FORM 1415

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

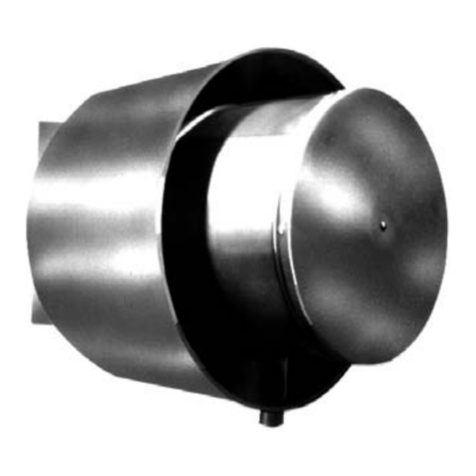

CENTRIFUGAL UPBLAST ROOF EXHAUSTERS FOR

COMMERICAL KITCHEN APPLICATIONS

MODEL VRBK - BELT DRIVEN

CAUTION!

DO NOT INSTALL, USE OR OPERATE THIS EQUIPMENT UNTIL THIS

MANUAL HAS BEEN READ AND UNDERSTOOD. READ AND SAVE THESE INSTRUCTIONS FOR FUTURE USE.

RECEIVING, HANDLING AND STORAGE

1. Handle the fan with care. Avoid severe jarring or dropping of the unit.

2. Carefully inspect the unit for damage upon delivery. If the unit has been damaged in transit it is the responsibility

of the recipient to make all claims against the carrier.

3. Provide adequate, protected storage prior to installation.

INSTALLATION

1. Upon unpacking, inspect the unit for any damage that may have occurred in transit. Check also for loose or

missing parts.

2. CAUTION! This fan contains rotating parts and requires electrical service. Appropriate safety precautions

should be taken during installation, operation and maintenance.

3. WARNING! Do not install or operate this fan in environment or atmosphere where combustible or flammable

materials, gasses or fumes are present, unless it has been specifically designed and manufactured for use in that

environment. Explosion or Fire could result!

4. This ventilator requires a minimum of four (4) mounting fasteners, of the appropriate size and type in order to be

securely fastened to the roof curb. Be sure to use an approved sealant between the fan and curb to prevent

leaking.

5. CAUTION! All electrical work must be done in accordance with local and/or national electrical code as

applicable. If you are unfamiliar with methods of installing electrical wiring, secure the services of a qualified

electrician.

6. WARNING! This product must be grounded.

7. DANGER! Make sure power is turned off and locked in the OFF position at the service entrance before

installing, wiring or servicing fan.

8. CAUTION! Before wiring the motor, check the supply voltage against the motor nameplate voltage. High

or low voltage can damage the motor and void the motor warranty.

9. Power should be routed through the conduit openings provided.

10. Access to the motor compartment is possible by either removing the motor cover or motor tube/motor cover

assembly.

11. WARNING! Be sure to keep all wiring clear of rotating or moving parts.

12. WARNING! Before starting the fan, turn the wheel to assure it rotates freely. If needed, adjust the wheel/

shaft/bearing/motor position as required to achieve necessary clearances.

13. CAUTION! On belt drive units assure belts are tensioned and aligned properly. (See Maintenance section.)

14. WARNING! Check all set screws and keys. Tighten as necessary prior to fan startup. Do not over torque

15. Remount motor cover/motor tube, do not over torque fasteners (30 in. - lb. maximum)

FORM 1415, Page 1

CARNES COMPANY 448 S. Main St., P. O. Box 930040, Verona, WI 53593-0040 Phone: (608)845-6411 Fax: (608)845-6470 www.carnes.com