CONTENTS

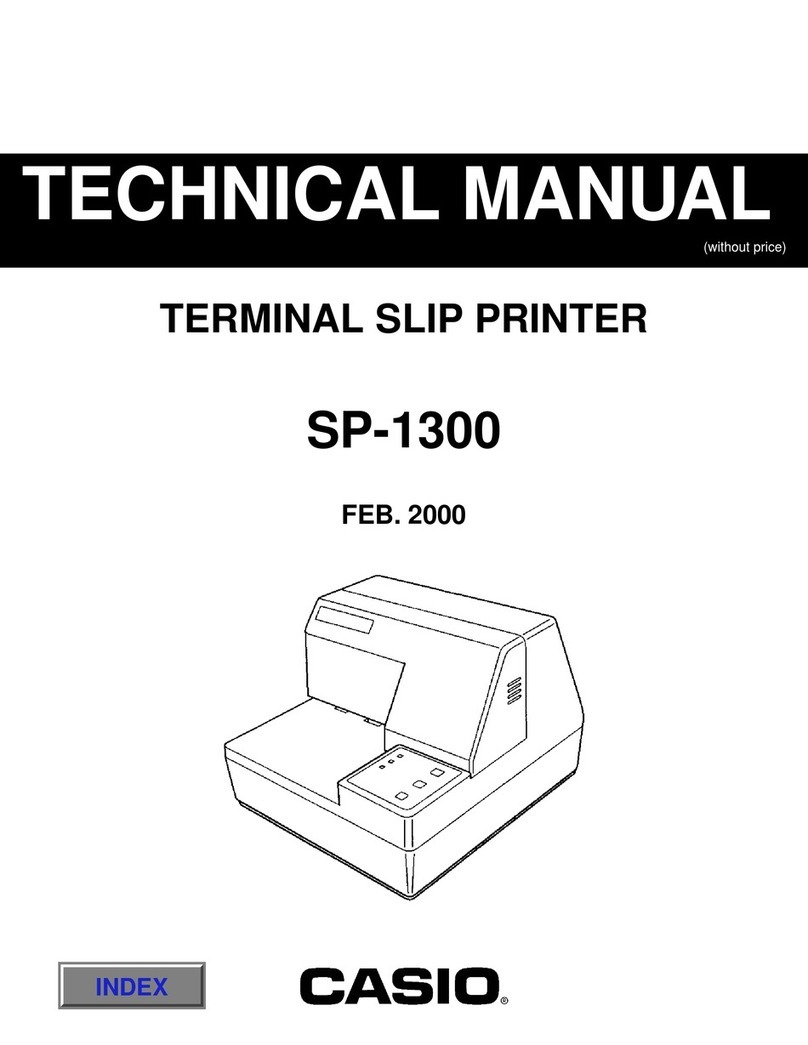

Chapter 1 Features and General Specifications ......................................................1

Features .......................................................................................................................... 2

Printing Specifications ........................................................................................................ 2

Character Specifications..................................................................................................... 3

Paper .................................................................................................................................. 4

Auto-cutter .......................................................................................................................... 5

Paper Roll Supply Device................................................................................................... 5

Receive Buffer .................................................................................................................... 5

Electrical Specifications...................................................................................................... 5

Ribbon Cassette .................................................................................................................5

External Dimensions and Weight........................................................................................ 6

Environmental Specifications ............................................................................................. 6

Reliability ............................................................................................................................ 7

Safety Standards ................................................................................................................7

Printer Installation Position ................................................................................................. 7

Hardware Configuration ................................................................................................ 8

Main Unit Specifications ............................................................................................... 9

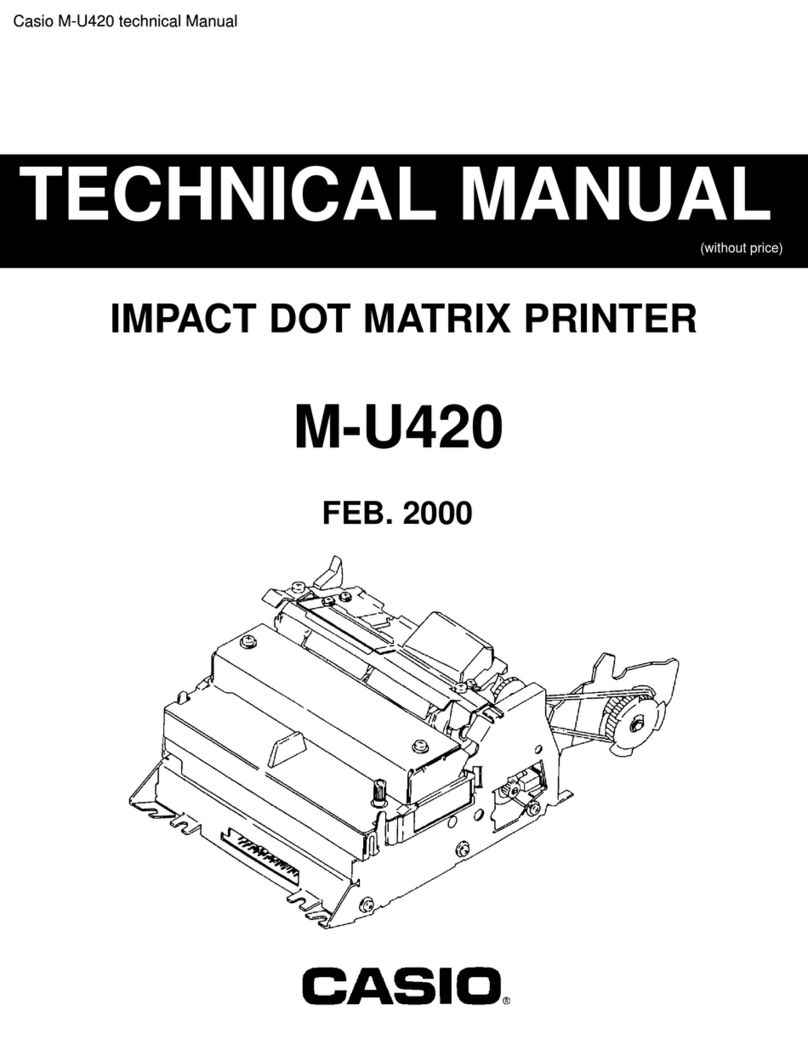

Paper Feed Motor............................................................................................................... 9

Carriage Motor.................................................................................................................... 9

Print Head Unit ................................................................................................................... 9

Home Position Sensor........................................................................................................ 9

Paper End Detector .......................................................................................................... 10

Paper Roll Near-end Detector (Optional) ......................................................................... 10

Connectors ................................................................................................................... 10

Interface Connector .......................................................................................................... 10

Power Supply Connector...................................................................................................11

Drawer Kick-Out Connector...............................................................................................11

Interface ........................................................................................................................ 13

RS-232 Serial Interface .................................................................................................... 13

RS-485 Serial Interface (option) ....................................................................................... 16

IEEE 1284 Parallel Interface ............................................................................................ 16

Buttons and Switches ................................................................................................. 19

Power Switch....................................................................................................................19

Panel Button ..................................................................................................................... 19

DIP Switches ....................................................................................................................20

Panel LEDs ................................................................................................................... 22

Self-test......................................................................................................................... 22

Error Processing.......................................................................................................... 23

Printer Operation When an Error Occurs........................................................................... 23

Data Receive Error ............................................................................................................ 23

Buffer Full Printing ...................................................................................................... 23

Detectors and Printing ................................................................................................ 23

Hexadecimal Dump...................................................................................................... 24

Performing a Hexadecimal Dump..................................................................................... 24

Options .........................................................................................................................24

External Power Supply PS-170 ........................................................................................ 25