IM-KSAIC03-03 Specifications subject to change without notice. 9

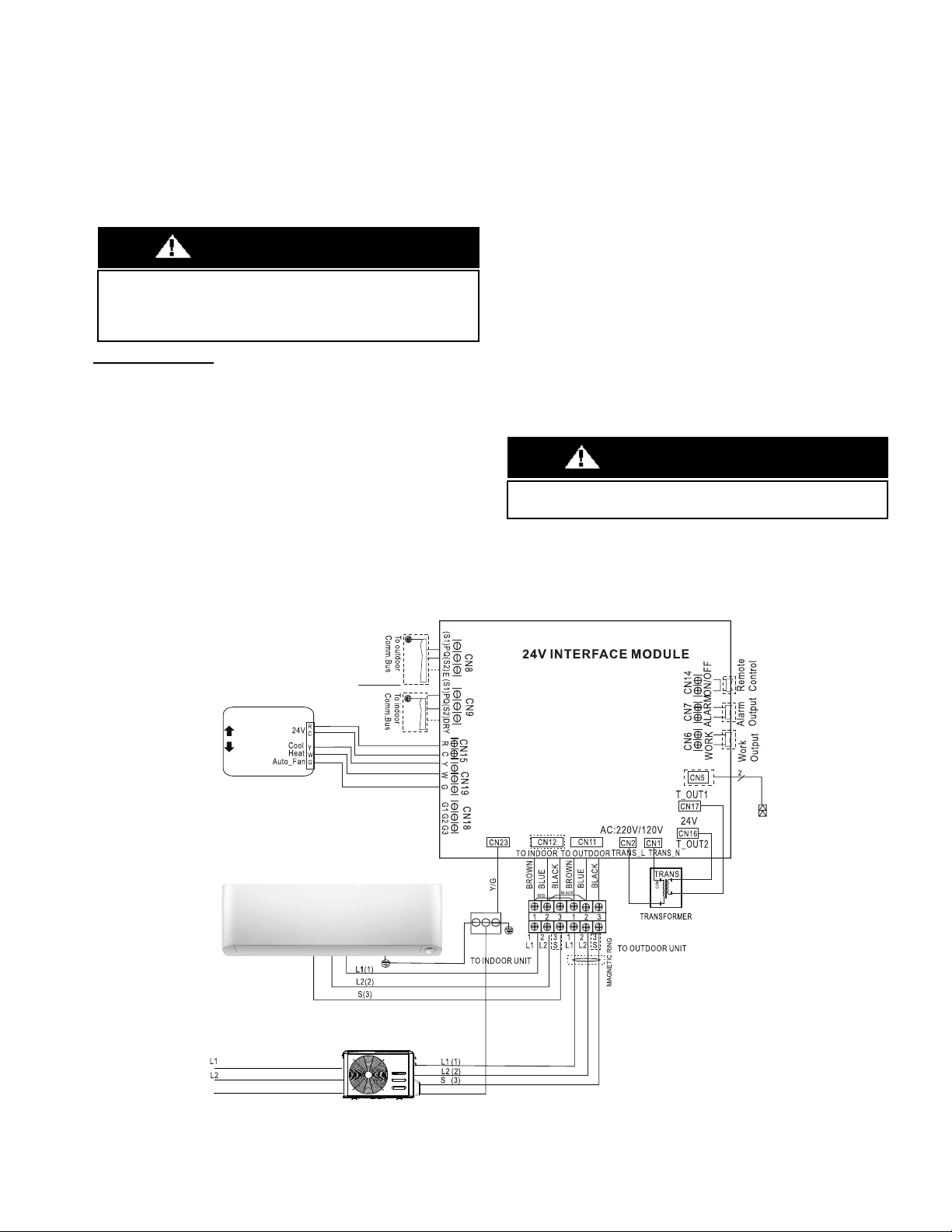

SCENARIO 5: SINGLE ZONE OUTDOOR

UNIT 38MA*R WITH APPROVED

RESIDENTIAL 24V FAN COILS FV4

For the correct combinations, review the compatibility chart in “APPENDIX

1 - COMPATIBILITY AND FAN SPEED WIRING” on page 15.

Installation Steps:

1. Remove TXV on the indoor unit.

2. Run the interconnecting piping from the outdoor unit to the indoor

unit using the outdoor piping size and brazing to the mechanical

fitting adapter that replaces the TXV (part number 40MD000003)

(available through RCD). If required, use the Bushing/Reducers

listed in “APPENDIX 2 - PIPING ADAPTER BUSHINGS/

REDUCERS” on page 16.

3. Suction and liquid refrigerant lines must be properly insulated and

separated from each other to prevent condensation and energy loss.

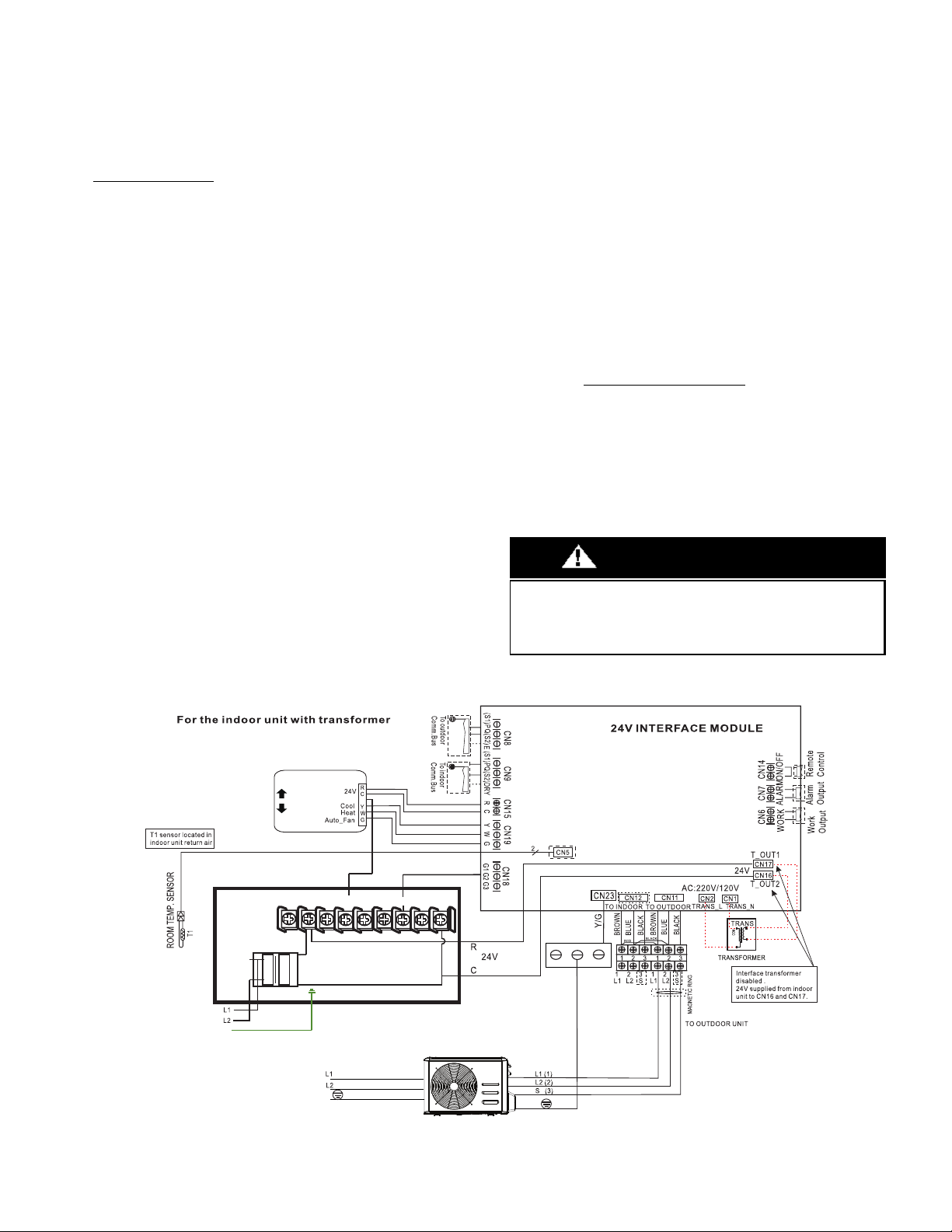

4. Disconnect and remove the 24 volt transformer from the 24 Volt

Interface. Run the 2-conductor 18 AWG cable from R and C of the

indoor unit terminal board. Connect “R” to CN17 and “C” to CN16

on the 24 Volt Interface. Be sure to connect the primary (high

voltage) wire to the correct terminal (tap) on the FV4C transformer

(see “APPENDIX 3 - FV4C TRANSFORMER” on page 16).

5. Run the interconnecting wiring (14-3 AWG stranded power cable with

ground and 600 volt insulation rating) from the outdoor unit to the 24

Volt Interface using terminal connections L1, L2, S, and G. Connect

the ground wire (G) to the grounding connection in the case. Separate

power supplies are required for the outdoor unit and the indoor unit.

6. Run the 18 AWG thermostat wiring from the thermostat terminals

to the 24 Volt Interface and connect to R and C on CN15. Also

connect Y, W, and G on CN19.

NOTE: Use an instrument size flat blade screwdriver

with a maximum blade width of 1/8” for the screw

terminals.

7. Run the 18 AWG thermostat wiring from “G1” on CN18 of the 24

Volt Interface to “G” on the indoor unit terminal board.

8. Install the T1 sensor (included with 24 Volt Interface) on CN5 of the 24 Volt

Interface and locate according to the

NOTE

addressing the indoor and

outdoor unit’s general installation in the next column.

9. Configure the dip switches on the 24V Interface for proper

operation:

For Heat Pump – all switches OFF except SW1-1 = ON

For Cooling Only – all switches OFF except SW1-1 = ON and

SW2-1 = ON.

10. Configure the fan coil “Easy Select” Printed-Circuit Board

following the instructions on the indoor unit’s installation manual.

11. Configure the thermostat to operate as a single stage cooling and

heating (DO NOT configure the thermostat as a Heat Pump).

NOTE:

Follow the indoor and outdoor unit’s general installation instructions.

The T1 (Return Air Temperature) sensor should be near or on the indoor unit

on the air inlet side. The thermistor should be installed pointing down into the

duct between 2.5 ft (0.75 m) and 4 ft (1.2 m) from the return side of the fan

coil. Use a ½” drill and insert the thermistor no less than 6 in (15 cm) into the

duct and seal air tight around the cable.

Auxiliary Heater on an FV4C:

Refer to and follow the steps of the FV4C Fan Coil Installation

Instructions manual:

1. Wire W2 from the thermostat directly to the FV4 fan coil. See

Figure 11 - FV4C Fan Coil Wiring with 1- Speed Heat Pump (page

7) in the FV4C Installation Instructions manual.

Do not remove the jumper on the fan coil between W1 and W2

2. Re-configure the wall thermostat to control the electric heat as a

2nd stage heat W2.

3. Use the FV4 standard molex 12-pin connector to connect the

Auxiliary Electric Heater element.

NOTE:

When an auxiliary electric heater is connected and active by

W2 from the thermostat, the fan coil keeps blowing air regardless if

the outdoor unit is operating under

DEFROST

mode.

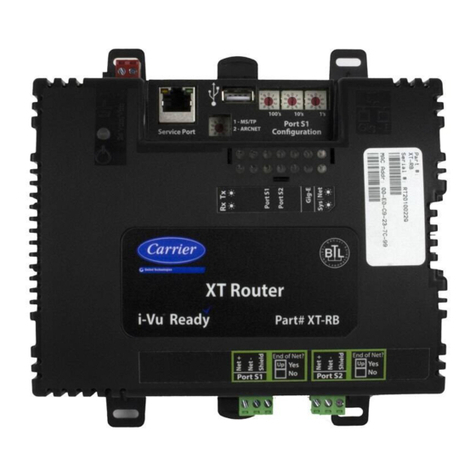

Fig. 13 — Wiring Diagram for FV4C Fan Coil Unit

When the outdoor unit is matched with a Residential fan coil and brazing

the piping on the fan coil side is required, it is NECCESSARY to flow

nitrogen into the system while brazing the line set since a filter drier is not

recommended for use with these condensing units.

CAUTION

W2

Thermostat

70

G

G

G

FV4C

Indoor Unit

L1

L2

24V

D

H

R

W

1

W

2

Y

1

YY

1

G

O

C

Dash line

means

disconnect

transformer

Power supply from outdoor unit disconnect.

Two wires are line voltage and the other is a

Power supply from indoor unit

BUS BAR

GROUND