MODELS

VCDK090C • VCDK130C • VCDK170C

WARRANTY

3

Seller warrants products manufactured by it and supplied here-

under to be free from defects in materials and workmanship under

normal use and proper maintenance for a period of twelve months

from date of shipment. If within such period any such products

shall be proved to Seller’s reasonable satisfaction to be defective,

such products shall be repaired or replaced at Seller’s option.

Seller's obligation and Buyer’s exclusive remedy hereunder shall

be limited to such repair and replacement and shall be condi-

tioned upon Seller’s receiving written notice of any alleged

defects no later than 10 days after its discovery within the war-

ranty period and, at Seller’s option, the return of such products to

Seller, f.o.b. its factory, when such return is feasible. Seller

reserves the right to satisfy its warranty obligation in full by reim-

bursing Buyer for all payments it makes hereunder, and Buyer

shall thereupon return the products to Seller. Seller shall have the

right to remedy such defects.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND

IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WAR-

RANTIES (EXCEPT TO TITLE) INCLUDING BUT NOT LIMITED

TO IMPLIED WARRANTIES OF MERCHANTABILITY FITNESS

FOR A PARTICULAR PURPOSE, PERFORMANCE, OR OTH-

ERWISE, and in no event shall the Seller be liable for claims

(based upon breach of express or implied warranty, negligence,

product liability, or otherwise) for any other damages, whether

direct, immediate, incidental, foreseeable, consequential, or spe-

cial.

USE AND CARE

Ventilator is designed for continuous operation. If desired, it may

be controlled using an on/off switch or a solid-state, variable

speed control. Follow wiring instructions packed with control,

and adhere to all local and state codes, and the National

Electrical Code.

To clean blower assembly: Remove grille, disassemble two

cabinet halves, unplug blower from housing, remove blower

mounting nuts, and carefully remove blower from housing. Use

appropriate vacuum attachment or a soft cloth and mild soap or

detergent to clean blower discharge area and wheel. DO NOT

ALLOW WATER TO ENTER THE MOTOR. Make sure blower

assembly is completely dry before reinstalling.

Motor is permanently lubricated. Do not oil or disassemble

motor.

WARNING: To reduce the risk of electric shock,

disconnect from power supply before servicing.

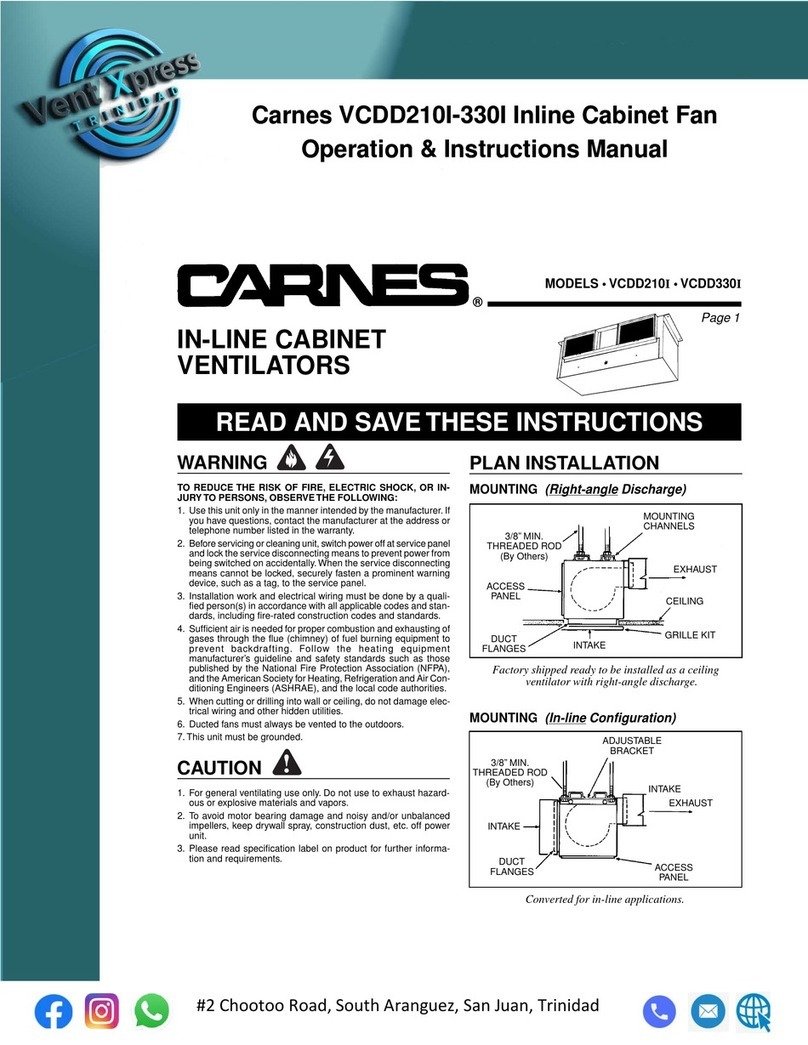

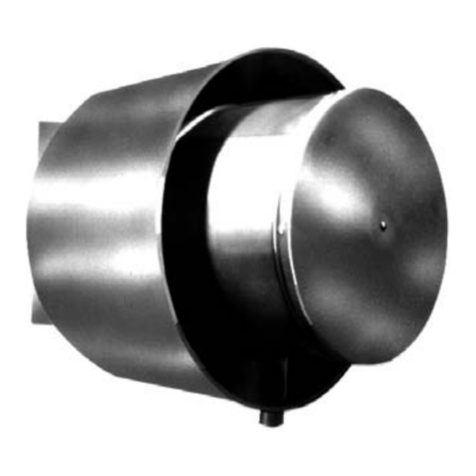

DUCTING

(Vertical blower discharge)

ROOF CAP

12”

ROUND

DUCT

9-3/8” x 12-3/4”

TO 10” ROUND

TRANSITION

Typical ductwork connection to a ventilator converted to

vertical discharge.

Two ways to connect ductwork to a factory-shipped unit.

DUCTING

(Horizontal blower discharge)

9-3/8” x 12-3/4” TO

12” ROUND

TRANSITION

12” ROUND

ELBOW WALL

CAP

12”

ROUND

DUCT

ROOF CAP