4

Rotor Cleaning Device ·KLINGENBURG

Table of Contents

1. Unpacking and checking scope of delivery ..................................................................... 6

2. Before you begin – safety ................................................................................................ 10

2.1. Symbols in this manual..................................................................................... 10

2.2. Intended use ..................................................................................................... 11

2.3. Personnel qualification ..................................................................................... 12

2.4. Personal protective equipment ......................................................................... 14

2.5. Working and danger areas ............................................................................... 15

2.6. Residual risks ................................................................................................... 15

2.6.1. Electrical hazards........................................................................... 15

2.6.2. Hazards from moving parts ............................................................ 16

2.6.3. Tripping and slipping hazards ........................................................ 16

2.6.4. Hazards from pressurised media ................................................... 16

2.6.5. Noise hazards ................................................................................ 17

2.7. Operator’s obligations....................................................................................... 18

2.8. Safety devices .................................................................................................. 19

2.9. Securing against being switched on again ....................................................... 19

3. Packing .............................................................................................................................. 20

4. Technical specifications................................................................................................... 21

4.1. Cleaning rail...................................................................................................... 21

4.2. Control units...................................................................................................... 22

4.3. Stepper motor................................................................................................... 25

4.4. Media supply..................................................................................................... 26

4.4.1. Compressed Air ............................................................................. 26

4.4.2. High pressure water ....................................................................... 26

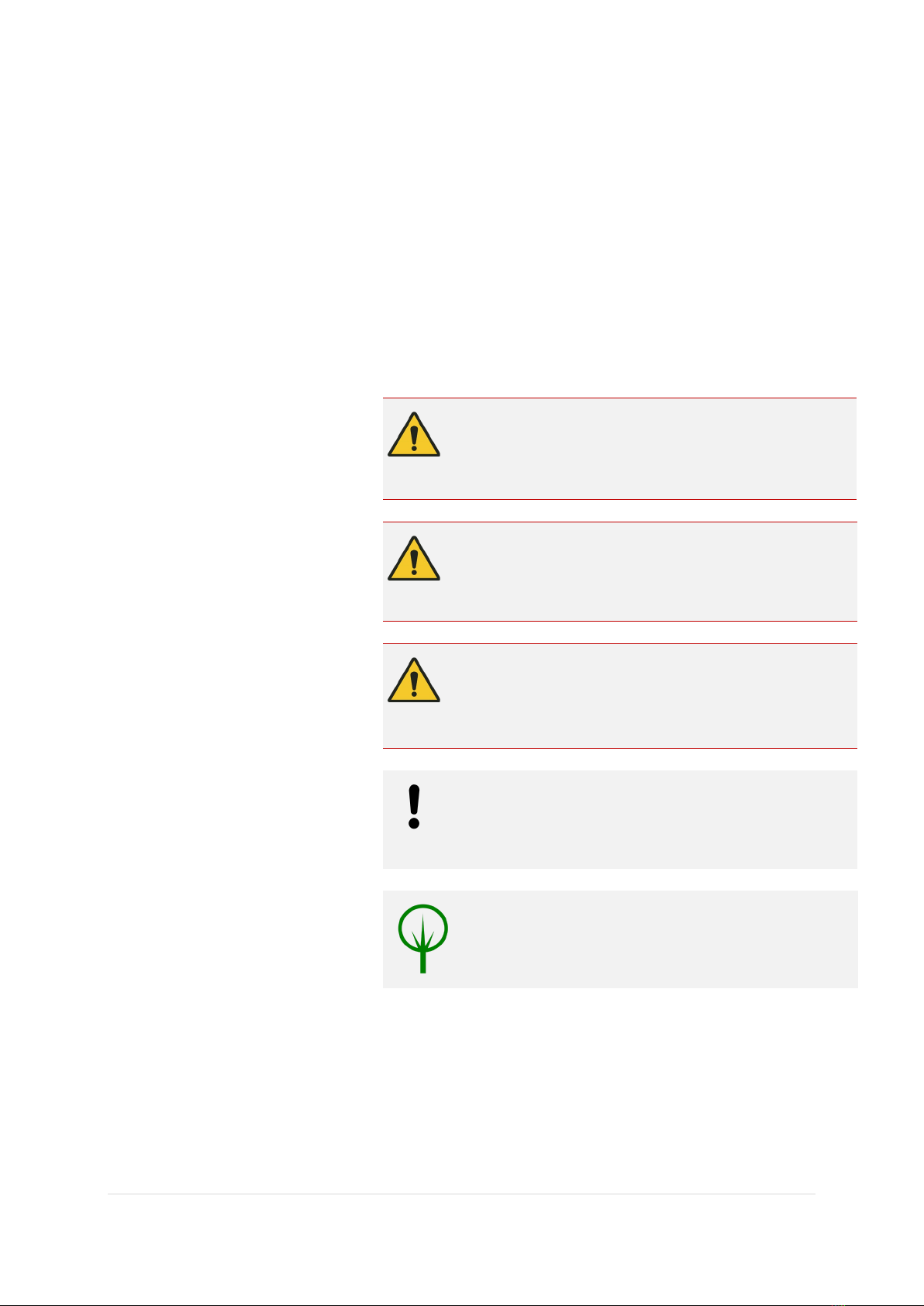

4.5. Compressed air solenoid valve ........................................................................ 27

4.6. Sensors............................................................................................................. 29

5. Layout and function.......................................................................................................... 31

5.1. Function layout ................................................................................................. 31

5.2. Functional description....................................................................................... 32

5.3. Operating and display elements ....................................................................... 33

5.4. Sensors............................................................................................................. 34

5.5. Connections...................................................................................................... 34

6. Installation ......................................................................................................................... 38

6.1. Safety instructions for the installation ............................................................... 38

6.2. Mechanical installation ..................................................................................... 39

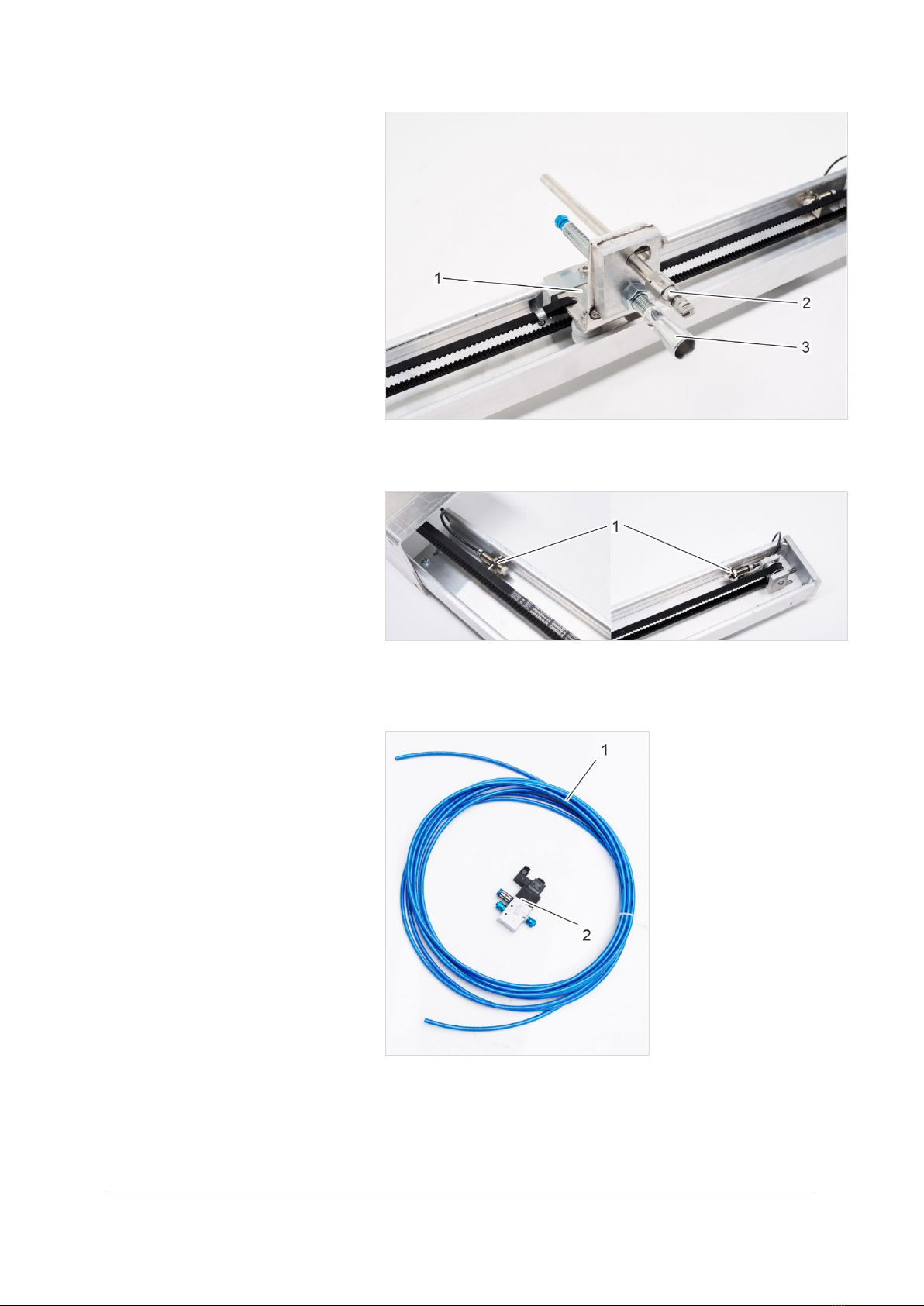

6.2.1. Cleaning rail ................................................................................... 39

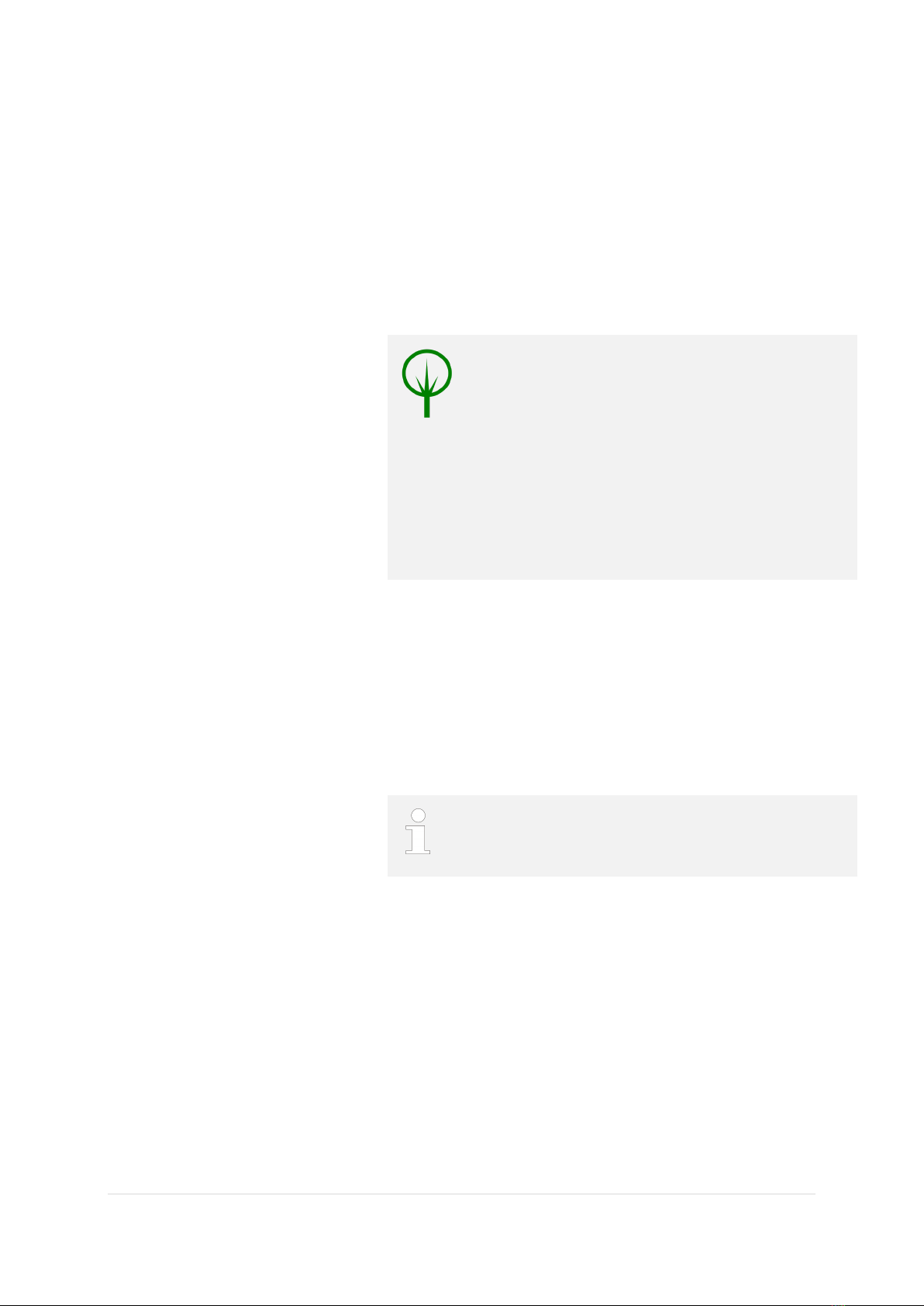

6.2.2. Drip pan.......................................................................................... 51

6.2.3. Cleaning rail cover ......................................................................... 53