ance’s control panel (Fig. 2.1).

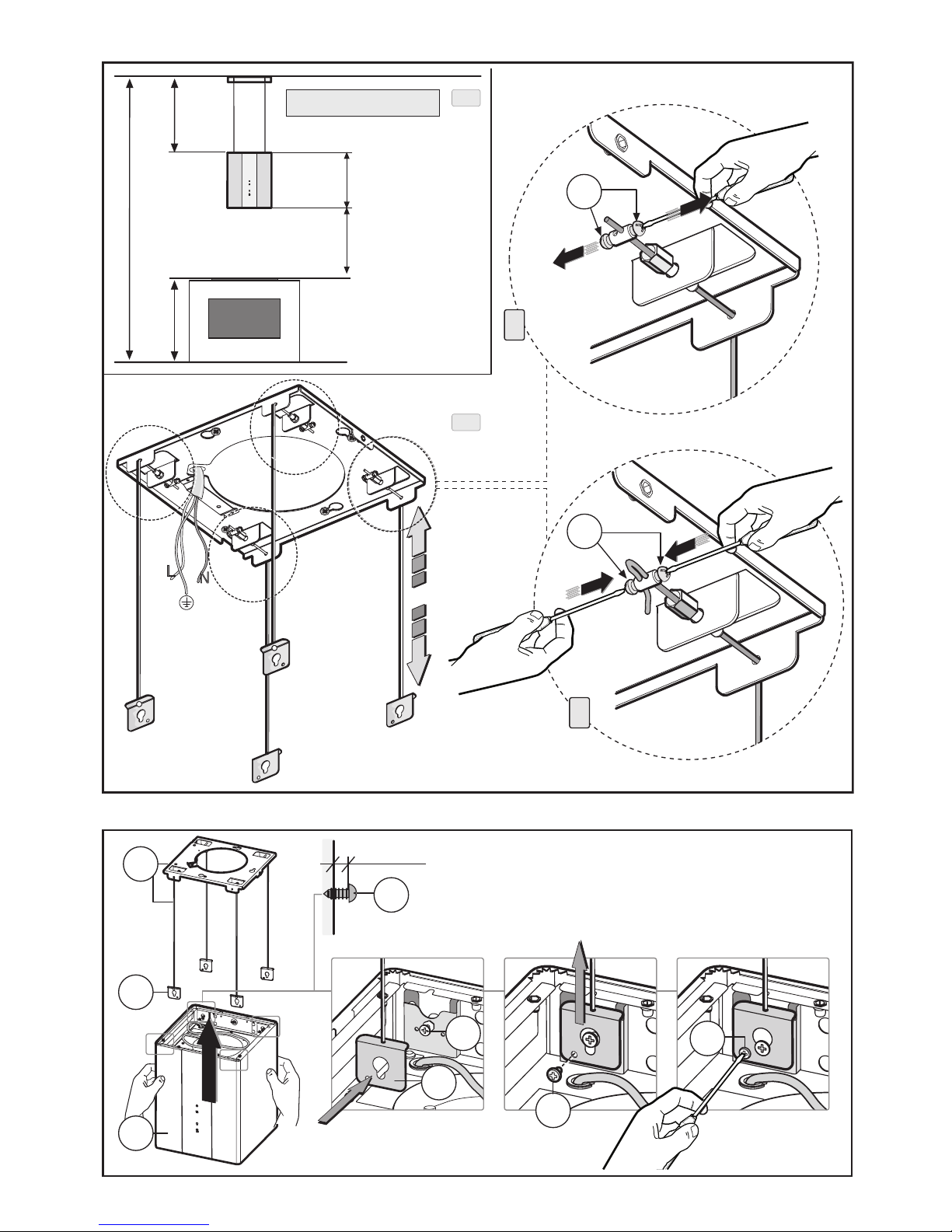

Drill 5 Ø8 holes in the ceiling and tighten 3 screws E without

tightening them completely making sure that the screws are

not inserted in the holes marked with an X on the drill hole

template (the screws and anchors must be suitable for the

type of wall).

- Take structure B (Fig. 2.2) and insert it on the 3 screws that

have not been tightened completely, in correspondence of

the 3 slots.

Make a small rotation to lock it in (Fig. 2.2).

- Tighten the fourth and the fth screw X and the 3 remain-

ing one to lock structure B into its nal position.

To adjust cable height it is necessary to refer to the lengths

shown in (Fig. 3.1)

- To adjust the cable, rst loosen the 2 screws Aof the del

clamp as shown in gure 3.2 (X).

- Once the length of the cable has been adjusted, tighten

the 2 screws Aas shown in gure 3.2 (Y).

- Couple the hood body Cand the structure Bin correspond-

ence of the 4 slots Fand the four screws G (not completely

tightened) gure 4 - phase 1.

- Rest the hood body on the 4 slots gure 4 - phase 2

- Tighten the 4 screws Gand fasten the structure perma-

nently Bto the hood Cwith the 4 safety screws Hgure 4

- phase 3.

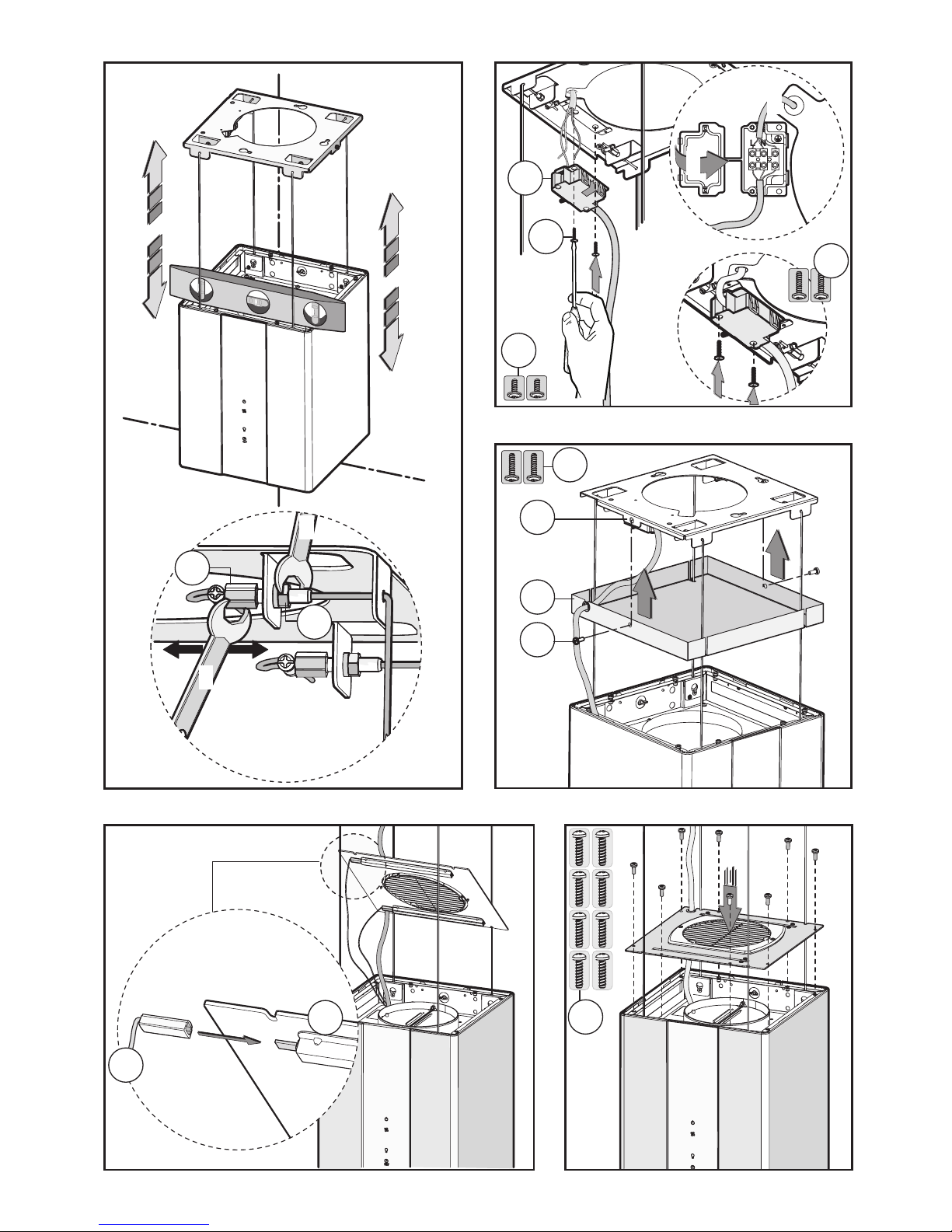

- Using a level align the hood by turning the adjustment

screws Ras shown in gure 5.

- Once the hood is aligned, in order to lock the adjustment

screws permanently R, tighten the nut Das shown in g. 5.

- Before completing the electrical connection, fasten the

box Sto the bracket using the 2 screws Dgure 6 - phase 1.

- Open the box lid Sremoving the adhesive tape.

- Connect to the electrical network as shown in gure 6 -

phase 2.

- Close the lid of the box Sgure 6 - phase 3, and fasten with

the two screws Egure 6 - phase 4

- Take the aesthetic frame Cand using the 2 screws Afasten

it to the structure B g. 7.

Attention! Based on the model that has been purchased,

the product may be equipped with COURTESY LIGHTS OP-

TIONAL, before fastening the small cupola to the hood body

connect the lights as shown in gure 8.

- Pass the power supply cable through the slots of the small

cupola as shown in gure 9.

- Take the small cupola and fasten it to the hood using the 8

screws Gas shown in gure 9.

- If your model is like the one shown in gure 10 it is nec-

essary to fasten the decorative cover M1 - M2.

- In correspondence with the hood body there are 4

(right)+ 4 (left) screws Xthat are not completely tight-

ened gure 10 - phase 1, take the decorative cover M2

and slide it down until it clamps onto the slot phase 2-3-

4-5.

- Take a spanner that is suitable for the screws Xand

tighten them to fasten the decorative cover perma-

nently M2.

- Repeat the same operation for the M1 cover.

• Filtering version

- Before proceeding with the replacement of the regen-

erative lter, open the aesthetic panel.

- Remove the aluminium panel by pulling the handle as

shown in g. 11.

- Remove the brackets from their housing and pull them

outwards. (Fig. 12).

Unlike traditional carbon filters, this carbon filter can be

washed and reactivated for approximately 12-15 times.

With normal hood use, this lter should be cleaned once

every 2-3 months. The lter can be washed in a dishwasher

at the highest temperature using a standard dishwasher

detergent.

After washing, dry the lter in the oven at 100° C for 10-15

minutes to reactivate it.

The lter will retain its odour-absorbing capacity for three

years, after which it will have to be replaced.

USE AND MAINTENANCE

•We recommend that the cooker hood is switched on before

any food is cooked.

We also recommend that the appliance is left running for

15 minutes after the food is cooked, in order to thoroughly

eliminate all contaminated air.

The eective performance of the cooker hood depends on

constant maintenance; the anti-grease lter and the active

carbon lter both require special attention.

• The anti-grease lter is used to trap any grease particles

suspended in the air, therefore is subject to saturation (the

time it takes for the lter to become saturated depends on

the way in which the appliance is used).

-Topreventpotentialrehazards,theanti-greaseltersshould

be washed a minimum of every 2 months (it is possible to use

the dishwasher for this task).

- After a few washes, the colour of the lters may change.This

does not mean they have to be replaced.

If the replacement and washing instructions are not followed,

the anti-grease lters may present a re hazard.

• The active carbon lters are used to purify the air which is

released back into the room.

The active carbon lter saturation level depends on the fre-

quency with which the appliance is used, the type of cooking

performed and the regularity with which the anti-grease

lters are cleaned.

• Clean the cooker hood frequently, both inside and outside,

using a cloth which has been dampened with denatured

alcohol or neutral, non-abrasive liquid detergents.

ATTENTION!

Before proceeding with the replacement of halogen lights it

is necessary to open the aesthetic panel gure 13 - phase 1;

loosen the two screws F lift the small panel Gas shown in g-

ure 13 - phase 2-3.

• Replacing halogen light bulbs (Fig. 13 - phaset 4).

To replace the halogen light bulbs B, remove the glass pane

C using a lever action on the relevant cracks.

Replace the bulbs with new ones of the same type.

Caution: do not touch the light bulb with bare hands.

Optional !

As an optional the product may be equipped with side halo-

gen lamps gure 14.

To replace them, it is necessary to remove the decorative

cover M1 or M2 and repeat the same operations shown in

g. 13 - phase 4“Replacing halogen lamps”.

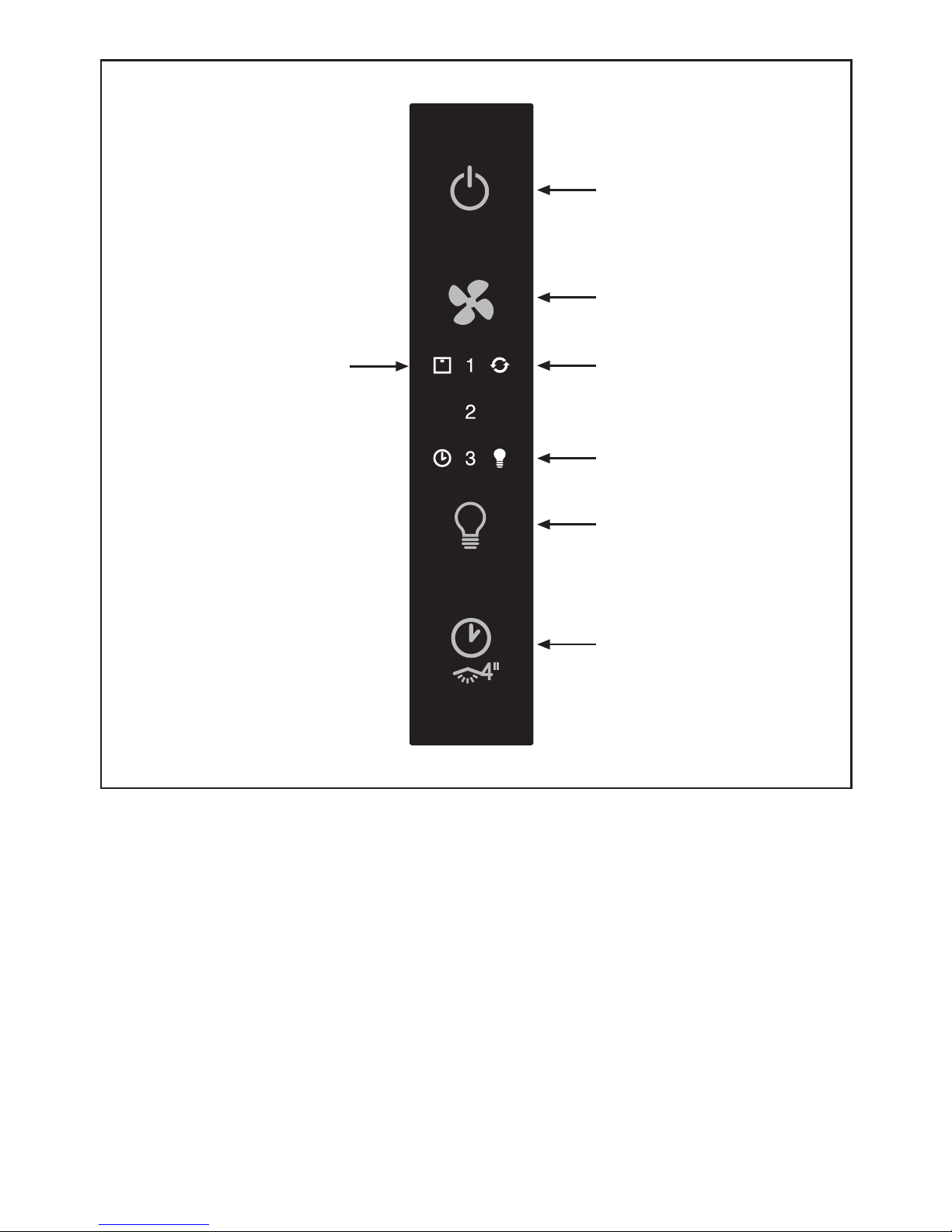

• Commands: (Fig.15)

NOTE: With this control it is possible to manage the appliance

also with a remote control to be requested as accessory.

Power Button (A) = the on / o button switches on and o

the whole hood (motor and lights).

By pressing the button the motor starts at 1st speed.

Fan Speed button (B) = From the OFF position, press once

for the 1st speed, twice for the 2nd speed and three times

- 10 -