Specifications subject to change without notice.

Read and become familiar with these instructions before beginning

installation.

SAFETY CONSIDERATIONS

Read these instructions thoroughly and follow all warnings or cautions

included in the literature and attached to the unit. Consult local building codes

and National Electrical Code (NEC) for special requirements. Recognize

safety information.

This is the safety-alert symbol . When you see this symbol on the unit and

in instructions or manuals, be alert to the potential for personal injury.

Understand these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety-alert symbol. DANGER identifies the

most serious hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal injury or death.

CAUTION is used to identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or operation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS........................................................1

OVERVIEW .....................................................................................1

DIMENSIONS..................................................................................2

CLEARANCES ................................................................................2

INSTALLATION .............................................................................3

SYSTEM CONFIGURATION SCENARIOS .................................3

WIRING ...........................................................................................8

DIP SWITCHES CONFIGURATION.............................................11

WIRING DIAGRAM .......................................................................13

APPENDIX 1 - COMPATIBILITY CHART...................................14

APPENDIX 2 - PIPING ADAPTER BUSHINGS/REDUCERS.....15

APPENDIX 3 - FV4C TRANSFORMER........................................15

APPENDIX 4 - ADDITIONAL REFRIGERANT CHARGE FOR

CONVENTIONAL FAN COILS .....................................................15

APPENDIX 5 - FV4C AIRFLOW DELIVERY ..............................16

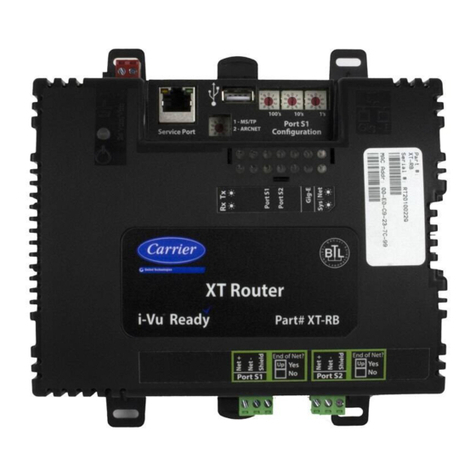

OVERVIEW

The 24V INTERFACE KIT is used to connect:

A Single or Multi-zone Ductless System to a 3rd party single stage

conventional thermostat.

A Single Zone Ductless Condensing Unit 38MA*R with an approved

Fan Coil. For other applications, consult your Ductless representative.

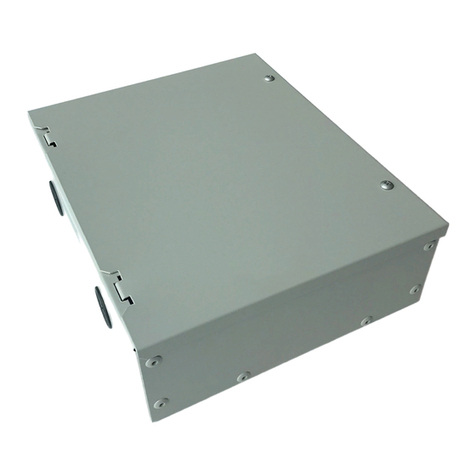

Fig. 1 —24V Interface

NOTES: Images are for illustration purposes only. Actual models may be

slightly different.

Table 1 —Kit Contents: Confirm the following parts are included

Table 2 — Field Supplied Components: Prepare the following assemblies on site

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Before beginning any modification or installation of this kit, be sure

the main electrical disconnect is in the OFF position.

Ensure power is disconnected to the fan coil unit. On some systems

both the fan coil and the outdoor unit may be on the same disconnect.

Tag the disconnect switch with a suitable warning label. There may

be more than one disconnect.

WARNING

EQUIPMENT DAMAGE HAZARD

Failure to follow this warning may result in equipment damage.

Do not install the wired controller in an area subjected to excessive

steam, oil or sulfide gas. Doing so may cause the controller to deform

and/or fail.

CAUTION

INSTALLATION

Entrust the distributor or authorized professionals to install the unit.

Installation by unskilled persons may lead to improper installation,

electric shock, or fire. Re-installation must be performed by

authorized professionals. Non-compliance may lead to electric shock

or fire.

CAUTION

No. Description Qty Remarks

1 Control box 1 N/A

2 Installation Manual 1 N/A

3 Screws 3 M4X20 (for wall mounting)

4 Wall Anchors 3 For wall mounting

7

Return Air Thermistor Assembly

(Hybrid Solutions) (RCD part

number 11201007003448)

1

Required and installed near

or on the unit and on the air

inlet side

8

16ft. (5m) Return Air Thermistor

Assembly Extension Wires (RCD

part number 17401204010126)

1

For a Return Air

Temperature Sensor on

Hybrid Solutions

No. Description Qty Type Remarks

1 Switch Box 1 N/A N/A

2Wiring Tube (insulating sleeve

and tightening screw) 1 N/A N/A

KSAIC0301230 24V Interface Kit

for Ductless Systems and Hybrid Solutions

Installation Instructions