2 © 2021 Carrier

TABLE OF CONTENTS

DESCRIPTION .............................................................................................................................................................1

SYSTEM INFORMATION...........................................................................................................................................4

TECHNICAL DATA NXTSD507HD...........................................................................................................................5

TECHNICAL DATA NXTSD512HD...........................................................................................................................6

ORDERING INFORMATION......................................................................................................................................7

MOUNTING NXTSD507HD .......................................................................................................................................8

Method ......................................................................................................................................................................8

Cutout........................................................................................................................................................................9

Template..................................................................................................................................................................10

MOUNTING NXTSD512HD .....................................................................................................................................11

Method ....................................................................................................................................................................11

Cutout......................................................................................................................................................................12

WIRING ......................................................................................................................................................................13

Terminals.................................................................................................................................................................13

Wiring .....................................................................................................................................................................14

Ethernet/USB ..........................................................................................................................................................16

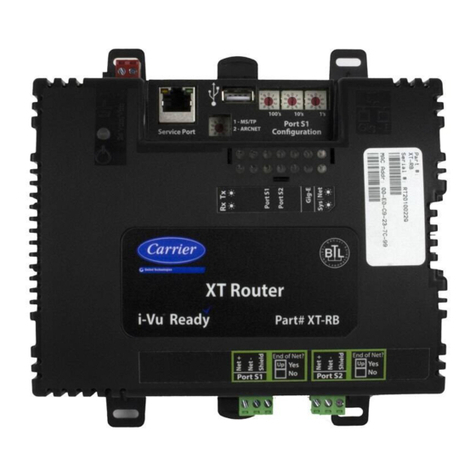

ESTABLISHING COMMUNICATION .....................................................................................................................17

OVERVIEW SCREEN (NXF4000 and PPC4000) .....................................................................................................18

INFORMATION SCREEN (NXF4000 and PPC4000)...............................................................................................19

GENERAL SETTINGS (NXF4000 and PPC4000) ....................................................................................................20

Changing values ......................................................................................................................................................20

SYSTEM SETTINGS..................................................................................................................................................21

ALARMS ....................................................................................................................................................................22

Active ......................................................................................................................................................................23

Log ..........................................................................................................................................................................24

Fault History............................................................................................................................................................25

HELP ...........................................................................................................................................................................26

SYSTEM .....................................................................................................................................................................27

Log ..........................................................................................................................................................................28

Security ...................................................................................................................................................................29

Options ....................................................................................................................................................................31

Miscellaneous .....................................................................................................................................................31

Language ............................................................................................................................................................39

Screen Saver / Date.............................................................................................................................................40

Network ..............................................................................................................................................................41

Modbus Data Server ...........................................................................................................................................42

OVERVIEW SCREEN (BurnerLogix) .......................................................................................................................45

WIRING DIAGRAM SCREEN (BurnerLogix)..........................................................................................................46

FAULT HISTORY SCREEN (BurnerLogix)..............................................................................................................47