Power Transformer Wiring -- An individual, field-

supplied, 24 vac power transformer is highly recommended for

each System Pilot. Transformers must be UL Class 2 rated.

Standard applications require a 24 vac transfonnel: rated at

40 va typic_d. All transformer secon&uies are required to be

grounded. Use only stranded copper conductors for _dl wiring

to the System Pilot.

Wiring connections must be made in accor&mce with NEC

(National Electric_d Code) and local codes. Ground one side of

the transformer secondary at the transformer location. Connect

the system ground of the transformer to the System Pilot

terminal JPI-I (GND). Connect the 24 VAC- side of the

transformer to the System Pilot terminal JP1-2 (24 VAC-).

Connect the 24 VAC+ live side of the transformer to the

System Pilot terminal JP1-3 (24 VAC+). See Fig. 1. The power

supply is 24 vac at 60 Hz _+15%, 10 va minimum.

NOTE: Do not run sensor or communication wiring in the

same conduit with line-voltage wiring. Do not run 24-vac

wiring in the same multi-conductor cable used for sensors

or communications.

Perform the following steps to connect the power

transformer:

1. Install the field-supplied transformer in an electrical

enclosure that conforms to NEC and local codes.

2. Connect 24 vac from the transformer as shown in the

wiring diagram (Fig. 1). Be sure to observe polarity

when connecting the transformer power. The grounded

terminal must be connected to the transformer ground

terminal as shown.

If the system pilot is powered with the salne transformer

as the other devices, be sure that polarity is maintained

and that adequate power is available for all devices. Never

power half-wave and lull-wave devices on the same

transformer or &_mage may occur to one or both devices.

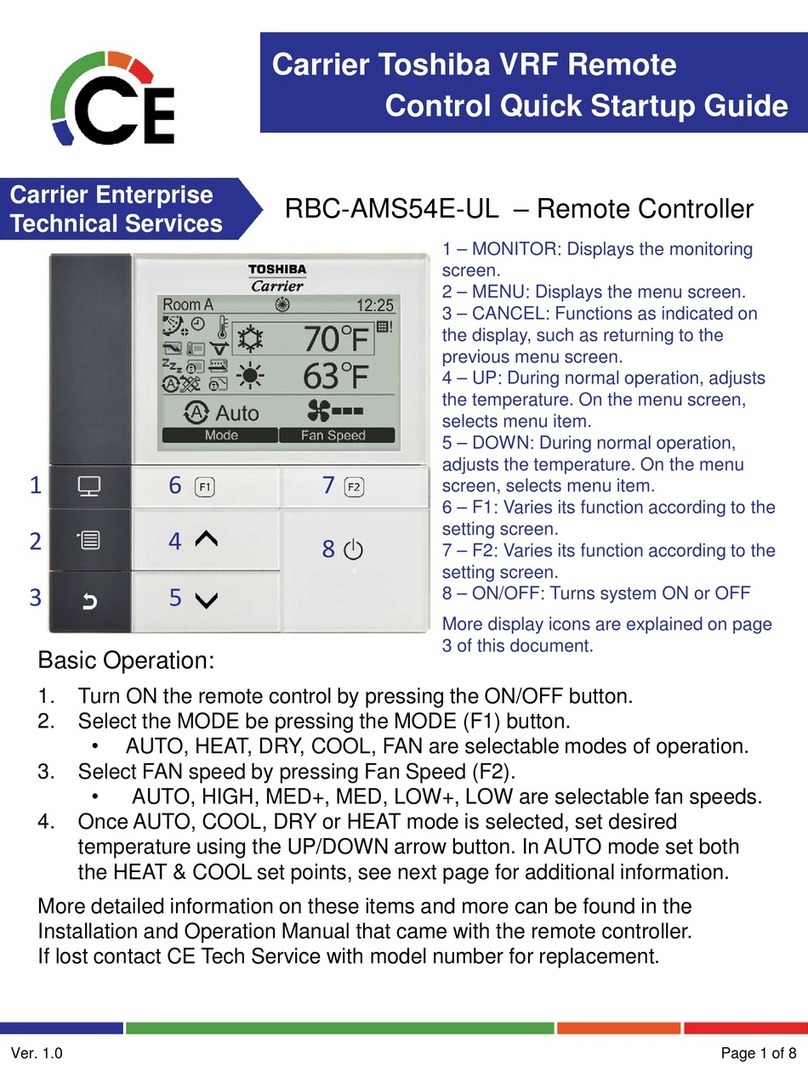

Carrier Network Communication Bus Wiring --

The System Pilot connects to the bus in a daisy chain ammge-

ment. The System Pilot may be installed on a primary C;urier

communication bus or on a local bus wired to a VVT Zone

Controller's COMM2 port. When many System Pilots _ueused,

connecting to a loc_d bus is recommended. See Fig. 2 for local

bus wiring to a zone controllel:

At tiny baud (9600, 19200, 38400 baud), the number of

controllers is limited to 128 zones maximum. Bus length may

not exceed 4000 1l, with no more than 60 total devices on any

1000-ft section. Optically isolated RS-485 repeaters _ue

required every 1000 ft.

The fiLst device in a netwoN connects directly to the bridge

and the others ;ue wired sequenti_dly in a daisy chain fashion.

Refer to Fig. 3 for an illustration of Cturier Communication

Bus wiring.

COMMUNICATION BUS WIRE SPECIFICATIONS --

The communication bus wiring is field-supplied and field-

installed. It consists of shielded three-conductor cable with

drain (ground) wire. The cable selected must be identic_d to

the communication bus wire used for the entire network. See

Table 1 for recommended cable.

Table 1 -- Recommended Cables

MANUFACTURER CABLE PART NO.

Alpha 2413 or 8463

American A22503

Belden 8772

Columbia 02525

NOTE: Conductors and drain wire must be at least 20 AWG (American Wire

Gage), stranded, and tinned copper. Individual conductors must be insulated

with PVC, PVC/nylen, vinyl, Teflon, or polyethylene, An aluminum/polyester

100% foil shield and an outer jacket of PVC, PVC/nylon, chrome vinyl, or

Teflon with a minimum operating temperature range of -20 C to 60 C is

required.

CONNECTION TO THE COMMUNICATION BUS

1. Strip the ends of the red, white, and black conductors

of the communication bus cable.

2. Connect one end of the communication bus cable to

the communication port labeled COMM2 (if connect-

ing on a local bus).

When connecting the communication bus cable, a

color code system for the entire network is recom-

mended to simplify installation and checkout. See

Table 2 for the recommended color code.

Table 2 -- Color Code Recommendations

CON BUS WIRE

SIGNAL TYPE COLOR

+Red

Ground White

Black

PLUG PIN

NUMBER

6

5

4

3. Connect the other end of the communication bus cable

to the terminal block labeled Carrier Network Connec-

tion on the System Pilot. See Fig. 1. Following the

color code in Table 2, connect the Red (+) wire to

Terminal JPI-6 (CCN+). Connect the White (ground)

wire to Terminal JPI-5 (CCN GND). Connect the

Black (-) wire to Terminal JPI-4 (Carrier Network

Connection -).

4. If connecting to a Carrier communicating network bus,

connect additional devices in a daisy chain fashion,

following the color coded wiring scheme in Table 2.

Refer to Fig. 3.

NOTE: The communication bus drain wires (shield) must

be tied together at each device. If the communication bus is

entirely within one building, the resulting continuous shield

must be connected to ground at only one single point. If the

communication bus cable exits from one building and enters

another building, connect the shields to ground at a light-

ning suppressor in each building where the cable enters or

exits (one point only).

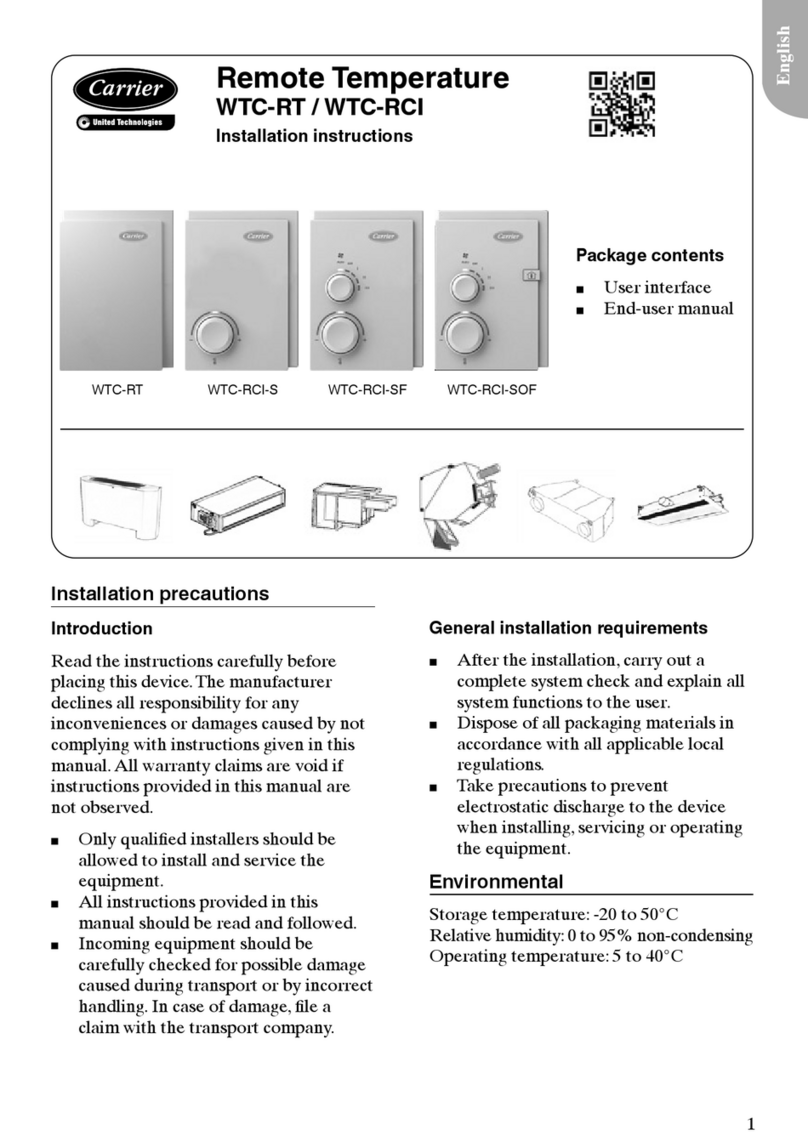

Mounting -- There are two options for mounting the Sys-

tem Pilot to the w_dl, recess mounting or surface mounting. The

System Pilot will snap together with either the Recess Mount

or the Surface Mount backpkite.

NOTE: The recess mount backplate is provided with the

System Pilot.

RECESS MOUNT--This provides the thinnest mounting

configuration (See Fig. 4). The backplate containing the

recessed terminal block can be mounted directly to the wall by

cutting a hole 13/4-in. wide by 21/8-in. high. Mark location and

cut hole in wall. Ensure the System Pilot location is acceptable

before cutting tiny holes in wall.

SURFACE MOUNT -- This provides surface mounting con-

figuration, which allows use of a small hole in the wall. Surface

mount backplates may be purchased separately. (See Fig. 5.)

Attach backpkite and the assembly will mount directly to the

wall, requiring only a small hole in the wall _dlowing the wiring

connection to pass through.

Once the System Pilot is secured to wall with the backplate

assembly (snapped together), care must be taken not to

bend or break the interlocking tabs when removing. Gently

remove System Pilot by rocking up/down until interlocking

tabs release.

DECORATIVE BEZEL- A decorative bezel may be pur-

chased separately in boxes of 10. See Fig. 6. The bezel can be

used to hide any marks/screw holes left from the previous

thermostat. This decorative bezel can be used in either the

recess or surface mount installation by snapping it onto back of

recessed mount backplate or surface mount backplate before

securing to wall.