PF4MNA: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

5

a. If fan coil is away from wall, attach pipe strap to top of fan coil

using no. 10 self-tapping screws. Angle strap down and away

from back of fan coil, remove all slack, and fasten to wall stud of

structure using 5/16-in. lag screws. Typical both sides of fan coil.

b. If fan coil is against wall, secure fan coil to wall stud using 1/8-in

(3 mm) thick right-angle brackets. Attach brackets to fan coil

using no. 10 self-tapping screws and to wall stud using 5/16-in.

lag screws. (Fig. 8)

AIR DUCTS

Connect supply-air duct over the outside of 3/4-in (19 mm) flanges

provided on supply-air opening. Secure duct to flange, using proper

fasteners for type of duct used, and seal duct-to-unit joint. If return-air

flanges are required, install factory-authorized accessory kit.

Use flexible connectors between ductwork and unit to prevent

transmission of vibration. When electric heater is installed, use

heat-resistant material for flexible connector between ductwork and unit

at discharge connection. Ductwork passing through unconditioned space

must be insulated and covered with vapor barrier.

Units equipped with 20-30kW electric heaters require a 1-in (25 mm)

clearance to combustible materials for the first 36-in (914 mm) of supply

duct.

DUCT WORK ACOUSTICAL TREATMENT

Metal duct systems that do not have a 90 degree elbow and 10 feet of

main duct before first branch takeoff may require internal acoustical

insulation lining. As an alternative, fibrous duct work may be used if

constructed and installed in accordance with the latest edition of

SMACNA construction standard on fibrous glass ducts. Both acoustical

lining and fibrous duct work shall comply with National Fire Protection

Association as tested by UL Standard 181 for Class 1 air ducts.

ELECTRICAL CONNECTIONS

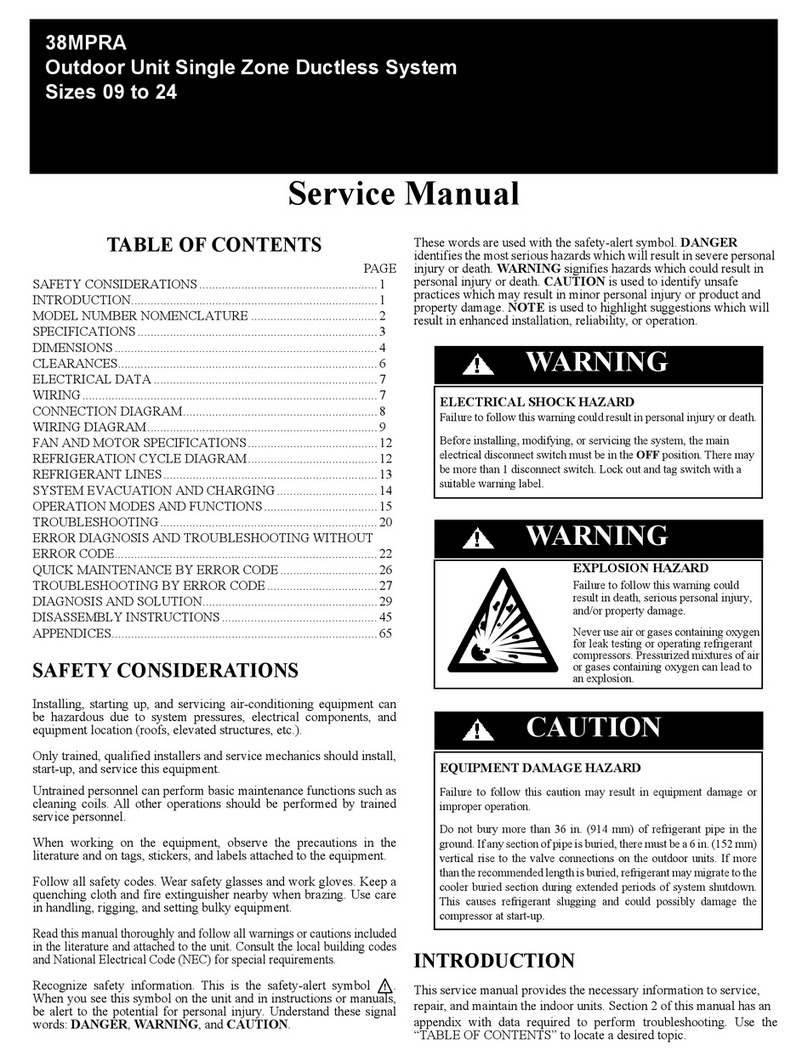

Model sizes 018, 024, 030, 036, 042, 048 and 060 from the factory

utilize a printed-circuit board (PCB) which has a low voltage circuit

protective fuse (5 amp), fan motor speed tap selection terminal (SPT),

and time delay relay (TDR) jumper. To disable the TDR feature, sever

the jumper wire JW1. (Fig. 9)

A03010

Fig. 9 – Fan Coil Printed Circuit Board for

Sizes 018, 024, 030, 036, 042, 048, 060

Model sizes 019, 025, 031, 037, 043, 049 and 061 from the factory

protect the low voltage circuit with a 5 amp automotive type fuse inline

on the wire harness. Speed selections are made at the fan motor by

selecting taps 1, 2 or 3 with the blue wire (see (MINIMUM CFM AND

MOTOR SPEED SELECTION on p7)). The motor is pre-programmed

with the time delay circuit on some of the speed taps (see section E for

clarification).

When a factory-approved accessory control package has been installed,

check all factory wiring per unit wiring diagram and inspect factory

wiring connections to be sure none were loosened in transit or

installation. If a different control package is required, see unit rating

plate.

Before proceeding with electrical connections, make certain that supply

voltage, frequency, phase, and ampacity are as specified on the unit

rating plate. See unit wiring label for proper field high- and low-voltage

wiring. Make all electrical connections in accordance with the NEC and

any local codes or ordinances that may apply. Use copper wire only.

The unit must have a separate branch electric circuit with a

field-supplied disconnect switch located within sight from, and readily

accessible from, the unit.

On units with a factory installed disconnect with pull-out removed,

service and maintenance can be safely performed on only the load side

of the control package.

LINE VOLTAGE CONNECTIONS

If unit contains an accessory electric heater, remove and discard power

plug from fan coil and connect male plug from heater to female plug

from unit wiring harness. (See Electric Heater Installation Instructions.)

For units without electric heat:

1. Connect 208/230V power leads from field disconnect to yellow and

black stripped leads.

2. Connect ground wire to unit ground lug.

NOTE: Units installed without electric heat should have a field-supplied

sheet metal block-off plate covering the heater opening. This will reduce

air leakage and formation of exterior condensation.

24V CONTROL SYSTEM

Connection To Unit

Wire low voltage in accordance with wiring label on the blower. (See

Fig. 10 through Fig. 15) Use no. 18 AWG color-coded, insulated (35°C

minimum) wire to make the low-voltage connections between the

thermostat, the unit, and the outdoor equipment. If the thermostat is

located more than 100-ft (30 m) from the unit (as measured along the

low-voltage wire), use no. 16 AWG color-coded, insulated (35°C

minimum) wire. All wiring must be NEC Class 1 and must be separated

from incoming power leads.

Refer to outdoor unit wiring instructions for any additional wiring

procedure recommendations.

®

®

CPC-E

94V-0

LR40061

HSCI

5 AMP

C

T

G

R

SPT

K1

U1

R7

R9

R10

C8

C7

R2

R3

C3

R6

R11

C4

C6

C5

R8

R5

R4

Q1

C1C2

F1

JW1

R1

Z1

D2

D1

NO

NC

FAN

RELAY

C

C

WARNING

!

ELECTRICAL SHOCK OR UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury, death,

and/or unit damage.

If a disconnect switch is to be mounted on unit, select a location where

drill and fasteners will not contact electrical or refrigeration

components.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Field wires on the line side of the disconnect found in the fan coil unit

remain live, even when the pull-out is removed. Service and

maintenance to incoming wiring cannot be performed until the main

disconnect switch (remote to the unit) is turned off.