6

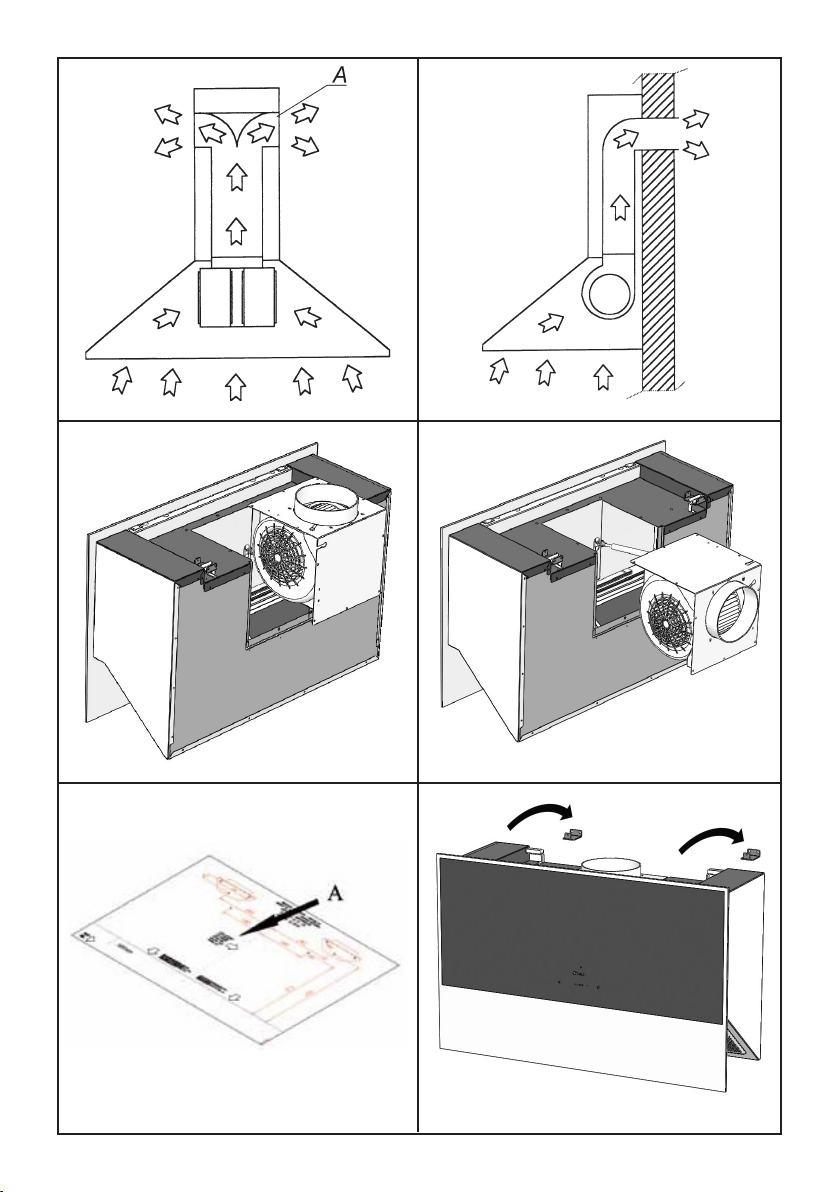

INSTALLATION

Before installing the appliance, make sure

that none of the parts are damaged in any way.

In case of damaged parts, contact your retailer

and do not proceed with installation.

Read all of the following instructions with care

before installing the appliance.

- Use an air outlet pipe of the shortest possible

length.

- Limit the number of pipe bends.

- Use a material approved by standards and re-

gulations.

- Avoid any sudden changes in ducting

dimensionsn (we recommended a constant

diameter of 150 mm or equal surface area).

- The manufacturer shall not respond for air

capacity or noise problems due to non

compliance with above mentioned instructions,

and no warranty shall be given for such

installations.

The TAU760 extractors have been designed to

have the possibility of directing the air outlet to

the rear of the appliance, instead of out of the

top; if you choose to use this function, it is

necessary to remove the x10 screws from the

motor unit (Fig. 3), remove the motor unit and

rotate it in such a way to direct the air outlet

spigot towards the rear side of the appliance

(Fig. 4); then place the motor unit back into

position and tighten the screws previously

removed.

By using the drilling template (Fig .5A), drill the

holes for the wall bracket installation;

Appliances shall be installed at a minimum

distance of 500mm from the cooking surface.

Drill the remaining holes indicated by the hole

drilling template.

Fix the brackets to the wall, by using the wall

plugs and screws supplied with the product;

Hang the body (Fig. 6) to the wall brackets

previously fixed.

Tighten the two screws into the wall bracket

(Fig. 7A), as they are necessary for the

appliance to secure to the wall. Then check

that the hood is perfectly flush with the wall,

otherwise adjust the screws shown in Fig.7B.

Tighten the screw if you need to lift up the

corresponding side, or unscrew it, in case you

need to reduce the height.

TAU760

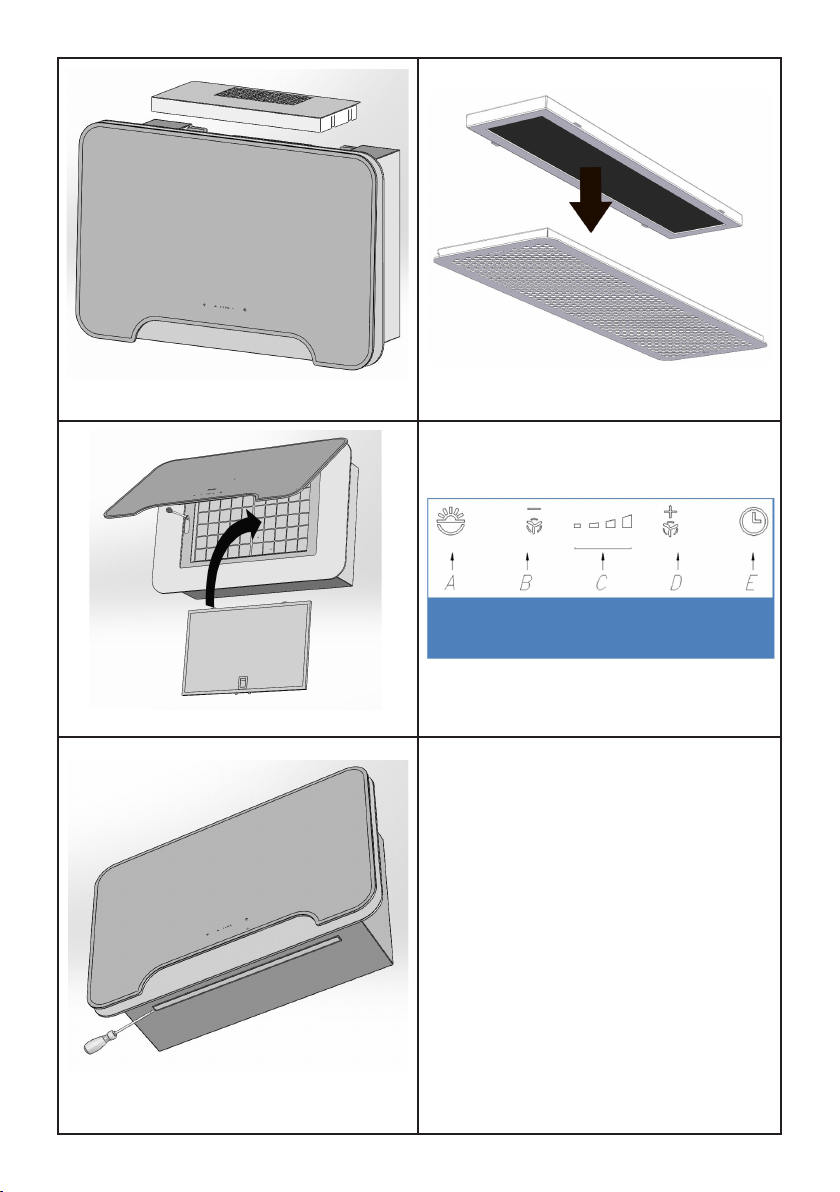

Remove the metal grease filters, which are

magnetically secured to the appliance, by using

either a hand tool or a knife edge. Act on the

slot found in the filter sides, as shown in Fig. 8.

Fix the appliance to the wall with the screws

provided, as per Fig. 11.

NOV800

Open the front panel by pulling the lower side

upwards, as shown in Fig. 7, then remove the

grease filter. Fix the appliance to the wall with

the screws provided, as per Fig. 11.

Vented mode

Using the supplied wall plugs and screws, fix the

chimney support bracket (Fig. 12) to the wall

and/or the ceiling. The bracket must be fixed in a

central position in respect of the air outlet flange.

Connect the motor air outlet flange to the ducting

by using a suitable pipe. Perform the electric

connection. Place the two ornamental pipes on

the hood body; lift the internal pipe up until it

reaches the ceiling;

then x it to the pipe bearing bracket, by using the

two self-threaded screws provided.

Recirculation mode

Install the air outlet grill above the hood in the

relative seat (refer to Fig. 13). The stainless steel

chimneys are not necessary.

TAU760

The charcoal filters are installed directly onto the

rear side of the grease filters (see Fig. 14).

NOV800

The charcoal filters are installed as shown in

Fig. 15, by fitting it into its seat which is found

just behind the metal grease filter.

Charcoal filters should be replaced accordingly

to the effective use of the hood, and in any case

at least once every 6 months.

To purchase replacement charcoal filters, please

visit www.caple.co.uk or call our sales office on

0117 938 1900.

Note: Charcoal filters do not come included, and

must be ordered separately if required.