Welcome and Congratulations

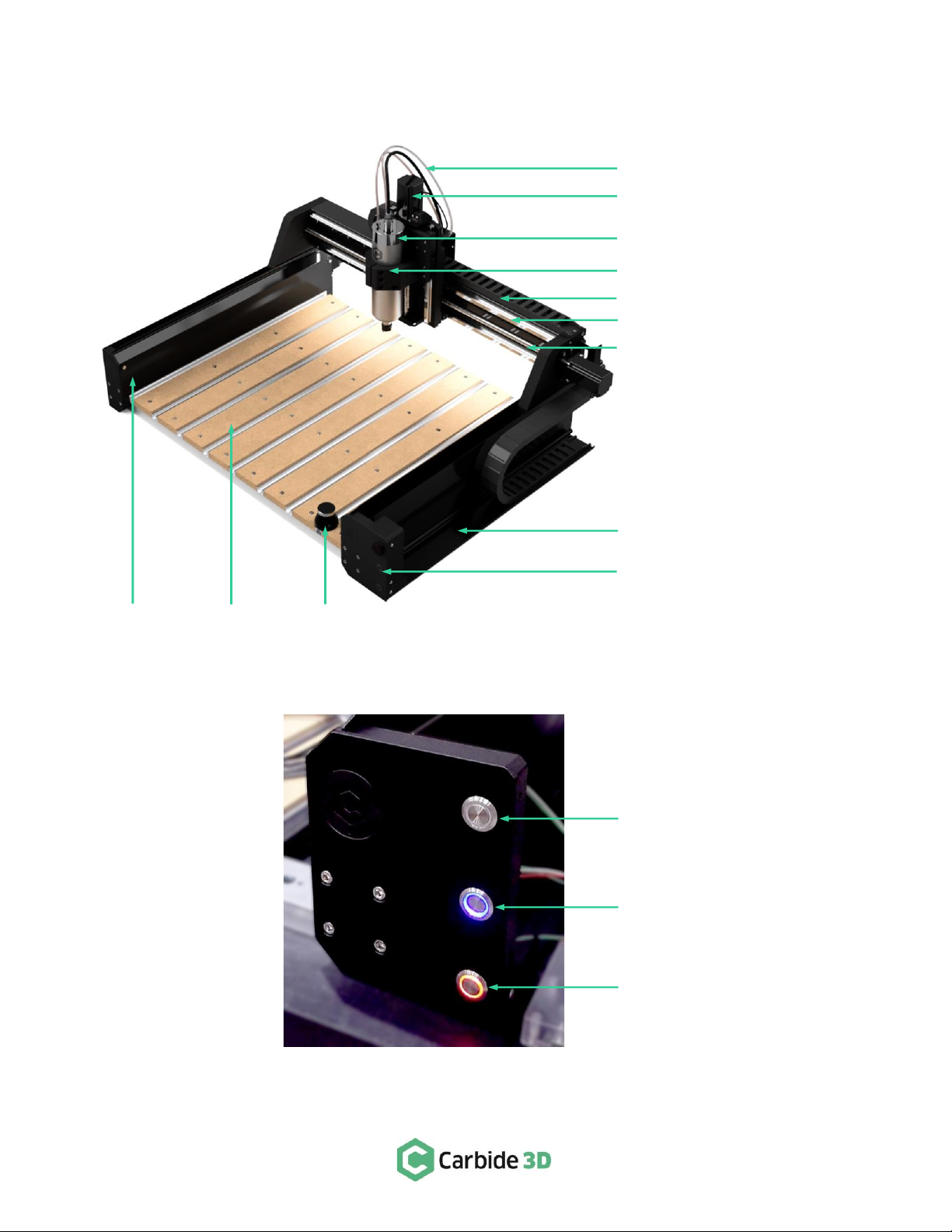

The Shapeoko HDM is a high-end, professional-graded CNC, the result of two years of prototyping and testing.

It cuts wood and non-ferrous metals (aluminum and brass) with ease and accuracy and will run all day long

without breaking a sweat. The machine comes fully-assembled, with the wiring already installed in the drag

chains and plugged into the Warthog controller. The Shapeoko HDM features:

•80mm water-cooled spindle (110 V or 220 V) with VFD control and chiller.

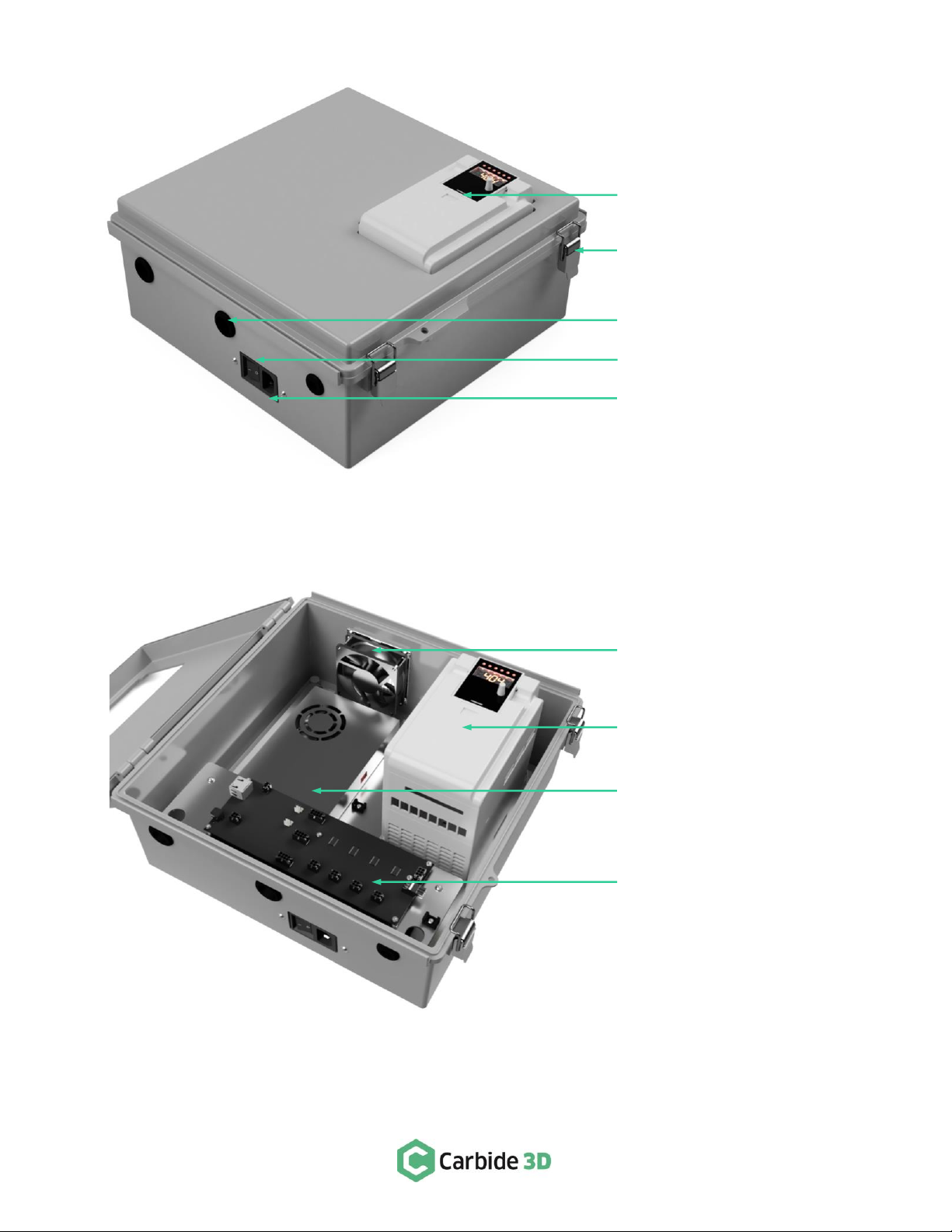

•Carbide 3D Warthog electronics.

•Hybrid Table with T-slot workholding.

•HG-15 linear bearings on every axis.

•Heavy-duty custom extrusions.

•16mm ballscrews on every axis with custom ballscrew wipers on X and Y-axis.

•Optical isolation and RS-422 serial connection for reduced electrical noise and static discharge.

In this guide we’ll walk you through everything you need to know to get started using your Shapeoko HDM. If you

encounter any issues setting up your machine, contact our tech support team at support@carbide3d.com and

we’ll get you up and running.

Do Not Connect to Ethernet-Enabled Devices

While an RS-422 Ethernet cable is used to connect the electronics cabinet to the computer adapter, the

Shapeoko HDM is NOT an Ethernet device. Do not use the RS-422 Ethernet cable to connect the electronics

cabinet or computer adapter to any Ethernet-enabled device, such as a modem or internet router.

Software Requirements

Carbide Motion version 5 or higher required for the Warthog controller.

Warranty

The Shapeoko HDM is covered by our standard Shapeoko warranty. Visit carbide3d.com/policy/warranty for

details.

Important Call-Outs

Throughout the guide, you will find information that we’ve called out for you to pay particular attention to. We

use three types of call-outs: Warnings, Notes, and Pro Tips.

Join the Carbide 3D Community

Join the Carbide 3D Community. Find or start a discussion on topics such as machine troubleshooting, product

announcements, software issues (Carbide Create, Carbide Motion, MeshCAM, Carbide Copper, Fusion 360),

problems with tutorials, community contests, project galleries, and more.