Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

3

Routine Maintenance

Daily

Inspect the unit:

•

power cord is not broken, frayed or worn, and the plug is fully

engaged at the wall outlet

•

casters are locked

•

red filter/obstruction indicator is notilluminated

•

unit operates without excessive vibration or unusual noises

•

flexible exhaust ducting (if used) is not kinked or damaged, and

securely attached at bothends

Cleaning

Routinely clean any dust and contaminants from the exterior of the unit

and power cord with a mild cleaner. Do not use excessive liquid.

Decontaminate as necessary with a facility- and EPA-approved

disinfectant.

Filter Replacement

NOTE: Before replacing filters, check to make sure there is nothing

impeding the airflow into the unit. Check under the unit for paper,

rubbish, etc., that may be trapped on the intake side.

7.

Plug in the unit and rock the power switch up to the ON position. The

red indicator light should extinguish within a few seconds. If it does not,

then the HEPA filter needs to bereplaced.

HEPA Filter

The HEPA filter, when used in a negative air machine, is rated for

approximately 40,000 hours of operation, or 4 years, under normal

conditions and with recommended replacement of the pre-filter (air

scrubber use will reduce filter life). If the red indicator light is

illuminated, and did not extinguish after replacing the pre-filter, then the

next step is to replace the main HEPA filter. For residential use, call your

dealer to do this procedure. For healthcare facilities, follow these steps

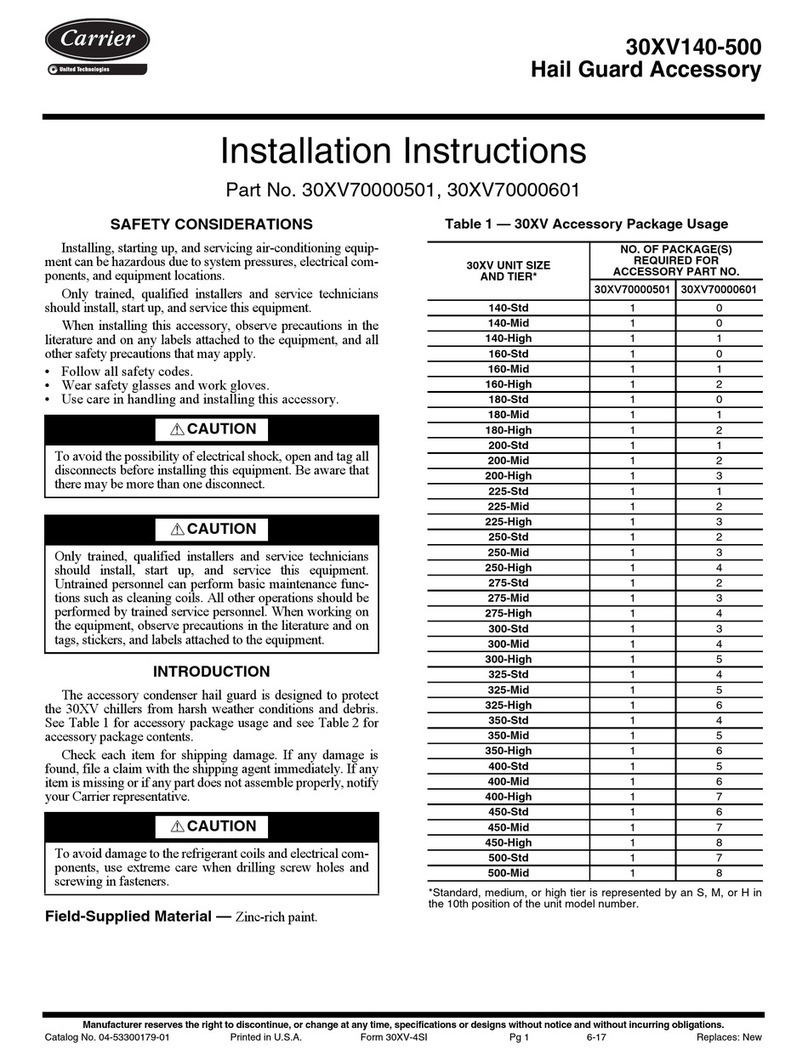

(Fig. 5):

1.

Move the power switch to the OFFposition.

2.

Unplug the unit from the walloutlet.

3.

Listen to make sure the blower wheel has stopped spinning, and

remove the bottom front door.

4.

Put on Personal ProtectiveEquipment.

5.

Remove the pre-filter from theunit.

6.

Remove the bottom nuts from the all-thread bars on both sides

(four nutstotal).

7.

Remove the HEPA filter and immediately put it inside an approved

containment bag. Dispose per facility guidelines for hazardous

materials.

8.

Position the new HEPA filter into the unit with the gasket on the

filter facing up, on the discharge side of the filter. Make sure the

HEPA filter is centered and the edges align with the brackets on the

top side and each side for a completeseal.

9.

Re-install the bottom supports and attach the bottomnuts.

10.

Tighten the nuts equally until the filter is held securely in place, and

ensure the top HEPA filter gasket is significantly compressed

against the mounting structure to assure no bypassair.

11.

Inspect the filter for a complete and tight fit. Loosen the nuts and

reposition ifnecessary.

12.

Replace thepre-filter.

13.

Replace the bottom frontdoor panel.

NOTE: If your facility already has a procedure in place for replacing

filters, follow your procedure. If guidance is needed then follow these

instructions.

Pre-Filter

The pre-filter should generally be replaced every 60 to 90 days.

When the red indicator light on the front panel is illuminated, the most

likely reason is that the pre-filter is clogged and needs to be replaced.

Proceed as follows (Fig. 5):

1.

Rock the green the power switch down to the OFF position.

2.

Unplug the unit from the walloutlet.

3.

Listen to make sure the blower wheel has stopped spinning, and

remove the bottom frontdoor panel.

4.

Put on Personal ProtectiveEquipment.

5.

Slide the pre-filter out of the cabinet and immediately put it inside

an approved containment bag. Dispose per facility guidelines for

hazardousmaterials.

6.

Replace the pre-filter with the same type and size (minimum

MERV 7). Note the air-flow arrows on the filter and make sure they

point up. Replace the bottom front door panel.

Fig. 5 –Filters