B

Horizontal Applications

Horizontal units are shipped with outer panels that allow for side

by side horizontal duct connections. If specified during ordering,

the unit will be shipped with the vertical duct openings blocked off

from the factory, ready for side supply installation. If the horizontal

option was not specified at time of ordering the unit, a

field-installed accessory kit is required to convert the vertical unit

into a horizontal supply configuration.

Installation of the duct block-off covers should be completed prior

to placing the unit unless sufficient side clearance is available. A

minimum of 66 in. is required between the unit and any

obstruction to install the duct block-off covers. Side supply duct

dimensions and locations are shown on Fig. 4. Connect ductwork

to horizontal duct flange connections on side of unit.

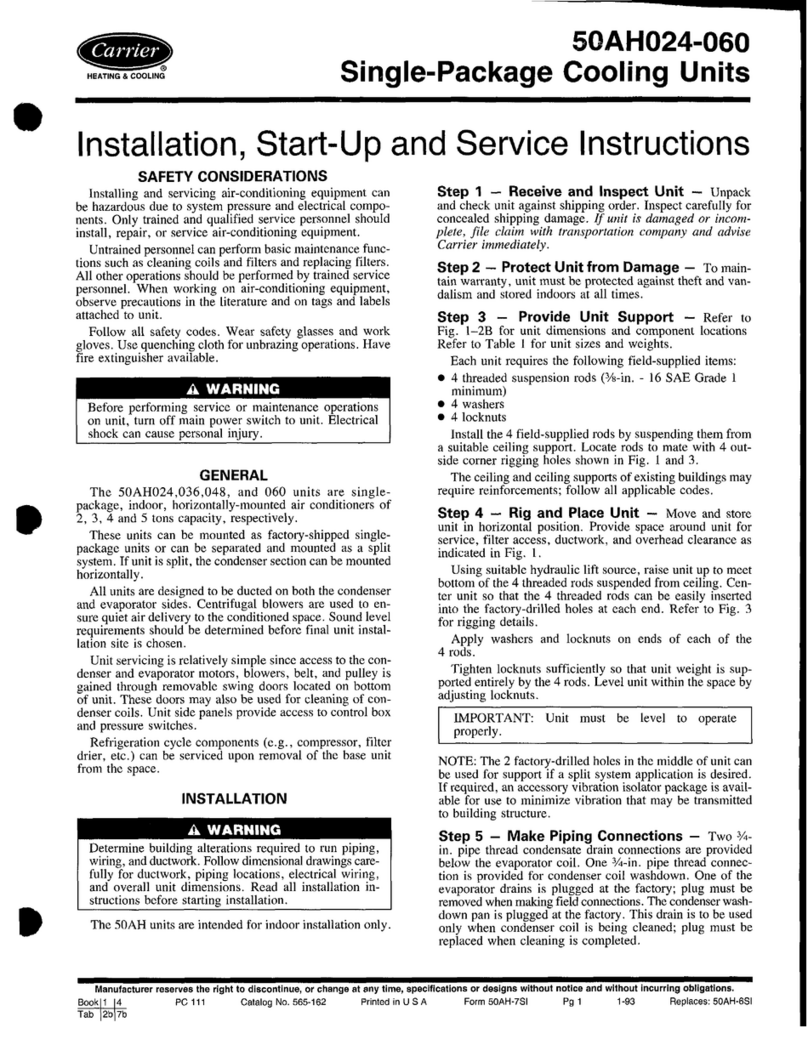

Step 6-- Trap Condensate Drain

See Fig. 9 for drain location. One 3/4-in. half coupling is provided

outside unit evaporator section for condensate drain connection. A

trap at least 4-in. deep must be used. (See Fig. 10.)

All units must have an external trap for condensate drainage. Install

a trap at least 4 in. deep and protect against freeze-up. If drain line

is installed downstream from the external trap, pitch the line away

from the unit at 1 in. per 10 ft of run. Do not use a pipe size smaller

than the unit connection.

Step 7-- Make Electrical Connections

Field Power Supply

Unit is factory wired for voltage shown on unit nameplate. Be sure

to check for correct voltage.

When installing units, provide disconnect per NEC (National

Electrical Code) of adequate size (MOCP [Maximum

Overcurrent protection] of unit is on the informative plate). (See

Tables 4 and 5.) All field wiring must comply with NEC and local

codes. Size wire based on MCA (Minimum Circuit Amps) on the

unit informative plate. See Fig. 11 for power wiring connections to

the unit power terminal block and equipment grounds.

Route power and ground lines through control box end panel or

unit basepan (see Fig. 4) to connections as shown on unit wiring

diagram and Fig. 12.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit.

The correct power phasing is critical to the operation of the

scroll compressors. An incorrect phasing will result in an

alarm being generated and compressor operation lockout.

Should this occur, power phase correction must be made to

the incoming power.

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in electrical

shock, fire, or death.

The cabinet MUST have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground

may consist of electrical wire connected to unit ground

lug in control compartment, or conduit approved for

electrical ground when installed in accordance with

NEC, ANSI/NFPA (American National Standards

Institute/National Fire Protection Association), latest

edition, and local electrical codes.

Field wiring must conform to temperature limitations for type "T"

wire. All field wiring must comply with NEC and local

requirements.

Operating voltage to compressor must be within voltage range

indicated on unit nameplate. On 3-phase units, voltages between

phases must be balanced within 2%.

Unit failure as a result of operation on improper line voltage or

excessive phase imbalance constitutes abuse and may cause

damage to electrical components.

Field Control Wiring

Unit can be controlled with aCarrier-approved accessory

thermostat. Install thermostat according to the installation

instructions included with accessory. Locate thermostat assembly

or space temperature sensor on a solid interior wall in the

conditioned space to sense average temperature.

Route thermostat cable or equivalent single leads of colored wire

from subbase terminals through conduit into unit to low-voltage

connections as shown on unit label wiring diagram and in Fig. 12.

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American

Wire Gauge) insulated wire (35°C minimum). For 50 to 75 ft, use

no. 16 AWG insulated wire (35°C minimum). For over 75 ft, use

no. 14 AWG insulated wire (35°C minimum). All wire larger than

no. 18 AWG cannot be directly connected at the thermostat and

will require a junction box and splice at the thermostat.

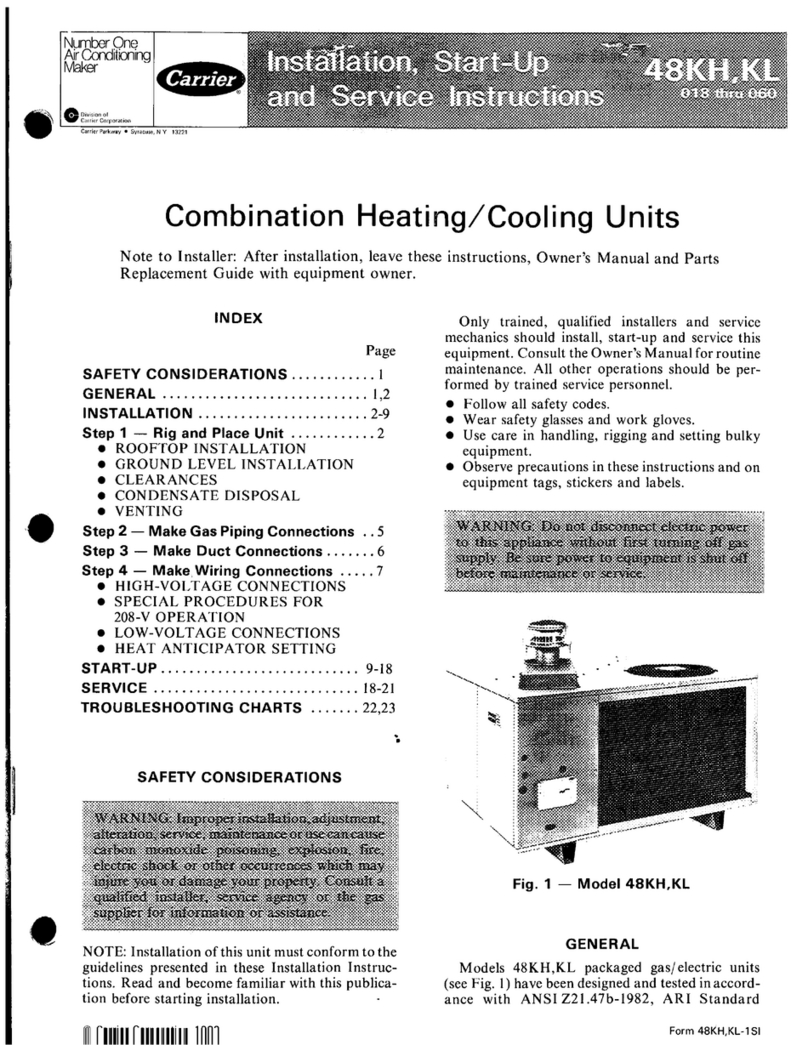

-DAMPER MOTOR

ACCESS COVER

3/4" 47-1/2 --

DRAIN CONNECTION [1208]

,_ 5-1/4

[132] I _

SUPPLY RETURN

AIR AIR

Fig. 9 - Condensate Drain Details

C06282

1OoNFETJN_)FP_IRE \ Ep_AI_LE ' I ' _

OPEN II I/

VENT t[II t

SEE

NOTE

....ROOF

CURB

NOTE: Trapshould bedeep enough to offsetmaximum unitstatic difference

A 4-in. trap is recommended.

C06291

Fig. 10 - Condensate Drain Piping Details

10