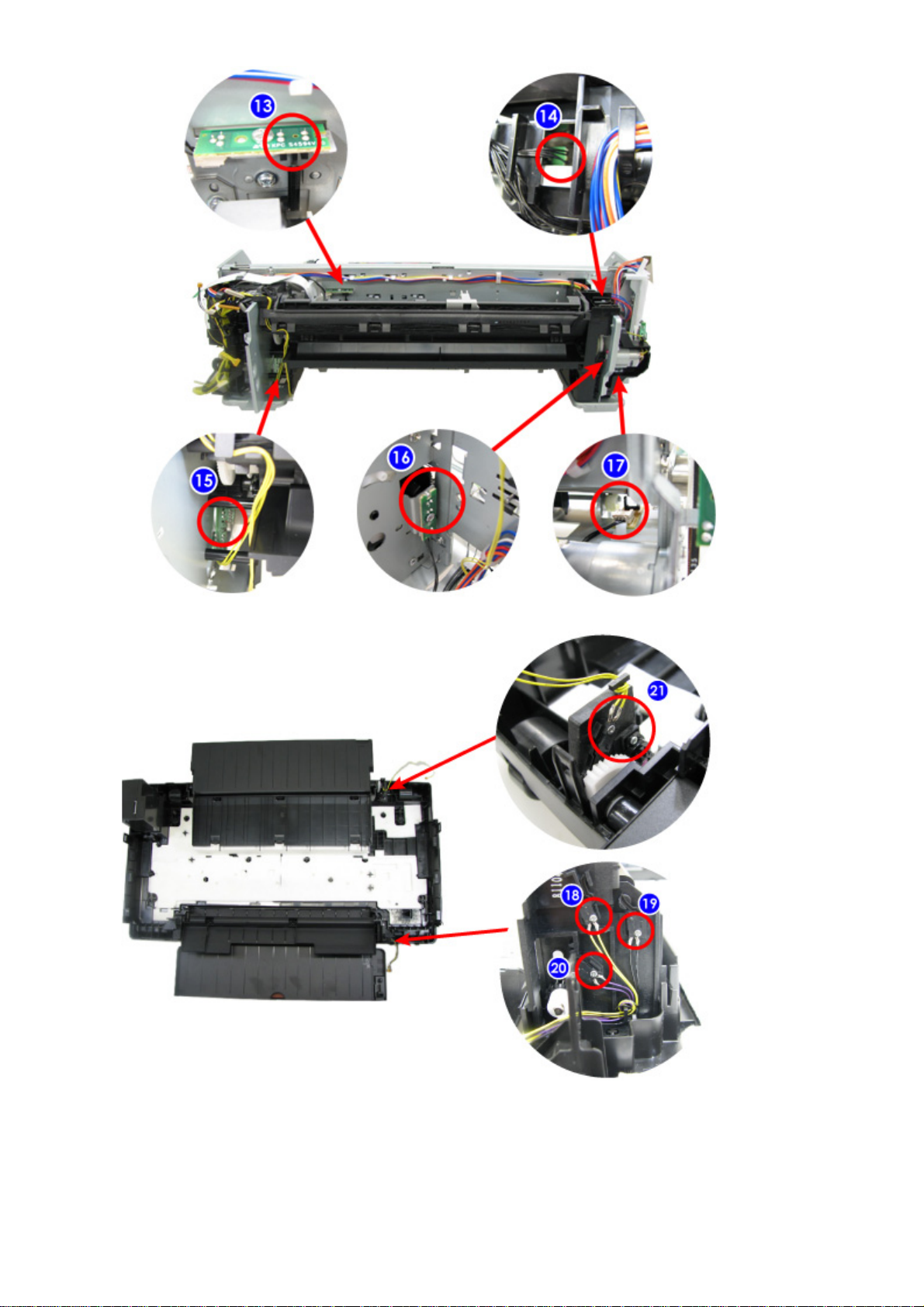

- Red screws as well as regular (silver) screws need adjustments during servicing.

- The screws securing the paper feed motor may be loosened only at replacement of the

paper feed motor unit. DO NOT loosen them in other cases.

- The screws securing the carriage shaft may be loosened only at removal of the carriage

unit. DO NOT loosen them in other cases.

- The screws securing the eject roller may be loosened only at removal of the platen

unit. DO NOT loosen them in other cases.