Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 111 Catalog No. 533-396 Printed in U.S.A. Form 33CN-1T Pg 1 1202 11-02 Replaces: New

Book 1 4

Tab 11a 13a

Controls Operation and

Troubleshooting Instructions

CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION CONSIDERATIONS . . . . . . . . . . . . . 1-5

Default Address and Baud Rate . . . . . . . . . . . . . . . . . . 1

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

I/O Type Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . 5

CONFIGURATION TABLES . . . . . . . . . . . . . . . . . . . . .5-11

Alarm Service Configuration . . . . . . . . . . . . . . . . . . . . . 5

Service Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Time Broadcast Configuration . . . . . . . . . . . . . . . . . . . 7

Holiday Configuration Screens. . . . . . . . . . . . . . . . . . . 8

Time Schedule Configuration . . . . . . . . . . . . . . . . . . . . 8

Points Display Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Occupancy Maintenance Table . . . . . . . . . . . . . . . . . . . 9

CSM III INTERFACE REQUIREMENTS . . . . . . . . .11,12

Chiller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CCN Control Variables . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CONTROL ALGORITHMS. . . . . . . . . . . . . . . . . . . . . .12,13

Control Modes (Shutdown/Local/

CCN/Stand-Alone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chiller Start/Stop Function . . . . . . . . . . . . . . . . . . . . . . 12

Chilled Water Set Point Reset Function . . . . . . . . . 13

Demand Limit Function . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alarm Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

GENERAL

The CSM Chiller Interface allows chillers not manufactured

by Carrier and older Carrier chillers to communicate over a

Carrier Comfort Network (CCN) in order to become part of a

system controlled by a Chiller System Manager III (CSM III).

NOTE: The CSM Chiller Interface is NOT compatible with

the Flotronic™ System Manager.

The CSM Chiller Interface provides hardwired control of

chillers using industry standard I/O methods, such as thermistor

sensor inputs, discrete outputs driving field-supplied relays, and

0 to 10 vdc or 4 to 20 mA control signals. The CSM III supports

a service function (CCN/Local) to allow a chiller to be run

under local control without disturbing the overall control

system. Stand-alone control functions are enabled if CSM III

communications fail. The Chiller Interface provides alarm

messages, display tables, and configuration tables that are

compatible with standard CCN interfaces.

The Chiller Interface can be installed on centrifugal com-

pressor, screw compressor, and reciprocating compressor

chillers manufactured by Carrier, Trane, York, McQuay, and

others, providing those chillers meet the Chiller Interface’s I/O

requirements. One Chiller Interface is required for each indi-

vidual chiller. A pictorial representation of the CSM III/Chiller

Interface system is shown in Fig. 1.

CONTROLS

The Chiller Interface provides the following functions:

• allows a non-CCN equipped chiller to participate in a

multiple chiller system with CSM III (up to 8 chillers)

• provides chiller start/stop, chilled water reset, and

demand limiting control functions

• provides a Time Schedule backup mode for local control

and in the event of CSM III communication failure

(stand-alone mode)

• provides CCN user access (through configuration and

display screens) and CCN alarm messages

• provides adjustable communications baud rate from

9600 (default) to 38,400 bps

The Chiller Interface must be installed on the same CCN

bus as the CSM III. The pump control must be provided by the

native chilled water plant controls and is not provided by the

CSM Chiller Interface.

Chillers to which the Chiller Interface is connected must

support specific input types such as contact closure for chiller

start/stop, and 0 to 10 vdc or 4 to 20 mA inputs for chilled

water set point reset and demand limiting.

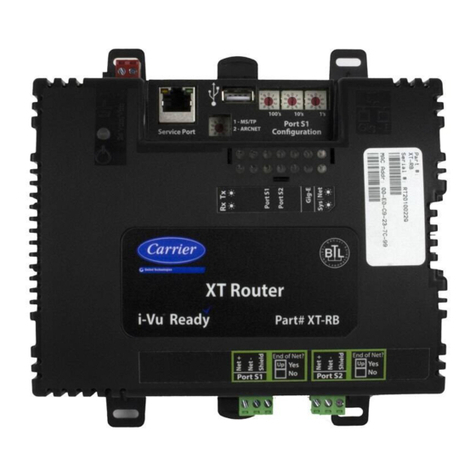

The Chiller Interface consists of an outdoor rated version of

the Comfort Controller 1600 module (CC1600) with special-

ized software. The module is connected to the CCN (Level II

Bus) through its primary communication port (RS-485). The

module’s I/O channels are connected to the native chiller con-

troller and to sensors installed at the chiller.

INSTALLATION CONSIDERATIONS

The Chiller Interface is field-installed in a standard CCN

enclosure and powered from a standard CCN power supply.

All installations must comply with local wiring codes.

The Chiller Interface can be returned to its factory configu-

ration by installing a LID cable jumpered between CCN RJ-11

and I/O RJ-11 and cycling power. To perform a reset, the

Chiller Interface must be disconnected from the CCN bus.

Also, the CCN address will default back to 0, 1.

Figure 2 shows the location of the power connector.

Figure 3 shows the location of the communication connector.

Default Address and Baud Rate — The CSM Chiller

Interface’s default address is 0,99 (bus number, system element

number). Default baud rate is 9600 bps. The address and baud

rate can be set using Address Search in Network Service Tool IV

or Service Pack.

Carrier Comfort Network

CSM Chiller Interface