Emheater EM15 Series User manual

EM15 Series Frequency Inverter

EM15 User’s Manual Preface

I

Preface

Thank you for purchasing the EM15 series frequency inverter developed by China EM Technology Limited.

EM15 series inverter is our company adopted the new concept to research and developed high-performance

product. With unique control model, this inverter can realize high torque, high precision, wide variable speed and

low noise drive; And PID regulation, simple PLC, flexible input and output terminals, Auto voltage regulation,

rapid Current Limit, Torque limited and control, field bus control and a series of practical operation, control function,

which provide a highly integrated solution for equipment manufacturers and customers, in speed, energy saving,

automatic control and other aspects, to meet the application demands for different customers.

Before unpacking, please check carefully:

⚫Whether the nameplate model of frequency inverter are consistent with your order ratings. The box contains

the frequency inverter, user manual.

⚫Whether the frequency inverter is damaged during transportation. If you find any omission or damage, please

contact us or your local supplier immediately.

First-time Use

For the users who use this product for the first time, read the manual carefully. If in doubt concerning some

functions or performances, contact the technical support personnel to ensure correct use.

Due to the continuous improvement of frequency inverter, this document will be updated without prior notice.

EM15 series frequency inverter complies with the following international standards. All products have acquired

the CE certification.

IEC/EN61800-5-1: 2003 Variable speed electric drive system safety requirements;

IEC/EN61800-3: 2004 Variable speed electric drive system, Part 3: The Electro Magnetic Compatibility (EMC)

Standards of Product and its specific testing methods.

Note:

⚫There are all parameters list integrated at appendix II.

Version:V1.0.12

Table of Contents EM15 User’s Manual

II

Table of Contents

1. Safety Information and Precautions.............................................................................................................1

1.1 Safety Information.................................................................................................................................1

1.2 General Precautions...............................................................................................................................3

2. Product Information.....................................................................................................................................5

2.1 Products Lable and Model Designation.................................................................................................5

2.1.1 Product appearance.............................................................................................................................5

2.2 Technical Specifications........................................................................................................................6

2.3 Model and Technical data......................................................................................................................7

2.4 Product appearance and installation dimension.....................................................................................9

2.5 Daily maintenance of frequency inverters...........................................................................................12

2.6 Selection Guide of braking component ...............................................................................................13

3. Installation of Frequency Inverter..............................................................................................................16

3.1 Installation environment......................................................................................................................16

3.2 Installation direction and space............................................................................................................16

3.3 Peripheral Devices Connection Diagram.............................................................................................17

3.4 Instructions of Main Circuit Peripheral Devices .................................................................................17

3.5 Model Selection of Main Circuit Peripheral Devices..........................................................................18

3.6 Removal and mounting of operating panel and cover.........................................................................19

3.7 Connection Terminals Diagram Description........................................................................................21

3.8 Sketch and Description of Main Circuit Terminals .............................................................................21

3.9 Cautions for Main Circuit Wiring........................................................................................................23

3.10 Control Circuit and Main Circuit Terminals Description ..................................................................25

4. Operation and display................................................................................................................................29

4.1 Instruction of operation and display ....................................................................................................29

4.2 Viewing and Modifying Function Codes.............................................................................................30

4.3 Monitoring Status Parameters..............................................................................................................30

4.4 Password Setting..................................................................................................................................31

4.5 Motor parameter auto-tuning...............................................................................................................31

5. Description of Function Codes..................................................................................................................32

5.1 Group b0: Basic Function Parameters.................................................................................................32

5.2 Group b1: Start/Stop Control Parameters............................................................................................40

5.3 Group b2: Auxiliary Functions............................................................................................................42

5.4 Group b3: Input Terminals...................................................................................................................47

5.5 Group b4: Output Terminals................................................................................................................53

5.6 Group b5: Pulse/Analog input terminals .............................................................................................59

5.7 Group b6: Pulse/analog output terminals.............................................................................................62

5.8 Group b7: Virtual digital input (VDI)/digital output (VDO) terminals ...............................................63

5.9 Group b9: Keypad and Display ...........................................................................................................66

5.10 Group bA: Communication parameters.............................................................................................69

5.11 Group bb: Fault and Protection..........................................................................................................70

5.12 Group bC: Fault detection Parameters...............................................................................................76

5.13 Group bd Motor protection................................................................................................................77

5.14 Group C0: Process Control PID Function .........................................................................................77

5.15 Group C1:Multi-function...................................................................................................................82

5.16 Group C2: Simple PLC......................................................................................................................84

EM15 User’s Manual Table of Contents

III

5.17 Group C3: Constant pressure water supply parameters.........................................................................88

5.18 Group d0: Motor Parameters.............................................................................................................88

5.19 Group d1: Motor vector control parameters......................................................................................91

5.20 Group d2: Motor V/F Control Parameters.........................................................................................94

5.21 Group d6: Control Optimization Parameters 1..................................................................................99

5.22 Group U0: Monitoring Parameters..................................................................................................100

5.23 Group A0: System parameters.........................................................................................................105

5.24 Group A2: Control Optimization Parameters 2 ...............................................................................106

6. EMC (Electromagnetic compatibility).....................................................................................................108

6.1 Definition...........................................................................................................................................108

6.2 EMC Standard Description................................................................................................................108

6.3 EMC Guide........................................................................................................................................108

7. Fault Diagnosis and Solution...................................................................................................................111

7.1 Fault Alarm and Countermeasures.....................................................................................................111

7.2 Common Faults and Solutions...........................................................................................................114

Appendix I.Modbus communication protocol.............................................................................................117

I. About Protocol......................................................................................................................................117

II. Application Methods...........................................................................................................................117

III. Bus structure......................................................................................................................................117

Appendix II. Function Code Table...............................................................................................................126

Appendix III ................................................................................................................................................156

EM15 User’s Manual 1. Safety Information and Precautions

1

1. Safety Information and Precautions

In this manual, the notices are graded based on the degree of danger:

Danger

Indicates that failure to comply with the notice will result in severe personal injury or

even death.

Warning

Indicates that failure to comply with the notice will result in personal injury or

property damage.

Read this manual carefully so that you have a thorough understanding. Installation, commissioning or

maintenance may be performed in conjunction with this chapter. EMHEATER will assume no liability or

responsibility for any injury or loss caused by improper operation.

1.1 Safety Information

Before

installation

Danger

⚫Do not use damaged or missing components frequency inverter. Failure to

comply will result in personal injury.

⚫Please use the electric motor with upper B insulation class. Failure to comply

will result in personal injury.

During

installation

Danger

⚫Install the frequency inverter on incombustible objects such as metal, and keep it

away from combustible materials. Failure to comply may result in a fire.

Warning

⚫When two frequency inverters are laid in the same cabinet, arrange the

installation positions properly to ensure the enough cooling effect.

⚫Do not drop wire residue or screw into the frequency inverter. Failure to comply

will result in damage to the frequency inverter.

Wiring

Danger

⚫Wiring must be performed only by qualified personnel under instructions

described in this manual. Failure to comply may result in unexpected accidents.

⚫A circuit breaker must be used to isolate the power supply and the frequency

inverter. Failure to comply may result in a fire.

⚫Ensure that the power supply is cut off before wiring. Failure to comply may

result in electric shock.

⚫Connect the frequency inverter to ground properly by standard. Failure to

comply may result in electric shock.

Warning

⚫Never connect the power supply cables to the output terminals (U, V, W) of the

Frequency inverter. Failure to comply will result in damage to the frequency

inverter.

⚫Make sure that all the connecting wires comply with the requirement of EMC

and the safety standard in the region. Use wire sizes recommended in the

manual. Failure to comply may result in accidents.

⚫Never connect the braking resistor between the DC bus terminals (P+) and (P-).

Failure to comply may result in a fire.

1. Safety Information and Precautions EM15 User’s Manual

2

Before

power-on

Danger

⚫Check that the following requirements comply with:

The voltage class of the power supply is consistent with the rated voltage class of

the frequency inverter. The input terminals (R, S, T) and output terminals (U, V,

W) are properly connected. No short-circuit exists in the peripheral circuit. The

wiring is fastened. Failure to comply will result in damage to frequency inverter.

⚫Cover the frequency inverter properly before power-on to prevent electric shock.

Before

power-on

Warning

⚫Do not perform the voltage resistance test on any part of the frequency inverter

because such test has been done in the factory. Failure to comply will result in

accidents.

⚫All peripheral devices must be connected properly under the instructions

described in this manual. Failure to comply will result in accidents.

After

power-on

Danger

⚫Do not open the frequency inverter’s cover after power-on to prevent from

electric shock.

⚫Do not touch the frequency inverter with wet hand and its peripheral circuit to

prevent from electric shock.

⚫Do not touch the terminals of the frequency inverter (including the control

terminals). Failure to comply may result in electric shock.

⚫Do not touch the U, V, W terminal or motor connecting terminals when

frequency inverter automatically does safety testing for the external high-voltage

electrical circuit. Failure to comply may result in electric shock.

Warning

⚫Note the danger during the rotary running of motor when check the parameters.

Failure to comply will result in accidents.

⚫Do not change the factory default settings of the frequency inverter. Failure to

comply will result in damage to the frequency inverter.

During

operation

Danger

⚫Do not go close to the equipment when selected the restart function. Failure to

comply may result in personal injury.

⚫Do not touch the fan or the discharging resistor to check the temperature. Failure

to comply will result in personal injury.

⚫Signal detection must be performed only by qualified personal during operation

Warning

⚫Avoid objects falling into the frequency inverter when it is running. Failure to

comply will result in damage to frequency inverter.

⚫Do not start/stop the frequency inverter by turning the contactor ON/OFF.

Failure to comply will result in damage to the frequency inverter.

Maintenance

Danger

⚫Do not repair or maintain the frequency inverter at power-on. Failure to comply

will result in electric shock.

⚫Repair or maintain the frequency inverter only after the charge light on

frequency inverter is powered off. This allows for the residual voltage in the

capacitor to discharge to a safe value. Failure to comply will result in personal

injury.

⚫Repair or maintenance of the frequency inverter may be performed only by

qualified personnel. Failure to comply will result in personal injury or damage to

the frequency inverter.

EM15 User’s Manual 1. Safety Information and Precautions

3

1.2 General Precautions

1.2.1 Motor insulation test

Perform the insulation test when the motor is used for the first time, or when it is reused after being stored for a

long time, or in a regular check-up, in order to prevent the poor insulation of motor windings from damaging the

frequency inverter. The motor must be disconnected from the frequency inverter during the insulation test. A

500-V mega-Ohm meter is recommended for the test. The insulation resistance must not be less than 5 MΩ.

1.2.2 Thermal protection of motor

If the rated capacity of the motor selected does not match that of the frequency inverter, especially when the

frequency inverter's rated power is greater than the motor's, adjust the motor protection parameters on the

operation panel of the frequency inverter or install a thermal relay in the motor circuit for protection.

1.2.3 Running at over 50 Hz

The frequency inverter provides frequency output from 0 to 3200 Hz with V/F mode (300 Hz is supported for

frequency inverter running at FVC and SVC mode). If the frequency inverter is required to run at over 50 Hz,

please consider the bearable capacity of the machine.

1.2.4 Vibration of mechanical device

The frequency inverter may encounter the mechanical resonance point at some output frequency points, which can

be avoided by setting the skip frequency.

1.2.5 Motor heat and noise

The output of the frequency inverter is pulse width modulation (PWM) wave with certain harmonic frequencies,

and therefore, the motor temperature, noise, and vibration are slightly greater than those motor runs at grid power

frequency (50 Hz).

1.2.6 Voltage-sensitive device or capacitor at output side of the Frequency inverter

Do not install the capacitor for improving power factor or lightning protection voltage-sensitive resistor at the

output side of the frequency inverter because the output of the frequency inverter is PWM wave. Otherwise, the

frequency inverter may suffer transient over current and even to be damaged.

1.2.7 Contactor at the Input or Output side of the frequency inverter

When contactor is installed between the input side of the frequency inverter for the power supplying, the

frequency inverter must not be started or stopped by the contactor switching on or off. If the frequency inverter

has to be operated by the contactor, ensure that the time interval between switching is at least one hour. Since

frequently charge and discharge will shorten the service life of the capacitor inside of the frequency inverter.

When a contactor is installed between the output side of the frequency inverter and the motor, do not turn off the

contactor when the frequency inverter is running. Otherwise, IGBT modules inside of frequency inverter may be

damaged.

1.2.8 When input voltage is over rated voltage range

The frequency inverter must not be used over the allowable voltage range specified in this manual. Otherwise, the

frequency inverter's components may be damaged. If required, please use a corresponding voltage transformer

device.

1.2.9 Prohibition of three-phase input changed into two-phase input

Do not change the three-phase power input of the frequency inverter to two-phase input. Otherwise, frequency

1. Safety Information and Precautions EM15 User’s Manual

4

inverter will be damaged.

1.2.10 Surge suppressor

The frequency inverter has a built-in voltage sensitive resistor for suppressing the surge voltage. Using frequently

surge place, please add extra surge voltage protection device at input side of frequency inverter.

Note: Do not add the surge suppressor at the output side of the frequency inverter.

1.2.11 Altitude and de-rating using

Where the altitude is above 1000 m and the cooling effect WEAKEN due to thin air, it is necessary to de-rate the

power of frequency inverter. Please contact our company for technical supporting.

1.2.12 Some special application

If wiring that is not described in this manual such as shared DC bus is applied, please contact the agent or our

company for technical supporting.

1.2.13 Scrap disposition

The electrolytic capacitors on the main circuit and PCB board may explode when they are burning. Poisonous gas

is generated when the plastic parts are burning. Please treat them as industrial waste by special way.

1.2.14 Matched Motor

The standard matched motor is suitable four-pole squirrel-cage asynchronous induction motor. For other types of

motor, please select a proper frequency inverter according to the rated motor current. If user uses inverter for

permanent magnet synchronous motor, please contact my company for selecting another series inverter..

The cooling fan is coaxial to rotor shaft of non-variable-frequency motor, which will reduce cooling effect when

the shaft rotational speed decreasing. If motor is required variable speed, add a separately cooling fan or replace

motor to variable-frequency motor.

The common standard parameters of the matched motor have been configured inside the frequency inverter. It is

still necessary to perform motor auto-tuning or modify the default values based on actual application. Otherwise,

the running result and protection performance will be weaken.

The frequency inverter may alarm and even be damaged when short-circuit exists on cables or inside the motor.

Therefore, perform insulation test when the motor and cables are newly installed or during routine maintenance.

During the test, make sure the frequency inverter is disconnected from the tested parts.

EM15 User’s Manual 2. Product Information

5

2. Product Information

2.1 Products Lable and Model Designation

EM15 Series Frequency Inverter

,

Products Type:

G: General use

P: Fan&Pump

,

Voltage range:

1: Single phase 220V

13: Single phase 220V to Three phase 380

2: Three phase 220V

3: Three phase 380V

4: Three phase 480V

5: Three phase 575V

6: Three phase 660V

,

Adaptable motor: 7d5: 7.5KW ;011: 11KW

Diagram 2-1 Products Label and Designation rules

2.1.1 Product appearance

Diagram 2-2 Nameplate

The housing types of the EM15 models are listed in the following table:

Plastic

Sheet metal

1PH 220V

0.75kW~2.2kW

--

3PH 220V

0.75kW~11kW

15kW~250kW

3PH 380V

0.75kW~22kW

30kW~500kW

3PH 480V

0.75kW~22kW

30kW~500kW

2. Product Information EM15 User’s Manual

6

2.2 Technical Specifications

Input

&Output

⚫Input Voltage: 220V/380V/480V/575V/660V±15%

⚫Input Frequency: 47~63Hz

⚫Input Frequency Resolution: 0.01Hz (Digital setting); maximum frequency×0.025% (Analog setting)

⚫Output Voltage:0~Rated input voltage

⚫Output Frequency: 0~320Hz(SFC); 0~3200Hz (V/F)

Technical Performance

⚫Control Mode:Sensor-less vector control(SVC); Closed-loop vector control (FVC); Voltage/Frequency

(V/F) control

⚫Carrier Frequency:0.5kHz~16kHz

⚫Startup Torque: G type: 0.5Hz/150% (FVC); 0Hz/180%(FVC); P type: 0.5Hz/100%

⚫Speed Range:1:100(SVC);1:1000(FVC)

⚫Speed Stability Accuracy:±0.5%(SVC);±0.02%(FVC)

⚫Torque Control Accuracy:±5%(FVC)

⚫Overload Capacity:G type:150% rated current 60s; 180% rated current 3s; P type: 120% rated current

60s;150% rated current 3s.

⚫Torque Boost:Auto boost; Manual boost 0.1%~30.0%

⚫DC braking:0.00Hz~maximum frequency (DC braking frequency); 0.0s~36.0s(Braking time);

0.0%~100.0%( Braking trigger current value)

Individualized Functions

⚫Built-in Simple PLC / Multiple Speeds:It realizes up to 16 speeds via the simple PLC function or

combination of DI terminal states.

⚫Built-in PID:It realizes closed loop control system easily.

⚫Auto voltage regulation (AVR): It can keep constant output voltage automatically when the mains

voltage fluctuation

⚫Overvoltage/ Overcurrent Stall Control:The current and voltage are limited automatically during the

running process so as to avoid frequently tripping due to overvoltage / over current.

⚫Rapid Current Limit: To avoid frequently over current faults of the frequency inverter.

⚫Torque Limit and Control:It can limit the torque automatically and prevent frequently over current

tripping during the running process. Torque control can be implemented in the VC mode.

⚫High Performance:Control of asynchronous motor is implemented through the high-performance current

vector control technology.

⚫Virtual I/O:Five groups of virtual DI/DO can realize simple logic control.

⚫Timing Control:Time range: 0.0~6500.0 minutes

⚫Motor Overheat Protection:The optional I/O extension card enables AI3 to receive the motor

temperature sensor input (PT100, PT1000) so as to realize motor overheat protection.

⚫Multiple Encoder Types:It supports differential encoder, open-collector encoder

⚫Protection Mode:Motor short-circuit detection after power-on, input/output phase loss protection, over

current and overvoltage protection, less voltage protection, overheat protection and overload protection,etc

External Interface

⚫Running Command Giving:key panel; Control terminals; Serial communication port; You can switch

between these giving in various ways.

⚫Frequency Giving:There are 10 kinds frequency giving: digital setting, analog voltage setting, analog

current setting, pulse setting and serial communication port setting.

⚫Programmable Digital Input: 6 digital input (DI) terminals, one of which supports up to 100 kHz

high-speed pulse input

⚫Programmable Analog Input: 3 analog input (AI) terminals, AI1,AI2 support 0V~10 V or 0mA~20mA

input,AI3 support -10V~+10V

⚫Programmable Open Collector Output: 1 FMP output terminal, that supports 0–100 kHz square wave

signal output (Can be used as DO output)

⚫Programmable Analog Output:2 analog output (AO) terminals,both of them supports 0mA~20mA

current output and 0V~10V voltage output.

⚫Relay Output: 2 relay output terminal (2.2KW and below only have 1 relay output terminal)

Environment

⚫Installation Location:Indoor, no direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapour,

drip or salt.

⚫Altitude:Lower than 1000m

⚫Ambient Temperature:-10°C~ +40°C (de-rated if the ambient temperature is between 40°C and 50°C)

⚫Humidity:Less than 95%RH, without condensing

⚫Vibration:Less than 5.9 m/s2 (0.6 g)

⚫Storage Temperature:-20°C ~ +60°C

EM15 User’s Manual 2. Product Information

7

2.3 Model and Technical data

Model

Power Capacity

(KVA)

Input Current

(A)

Output Current

(A)

Adaptable Motor

KW

HP

Single phase 220V 50/60Hz

EM15-G1-d75

1.5

8.2

4

0.75

1

EM15-G1-1d5

3

14

7

1.5

2

EM15-G1-2d2

4

23

9.6

2.2

3

Three phase 220V 50/60Hz

EM15-G2-d75

3

5

3.8

0.75

1

EM15-G2-1d5

4

5.8

5.1

1.5

2

EM15-G2-2d2

5.9

10.5

9

2.2

3

EM15-G2-004

8.9

14.6

17

3.7

5

EM15-G2-5d5

17

26

25

5.5

7.5

EM15-G2-7d5

21

35

32

7.5

10

EM15-G2-011

30

46.5

45

11

15

EM15-G2-015

40

62

60

15

20

EM15-G2-018

57

76

75

18.5

25

EM15-G2-022

69

92

91

22

30

EM15-G2-030

85

113

112

30

40

EM15-G2-037

114

157

150

37

50

EM15-G2-045

134

180

176

45

60

EM15-G2-055

160

214

210

55

75

EM15-G2-075

231

307

304

75

100

Three phase 380V 50/60Hz

EM15B-G3-d75/P3-1d5

1.5/3

5/5.8

2.1/3.8

0.75/1.5

1/2

EM15B-G3-1d5/P3-2d2

3/4

5.8/10.5

3.8/5.1

1.5/2.2

2/3

EM15B-G3-2d2/P3-004

4/5.9

10.5/14.6

5.1/9

2.2/3.7

3/5

EM15-G3-004/P3-5d5

5.9/8.9

14.6/20.5

9/13

3.7/5.5

5/7.5

EM15-G3-5d5/P3-7d5

8.9/11

20.5/26

13/17

5.5/7.5

7.5/10

EM15-G3-7d5/P3-011

11/17

26/35

17/25

7.5/11

10/15

EM15-G3-011/P3-015

17/21

35/38.5

25/32

11/15

15/20

EM15-G3-015/P3-018

21/24

38.5/46.5

32/37

15/18.5

20/25

EM15-G3-018/P3-022

24/30

46.5/62

37/45

18.5/22

25/30

EM15-G3-022/P3-030

30/40

62/76

45/60

22/30

30/40

EM15-G3-030/P3-037

40/57

76/92

60/75

30/37

40/50

EM15-G3-037/P3-045

57/69

92/113

75/91

37/45

50/60

EM15-G3-045/P3-055

69/85

113/128

91/112

45/55

60/75

EM15-G3-055/P3-075

85/114

128/157

112/150

55/75

75/100

EM15-G3-075/P3-090

114/134

157/180

150/176

75/90

100/125

EM15-G3-090/P3-110

134/160

180/214

176/210

90/110

125/150

EM15-G3-110/P3-132

160/192

214/256

210/253

110/132

150/200

EM15-G3-132/P3-160

192/231

256/307

253/304

132/160

200/250

EM15-G3-160/P3-200

231/250

307/385

304/377

160/200

250/280

EM15-G3-200/P3-220

250/280

385/430

377/426

200/220

280/300

2. Product Information EM15 User’s Manual

8

Model

Power Capacity

(KVA)

Input Current

(A)

Output Current

(A)

Adaptable Motor

KW

HP

EM15-G3-220/P3-250

280/355

430/468

426/465

220/250

300/370

EM15-G3-250/P3-280

355/396

468/525

465/520

250/280

370/400

EM15-G3-280/P3-315

396/445

525/590

520/585

280/315

400/420

EM15-G3-315/P3-355

445/500

590/665

585/650

315/355

420/500

EM15-G3-355

500

665

650

355

500

EM15-G3-400

560

785

725

400

530

EM15-G3-450

630

883

820

450

600

EM15-G3-500

800

920

860

500

660

Three phase 480V 50/60Hz

EM15B-G4-d75/P4-1d5

1.5/3

5/5.8

2.1/3.8

0.75/1.5

1/2

EM15B-G4-1d5/P4-2d2

3/4

5.8/10.5

3.8/5.1

1.5/2.2

2/3

EM15B-G4-2d2/P4-004

4/5.9

10.5/14.6

5.1/9

2.2/3.7

3/5

EM15-G4-004/P4-5d5

5.9/8.9

14.6/20.5

9/13

3.7/5.5

5/7.5

EM15-G4-5d5/P4-7d5

8.9/11

20.5/26

13/17

5.5/7.5

7.5/10

EM15-G4-7d5/P4-011

11/17

26/35

17/25

7.5/11

10/15

EM15-G4-011/P4-015

17/21

35/38.5

25/32

11/15

15/20

EM15-G4-015/P4-018

21/24

38.5/46.5

32/37

15/18.5

20/25

EM15-G4-018/P4-022

24/30

46.5/62

37/45

18.5/22

25/30

EM15-G4-022/P4-030

30/40

62/76

45/60

22/30

30/40

EM15-G4-030/P4-037

40/57

76/92

60/75

30/37

40/50

EM15-G4-037/P4-045

57/69

92/113

75/91

37/45

50/60

EM15-G4-045/P4-055

69/85

113/128

91/112

45/55

60/75

EM15-G4-055/P4-075

85/114

128/157

112/150

55/75

75/100

EM15-G4-075/P4-090

114/134

157/180

150/176

75/90

100/125

EM15-G4-090/P4-110

134/160

180/214

176/210

90/110

125/150

EM15-G4-110/P4-132

160/192

214/256

210/253

110/132

150/200

EM15-G4-132/P4-160

192/231

256/307

253/304

132/160

200/250

EM15-G4-160/P4-200

231/250

307/385

304/377

160/200

250/280

EM15-G4-200/P4-220

250/280

385/430

377/426

200/220

280/300

EM15-G4-220/P4-250

280/355

430/468

426/465

220/250

300/370

EM15-G4-250/P4-280

355/396

468/525

465/520

250/280

370/400

EM15-G4-280/P4-315

396/445

525/590

520/585

280/315

400/420

EM15-G4-315/P4-355

445/500

590/665

585/650

315/355

420/500

EM15-G4-355

500

665

650

355

500

EM15-G4-400

560

785

725

400

530

EM15-G4-450

630

883

820

450

600

EM15-G4-500

800

920

860

500

660

EM15 User’s Manual 2. Product Information

9

2.4 Product appearance and installation dimension

2.4.1 Appearance and Installation Hole Dimension (mm)

Diagram 2-3 Three phase 0.75~2.2kW Wall-mounted installation dimensions

Matching inverter

Appearance and installing dimension (Unit: mm)

Voltege

Power Range

W

W1

H

H1

D

d

1PH 220V

0.75~2.2kW

101

90

152

141

132

Φ4

3PH 220V

0.75~2.2kW

3PH 380V

0.75~2.2 kW

3PH 480V

0.75~2.2 kW

Diagram 2-4 Three phase 4~22kW Wall-mounted installation dimensions

Matching inverter

Appearance and installing dimension (Unit: mm)

Voltege

Power Range

W

W1

H

H1

D

d

3PH 380V

4~5.5kW

120

108

205

195

166

Φ4.5

3PH 480V

4~5.5kW

3PH 220V

4~5.5kW

162

148

250

238

191

Φ5.5

3PH 380V

7.5~11kW

3PH 480V

7.5~11kW

3PH 220V

7.5~11kW

223

207

323

307

207

Φ5.5

3PH 380V

15~22kW

3PH 480V

15~22kW

2. Product Information EM15 User’s Manual

10

Diagram 2-5 Three phase 30~500kW Wall-mounted installation dimensions

Matching inverter

Appearance and installing dimension (Unit: mm)

Voltege

Power Range

W

W1

H

H1

D

d

3PH 220V

15~18.5kW

300

220

540

500

240

Φ7

3PH 380V

30~37kW

3PH 480V

30~37kW

3PH 220V

22~30kW

340

260

575

545

270

Φ10

3PH 380V

45~55kW

3PH 480V

45~55kW

3PH 220V

37~45kW

410

260

610

580

285

Φ12

3PH 380V

75~90kW

3PH 480V

75~90kW

3PH 220V

55kW

475

320

720

695

335

Φ12

3PH 380V

110~132kW

3PH 480V

110~132kW

3PH 220V

75kW

550

360

880

825

360

Φ12

3PH 380V

160~220kW

3PH 480V

160~220kW

3PH 380V

250~315kW

670

360

1040

985

415

Φ12

3PH 480V

250~315kW

3PH 380V

355~500kW

815

600

1300

1235

445

Φ12

3PH 480V

355~500kW

EM15 User’s Manual 2. Product Information

11

Diagram 2-6 Three phase 160~500kW Floor-mounted installation dimensions

Matching inverter

Appearance and installing dimension (Unit: mm)

Voltege

Power Range

W

W1

H

D

D1

d

3PH 220V

75kW

535

438

1397

370

252

Φ14

3PH 380V

160~220kW

3PH 480V

160~220kW

3PH 380V

250~315kW

650

558

1552

415

297

Φ14

3PH 480V

250~315kW

3PH 380V

355~500kW

815

722

1832

445

306

Φ14

3PH 480V

355~500kW

2.4.2Appearance and installation dimension of external keypad (keypad tray)

Diagram 2-7Appearance and installation dimension of small size external keypad (keypad tray)

Diagram 2-8Appearance and installation dimension of big size external keypad (keypad tray)

2. Product Information EM15 User’s Manual

12

2.5 Daily maintenance of frequency inverters

2.5.1 Daily maintenance

Due to the influence of temperature, humidity, dust and vibration, it will lead to poor heat dissipation and

component aging of frequency inverter, and results in potential failure or reducing the service life of frequency

inverter. Therefore, it is necessary to do daily and regular maintenance of the frequency inverter.

Daily check items:

1. Check if the frequency inverter sound is normal during the running of the motor;

2. Check if there is a vibration during the running of the motor;

3. Check whether the installation environment of frequency inverter has changed;

4. Check if the cooling fan of frequency inverter is working correctly, the cooling air duct is clear;

5. Check if the frequency inverter is overheating;

6. Make sure that the frequency inverter should always be kept in a clean state;

7. Clear up effectively the dust on the surface of the frequency inverter, prevent the dust from entering into the

inside of the frequency inverter, especially for the metal dust;

8. Clear up effectively the oil and dust on the cooling fan of frequency inverter.

2.5.2 Regular inspection

Please regularly check frequency inverter, especially for the difficult checking place during running.

Regular inspection items:

1. Check the air duct and clear up regularly;

2. Check if there are any loose screws;

3. Check if the inverter has been corroded;

4. Check whether the wiring terminals show signs of arcing.

Note: When using the megger(please use the DC 500V meg ohm meter) to measure the insulation resistance, you

shall disconnect the main circuit to the frequency inverter. Do not use the insulation resistance meter to test the

control circuit. Do not to do the high voltage test (It has been done when the frequency inverter producing in

factory.)

2.5.3 Replacement of wearing parts

The vulnerable parts of frequency inverter include the cooling fan and filter electrolytic capacitor, its service life is

closely related to the using environment and maintenance status. The general service life is:

Part Name

Service Life

Fan

3 to 4 Years

Electrolytic capacitor

5 to 6 Years

The user can confirm the replace time according to the running time.

1. Possible reasons for the damage of cooling fan: bearing wear and blade aging. Distinguish standard: Any

cracks in the fan blade, any abnormal vibration sound during the starting of frequency inverter.

2. Possible reasons for the damage of filting electrolytic capacitor: poor quality of the input power supply, the

environment temperature is higher, the load change frequently and the electrolyte aging. Distinguish standard:

Any leakage of its liquid, if the safety valve is protruding, please test capacitor electrostatic capacitance and

insulation resistance.

2.5.4 Storage of the frequency inverter

After buying the frequency inverter, users shall pay attention to the temporary and long-term storage as following:

1. Store the frequency inverter in the original packaging;

EM15 User’s Manual 2. Product Information

13

2. Long-term storage can lead to the degradation of electrolytic capacitors, and must ensure to power on for once

within 2 years. And the power-on time is at least 5 hours. The input voltage must slowly rise to the rating by

using the voltage regulator.

2.6 Selection Guide of braking component

Table 2-5 is the recommended value of braking resistor, users can select the different resistance value and power

according to the actual situation,(but the resistance value must not be less than the recommended value in the table,

and the power can be bigger.) The selection of braking resistance need to be confirmed according to the power

that the motor generated in the practical application systems, and is relevant to the system inertia, deceleration

time, the energy of the potential energy load, needs customers to choose according to actual situation. The greater

the inertia and the shorter deceleration time is needed more frequently braking, so the braking resistor needs the

one with bigger power but smaller resistance value.

2.6.1 Selection of braking resistance value

When braking, almost all the regenerated energy of motor is consumed by the braking resistor.

According to the formula: U * U/R = Pb

In the formula:

U --- The braking voltage when the system brake stably (different system is different, for the 380VAC system

generally take 700V)

R - Braking resistor value

Pb –Power of braking(W)

2.6.2 Selection power of braking resistor

In theory the power of braking resistor is consistent with the braking power, but it need to be taken into

consideration that the braking resistor power will derate to 70%.

According to the formula: 0.7*Pr=Pb*D

In this formula:

Pr----Power of resistor

D---- Braking proportion (the proportion that the regeneration process accounts for the whole process)

Elevator---- 20%~30%

Uncoiling and coiling machine---- 20%~30%

Centrifugal machine---- 50%~60%

Occasionally braking load---- 5%

Other machine generally-----10%

Table 2-5 EM15 Inverter braking components selection table

Inverter Power

Recommend

power of braking

resistor

Recommend

resistance value of

braking resistor

Braking

unit

Remarks

Single phase 220V

EM15-G1-d75

80W

≥ 150Ω

Built-in as

standard

No special

instructions

EM15-G1-1d5

100W

≥ 100Ω

EM15-G1-2d2

100W

≥ 70Ω

Three phase 220V

EM15-G2-d75

150W

≥ 110Ω

Built-in as

standard

No special

instructions

EM15-G2-1d5

250W

≥ 100Ω

2. Product Information EM15 User’s Manual

14

Inverter Power

Recommend

power of braking

resistor

Recommend

resistance value of

braking resistor

Braking

unit

Remarks

EM15-G2-2d2

300W

≥ 65Ω

EM15-G2-004

400W

≥ 45Ω

EM15-G2-5d5

800W

≥ 22Ω

EM15-G2-7d5

1000W

≥ 16Ω

EM15-G2-011

1500W

≥ 11Ω

External

No special

instructions

EM15-G2-015

2500W

≥ 8Ω

EM15-G2-018

3.7 kW

≥ 8.0Ω

EM15-G2-022

4.5 kW

≥ 8Ω

EM15-G2-030

5.5 kW

≥ 4Ω

EM15-G2-037

7.5 kW

≥ 4Ω

EM15-G2-045

4.5 kW×2

≥ 4Ω×2

EM15-G2-055

5.5 kW×2

≥ 4Ω×2

EM15-G2-075

16kW

≥ 1.2Ω

Three phase 380V/480V

EM15B-G3[4]-d75/P3[4]-1d5

150W

≥ 300Ω

Built-in as

standard

No special

instructions

EM15B-G3[4]-1d5/P3[4]-2d2

150W

≥ 220Ω

EM15B-G3[4]-2d2/P3[4]-004

250W

≥ 200Ω

EM15-G3[4]-004/P3[4]-5d5

300W

≥ 130Ω

EM15-G3[4]-5d5/P3[4]-7d5

400W

≥ 90Ω

EM15-G3[4]-7d5/P3[4]-011

500W

≥ 65Ω

EM15-G3[4]-011/P3[4]-015

800W

≥ 43Ω

EM15-G3[4]-015/P3[4]-018

1000W

≥ 32Ω

EM15-G3[4]-018/P3[4]-022

1300W

≥ 25Ω

EM15-G3[4]-022/P3[4]-030

1500W

≥ 22Ω

EM15-G3[4]-030/P3[4]-037

2500W

≥ 16Ω

External

No special

instructions

EM15-G3[4]-037/P3[4]-045

3.7 kW

≥ 16.0Ω

EM15-G3[4]-045/P3[4]-055

4.5 kW

≥ 16Ω

EM15-G3[4]-055/P3[4]-075

5.5 kW

≥ 8Ω

EM15-G3[4]-075/P3[4]-090

7.5 kW

≥ 8Ω

EM15-G3[4]-090/P3[4]-110

4.5 kW×2

≥ 8Ω×2

EM15-G3[4]-110/P3[4]-132

5.5 kW×2

≥ 8Ω×2

EM15-G3[4]-132/P3[4]-160

6.5 kW×2

≥ 8Ω×2

EM15-G3[4]-160/P3[4]-200

16kW

≥ 2.5Ω

EM15-G3[4]-200/P3[4]-220

20 kW

≥ 2.5Ω

EM15-G3[4]-220/P3[4]-250

22 kW

≥ 2.5Ω

EM15-G3[4]-250/P3[4]-280

12.5 kW×2

≥ 2.5Ω×2

EM15-G3[4]-280/P3[4]-315

14kW×2

≥ 2.5Ω×2

EM15-G3[4]-315/P3[4]-355

16kW×2

≥ 2.5Ω×2

EM15-G3[4]-355

17kW×2

≥ 2.5Ω×2

EM15-G3[4]-400

14 kW×3

≥ 2.5Ω×3

EM15-G3[4]-450

16 kW×3

≥ 2.3Ω×3

EM15 User’s Manual 2. Product Information

15

2.6.3 Braking resistor connection description

The braking resistor connection of EM15 series frequency inverter is showed as below:

Inverter

P+

PB

Braking Resistor Inverter

P+

P-

Braking Resistor

Braking

Unit

Diagram 2-9 Braking resistor connection scheme

This manual suits for next models

74

Table of contents

Other Emheater DC Drive manuals

Popular DC Drive manuals by other brands

Raymarine

Raymarine SmartPilot X-10 installation guide

IBM

IBM 9348 Service information

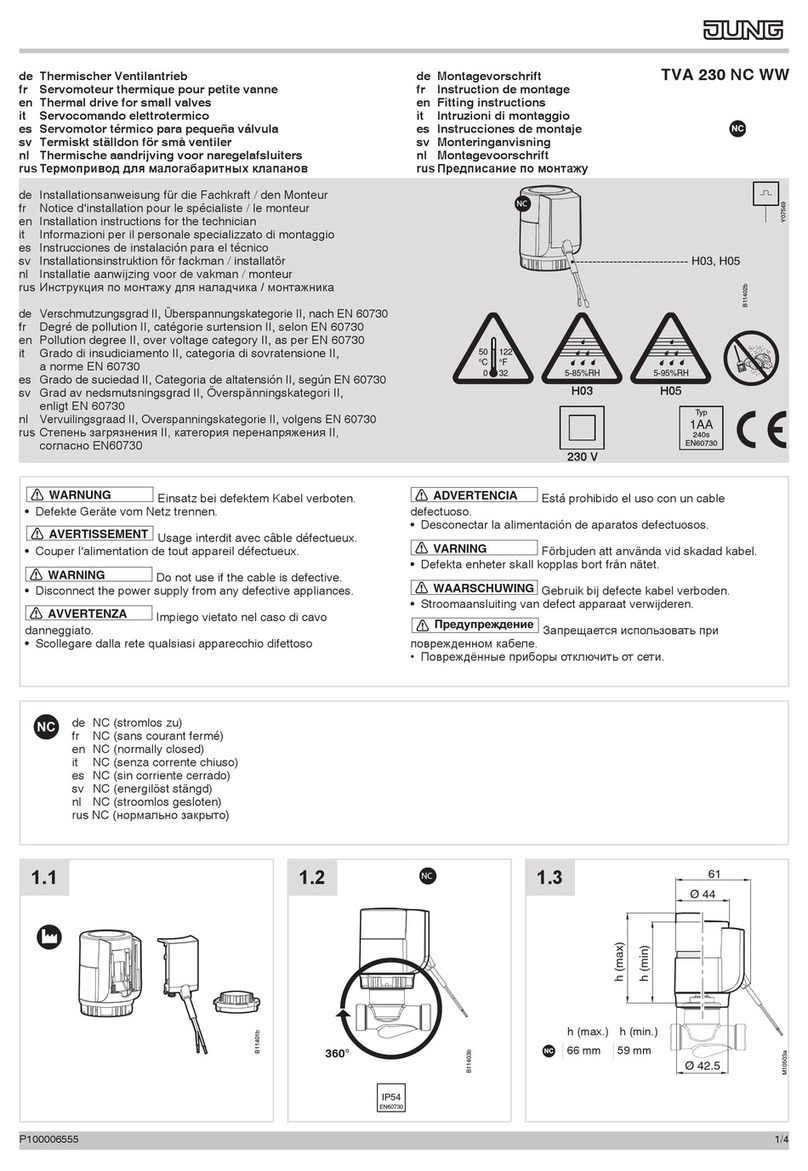

Jung

Jung TVA 230 NC WW Fitting instructions

D+H

D+H FRA 11-BSY Plus Original instructions

YASKAWA

YASKAWA MECHATROLINK-III installation manual

Emotron

Emotron FlowDrive Emotron FLD48 Installation & Getting started instruction